Aluminum panel composite plate calcium silicate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

- Option:

- 1220*2440

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum panel composite plate

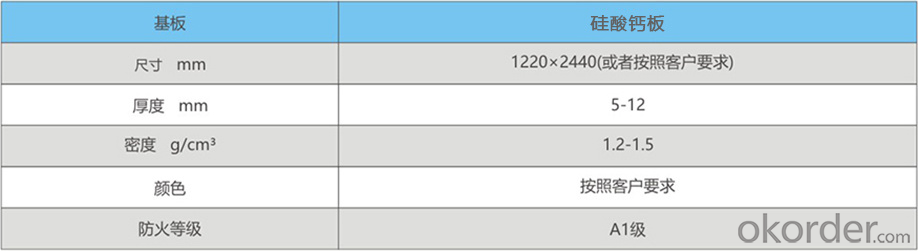

Aluminum panel composite plate With calcium silicate plate as the substrate, the high-performance aluminum plate coated with high weather resistance fluorocarbon paint or inorganic magnetic paint is organically combined with it, supplemented by high temperature pressure, static pressure maintenance and other processes.

Product features

● good durability, great stiffness and impact resistance

● stable performance and a service life of more than 20 years The perfect combination of ● rigid substrate and flexible finishes has better mechanical and structural properties Good optical performance

●aluminum panel is a diffuse surface coating without glare under light conditions; the special semi-suboptical treatment of the aluminum panel surface is particularly important in ensuring the safety of tunnel driving

Product application

Widely used in urban rail transit platform, urban tunnel, airport, etc

- Q:Calcium silicate board material production methods which

- The synthesis of the dynamic process is carried out under stirring, the synthesis temperature is higher than the static process, and under pressure conditions. Dynamic process is simple, no gelation process, the product capacity is small, the performance is better, can be high temperature (1000 degrees Celsius) of the xonotlite products and ultra-light products, but need to bring the device with high pressure vessel , Equipment and process conditions require a higher energy consumption and investment are higher. At present, foreign countries use this method.

- Q:What is the difference between the board and the silicon board?

- Et board is also known as calcium silicate board. Silicon calcium board is based on the improvement of gypsum board products

- Q:Calcium silicate board 6MM how much money one

- Calcium silicate board specifications are generally: 5mm 9MM, 12MM. 5mm in the general 20 yuan or so.

- Q:Calcium silicate board production mode, the copy method and the quality of the comparison method, which prawn know

- At present, with the improvement of process control level, the gap is not so big, the capacity of the upstream slurry method by increasing the width of the blanket, the quality of the press and template surface treatment to enhance, but the relative equipment investment will be large ( Japan and Taiwan can not copy the template, but because of the differences in the level of process control, the majority of domestic product copy quality products can not reach the level of the Japanese level). There are two ways to integrate business, such as Etienne, with a blanket, the production of different products can be two ways to switch at any time.

- Q:Calcium silicate with quartz powder is the number of requirements! How much silicon content?

- Calcium silicate board preparation of quartz powder with the general requirements: Silica content: greater than or equal to 93 (%) Melting point 1600 (℃) Mohs hardness: conventional Common specifications: 100 - 325 head Color: gray, grayish yellow Suitable for the production of calcium silicate board and other calcium silicate products

- Q:What is the size and classification of calcium silicate board? How do we choose the specifications for their own calcium silicate board?

- Calcium silicate specifications are conventional specifications, that is, 1220x2440, or the use of conventional specifications more money, you want to be more expensive

- Q:Calcium silicate board how to deal with smooth surface, that is, I would like to foil in the calcium silicate board, is to be very common to paste the bottom,

- Directly to the skin more trouble, the domestic I have not seen which business to do so, foreign Japan to do a lot, especially calcium silicate anti-static floor, are PVC or melamine paper paste. There are ways to do, you can find some floor or furniture to do a small factory, OEM can do small batch, the surface do putty layer and then sanding to the need for smoothness, and then paste the skin like, the effect is the same The

- Q:Silicon calcium board ceiling workers how much money a square meter

- Local wages vary, the above is for reference only. More with your local workers to inquire about the price is clear.

- Q:How to distinguish between the color of calcium silicate board is good or bad

- Identification of calcium silicate board with fire: Calcium silicate board is a fire board, so the direct use of a well-burned plate, then there is no role. Before the fire must use the way to get the plate, pay attention, do not directly use the saws saw, if it is thin, hand directly snapped, if it is thick plate, use the hammer to break it. After the break, you will send now cross-section inside covered with small lines, these small lines or that is asbestos, or that is the plant fiber, if it is asbestos, then burned after the announcement will affect the burning smell, If it is plant fiber, then burned after the paper will announce the taste of burning. A smell can easily distinguish this calcium silicate board is not rich in asbestos.

- Q:Home wall with a good board or silicon calcium board

- Calcium silicate board can be widely used in building wall, wall, ceiling, roof and ventilation pipes and gymnasium, theater, conference room sound-absorbing panels and fire wall panels, can also be used for a variety of special purpose industrial facilities, such as Highway insulation wall, enclosure, power plant cooling tower leaching board, construction works with a permanent template, steel structure of the fire board, trains and ships compartment board, the activities of housing board, large-scale composite MILL With an outer plate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum panel composite plate calcium silicate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

- Option:

- 1220*2440

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches