Aluminum Lithographic Coil Sheet for Printing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminum Lithographic Coil Sheet for Printing

Aluminium Lithographic Coil (also called PS panel) is a professional material that used for the printing application. It has high surface quality requirement. It is produced by surface degreasing solution, drying, photosensitive coating treatment and cutting to the specification that customer required.

This products are popular with national and overseas markets for its good quality and competitive price. such as southeast Asia, North America,Europe and so on. If you are interested in our products, welcome to contact with us

We professionally offering PS plate with below characteristics:

1 Photosensitive Coating

Consisted by imported photographic emulsion and resin, the coating layer of the plate have outstanding alkaline resistance, superior stability, high sensitive and increased adjusting flexibility as well as better resolving power.

2 Vacuum ventilating layer

With tiny ventilating grain layer on the surface, the vacuuming time during exposure can be greatly decreased, as well as preventing the proportion of tiny dots from exposuring to vague.

3. Water Receptive Layer

Excellent water reception capability speeds up the ink-water balance procedure and helps to reduce water absorption during printing process. Superior water retaining capability do effectively prevents non-image areas of the plate from scumming and avoids paper from distortion. Consequently, the printing quality improved

4. Multi Grain Layers

Multi grain layers polish up water receptive property of the non-image areas on the plate. It increases the ink /water adjusting flexibility, make sure the developing performance of the tiny dots. It also strengthens the dots’ adsoption power to the coating layer, which can consequently extend the run-length of the plate.

5. Anodic-Oxidized Layer

A durable and strong oxidized surface formed after the anodic oxidation process on the aluminium material, which can help to prolong the run-length. This layer can also resists the corrosive effect done by the correction fluid.

2. Technical Specifications of Aluminum Lithographic Coil Sheet for Printing

Thickness:0.14-0.27mm

Material (alloy):1050, 1060

Temper:H18, H19

Width(mm):500-1600;

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

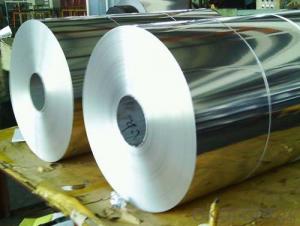

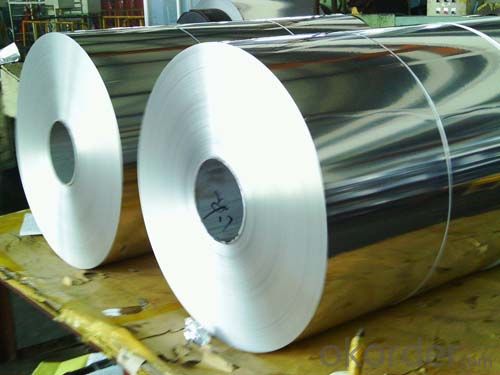

4. Image of Aluminum Lithographic Coil Sheet for Printing

5. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:I am looking at 2001 and 2002 Lincoln LS V8'sI keep seeing this quot;LSEquot; model that has some improved cosmetic features but no mention of performance upgradesWhat other different items did the LSE come with over the standard LS V8's?

- The only difference is in the trim package To be specific, the LSE gives you this: LSE Appearance Package available on V-8 Sport only includes unique 17 7-Spoke chromed-aluminum wheels, modified front and rear fascias and side rocker panels, unique fog lamps, color-keyed grille surround with chrome vertical bars, color-keyed license-plate surround, rear deck lid spoiler, all-red tail lamps, LSE badge, LSE floor mats and unique wood interior appliquesWell, it doesn't exactly give it, you pay about $3,000 more for it.

- Q:I have tried it and it seems to make it worse.

- I've had a little bit of succcess with foilNot reynolds wrap, but foil art foilReynolds wrap stuff is too thickYou can buy the cheap, dollar store brand.it works okay because its really thinYou need to rub all the dirt, debris, etc off the stone.a whisk broom works really wellThen, cut the sheet to wrap over the top and go all the way to ground levelUsing a paint brush.I have a 1/4 inch soft bristle one.you smooth the foil over the stoneWhen you begin to see where indentations are, concentrate on them using the paintbrush to poke the foil into the indentationsIts a real pain, a long, slow processIf you go quickly, either the foil crushed/ridges and you can't get a readingI found, really, its better to do a rubbing using thin paper and charcoalSometimes all thats left it a dent, and using the letters around it and its basic shape you can extrapoltate the word.

- Q:Can I wrap BBQ ribs in parachment paper instead of aluminum foil?

- Do you mean yawnsIf so, I don't knowIf you meant yarns, please explain.

- Q:There is an aluminium tube containing a silica cylinderThe silica cylinder acts as a thermal tap to control?the flow of liquid down the tubeAt 0 degrees celsius, the cylinder has a diameter of 20mm, there is an exact fit, and no liquid flowsCalculate the size of the gap between cylinder and tube at 100 degrees celcius(linear expansivity if aluminium 0.000026 K ; linear expansivity of silica 0.000008 K) Please show working

- Any codes? you would be wanting a test gadget to examine for codes and computer screen parameters to get the solutionsIt appears like the coolant temp sensor to meadditionally examine for vacuum leaks.

- Q:My wheel cracked in the outer lip, im a welder and itll be easy to fix, from a welders stand point, i should leave some weld on the outside, but what about from an automotive POV? I know inside you're not supposed to leave weld on it because the bead won't sealWhat if I leave a small weld on the outside just in case it wants to start cracking again?

- if you think it's to cold for you then you should bring your pet inside and for short haired dogs like pits really if you won't stay out all day or night in it then why should they

- Q:I am looking for a list of things I will need such as olive oil, flour, flour etc.basically all the stuff I would need to cook with.

- NO-it says put ON baking sheet.A baking sheet is a metal tray, pretty much flat although it may have 3 upturned edges and one flat edge so you can slide off whatever you have just cooked on it-cookies,cakes, a pie,whatever.It is usually made of metal and its purpose is to distribute the heat evenly to the bottom of your masterpiece so it is evenly cookedIf you are using it to cook a pie- either home-made or bought, the pie will already be in some kind of a dish so the sheet does what I've already said AND catches any drips if the filling boils over inside the pastry case.

- Q:My hair is a few inches past my shouldersI blow dry and straighten it regularly (I know, that's bad)But, I do drink plenty of water, and use a leave-in spray conditionerI also make sure that my shampoo and conditioner have minimal alcohol levelsMy hair has become SO dry thoughI've stopped straightening it for 2 weeks nowIt's not really helping thoughDoes anyone have any reccomendations? A deep conditioning product, or home remedyanything! -Also, I heard vitamin E is a good moisturizerwould that be good to spray in?

- I use the Bead Head line called Control Freak it works really wellGood Luck with keeping your hair straight.

- Q:How does the air inside an empty aluminum can compare to the air outside of the can? Is it equal, lower, or higher?

- If they come in a paper bag I will fold the end over and store in the bottom drawer in the kitchen until they are short enough to store in the fridge Dune

- Q:my 92' chevy truck heater core appears to be clogged,even though water flushes good when a hose is usedi think water is not flowing completely thru itis there anyway to cleanout deposits? i've tried vinegar water,but airflow is not hottercore appears to be aluminum and is in good shape.

- It depends how you define a low carb dietANY low carb diet I design would not have fruits or whole grains in itAnd only certain veggiesTypically on a low carb diet, one must supplement fiber (metamucil) daily to stay regular.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Lithographic Coil Sheet for Printing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords