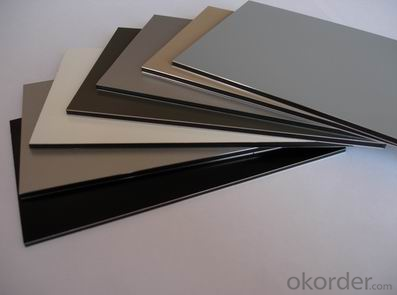

ALUMINUM PE COMPOSITE PANEL DIFFERENT TYPE

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Breif details

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Jinxiang

Model Number: JX 6001

Usage: Outdoor

Function: Anti-Static, Antibacterial, Fireproof

Surface Treatment: Anodized, Brushed, Foil Decoration, Mirror, PE Coated, Printing, PVDF Coated, Nano Coated

Panel thickness: 2mm/3mm/4mm/5mm/6mm

Aluminum thickness: 0.10mm/0.12mm/0.15mm/0.21mm/0.30mm/0.40mm/0.50mm

Width: 1220mm,1250mm,1500mm,1570mm

Coating: PE, PVDF,NANO

Color: over 300 kinds of color (as per customer's requirement)

Core: Breakable,Unbreakable,Fireproof

Length: 2440mm (according to customers' request)

Standard size: 1220x2440mm

Logo: OEM (customer's logo and brand are welcome)

Name: Aluminium Composite Panel

2. Main Feature

. Excellent fireproof characteristics

Super peeling strength

Perfect cold resistance performance

Excellent surface flatness and smoothness

Superior weather, corrosion, pollutant resistance

Even coating, various colors

Superior impact resistance

Lightweight, easy to process and installation

Easy to maintain

3.Main Specification

PE/PVDF coated Aluminium Composite Panel Specification:

| Width(mm) | 1220 | 1250 | 1500 | |||||

| Length(mm) | 2440 | Or according to customer's request | ||||||

| Panel thickness(mm) | 2 | 3 | 4 | 5 | 6 | |||

| Aluminum thickness(mm) | 0.10 | 0.12 | 0.15 | 0.18 | 0.21 | 0.3 | 0.4 | 0.5 |

| Coating | PVDF | PE | Brush | Mirror | Glossy | Wood and stone texture | ||

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

Q: Can you supply samples for us?

A: Yes we can send you sample with few quantity

Q: What is the delivery time?

A: One month since the payment will be received

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

Q: Can you supply samples for us?

A: Yes we can send you sample with few quantity

Q: What is the delivery time?

A: One month since the payment will be received

Q:What is the main use ?

Gas piping, cables, building materials, etc (this product fills a gap

in the domestic construction materials field, with performance

indexes superior to panels manufactured overseas)

Curtain wall decoration for buildings where security is important,

such as airports, hospitals and research centers

Curtain wallboards for outside walls of normal buildings

5.

- Q:Kunming fly forest board and love grid plate which a good?

- Can these two be better than that? One is imported from Germany, one is Kunming, the core can see the gap

- Q:Is there a sheet with a flame retardant function?

- The market should still have a lot of, after all, now everyone's security awareness are put up. Before the concern of the wood industry's fire-retardant board seems to be doing this, you can see.

- Q:Which brand advantage is more prominent?

- Plate brand is also a lot of, but many people do not know. Also have to understand the major plate brands, in which the "home of the United States" in the plate this piece is done reputation, many people have praise.

- Q:Now I'm going to calculate a display panel for the material sheet, and I'm ready to calculate the square of the plate! The data is: length [1200MM] width of [750MM] thickness of [480MM] material name is [white light paint] how to calculate how many squares to use it? Jaya! Say it! I put the remaining 5 points all to You say that one of them.

- Is it not your cabinet High: 1200 Width: 750 Depth: 480? The cabinet you have to open. There are two side panels, a roof a floor, a backplane, but you have to know there is no solid and activities Plywood. According to your size: 1.2 * 0.48 * 2 = 1.152 0.75 * 0.48 = 0.72 1.2 * 0.75 = 0.9 Probably square: 2.78. Just a mao count, there is a board where I have not subtracted.

- Q:Now I have to come up with a E1 level test report, but I want to buy E0 level, but the staff of Loulan Ya said that there is no E0 level of this concept. Is this true? Please industry experts to answer the next

- "E0" grade, "E1" grade refers to the formaldehyde emission limit level of environmental standards. "European standard 'E0' class", that is, every 100 grams of plate, formaldehyde emission ≤ 5 mg According to the relevant provisions of the state, furniture, formaldehyde emission to "E2" level can be sold, and by the manufacturing process and other factors, our country basically did not really "E0" class furniture And the world, whether it is composite material or solid wood panels do not exist "zero formaldehyde" sheet metal furniture So that "E0 level" furniture basically does not exist, zero formaldehyde is only legend Can only say that the furniture industry has a small amount of brand of sheet metal furniture, formaldehyde content is far lower than the national standard, is green building materials.

- Q:Comparison of fire and water of the plate

- Solid wood is the best, the most upscale

- Q:Malacca and the big board, fir board which is more suitable for the cabinet? Experienced to talk about it

- Currently on the market there is a board core for the fir Glulam, the surface of melamine finishes the board, the overall is also good, should gradually replace Malacca, the price is higher. Now we are talking about environmental protection, any kind of board are graded, there are good and bad. We can under the plate price, different levels of board price difference is quite large, and the other furniture production of the overall process and accessories for environmental protection will also have an impact, like the decorative plate furniture, edge technology, solid wood furniture, paint environmental Type, etc., when we buy the price is on the one hand, their actual needs and cost is king

- Q:What is the quality of the snowboard?

- Chevrolet board can be comparable with the wood, and can be sawing, planing, can be nailed, sticky, but also has no deformation without cracking without painting (a variety of colors) and other special features; and low foam sheet can be welded, Ink printing and can also be used saw, drill, milling and other methods for machining.

- Q:What is the concept of negative ion sheet?

- Plate by nano-catalyst technology, can be released to the human body beneficial negative ions Negative oxygen ion radicals can kill a variety of respiratory infections, to prevent infection The sheet has the following functions: Dust: the dust in the air to gather, the strong collection of suspended particles, to prevent inhalation of the body, cut off the bacteria vector. Deodorization: remove all kinds of life smell, smell, improve the living environment. Smoke: the rapid elimination of oil in the air smoke, dust, put an end to secondhand smoke. Toxic: Remove all kinds of toxic chemical volatile gases in the air, eliminate "invisible killer". Health care: improve work efficiency, eliminate fatigue, improve heart and lung function, enhance the body immunity. Beauty: the epithelial cells with a negative charge, so that the bacteria lost the ability to attack the cells to keep the skin smooth. In addition to static electricity: life is generally positive static, will bring risks to the human body and mind health, negative ions and effective in this static. Add the living space of negative ions and reactive oxygen species: brain refreshing, eliminate fatigue, focus, improve work efficiency, prevent air conditioning disease, improve human living environment, so that human return to nature.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ALUMINUM PE COMPOSITE PANEL DIFFERENT TYPE

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords