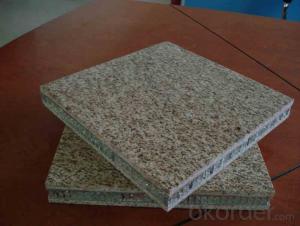

Aluminum Honeycomb Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

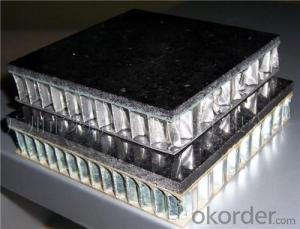

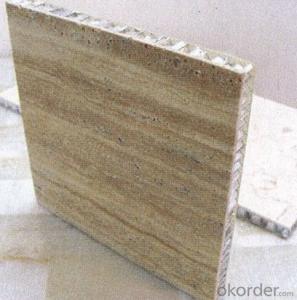

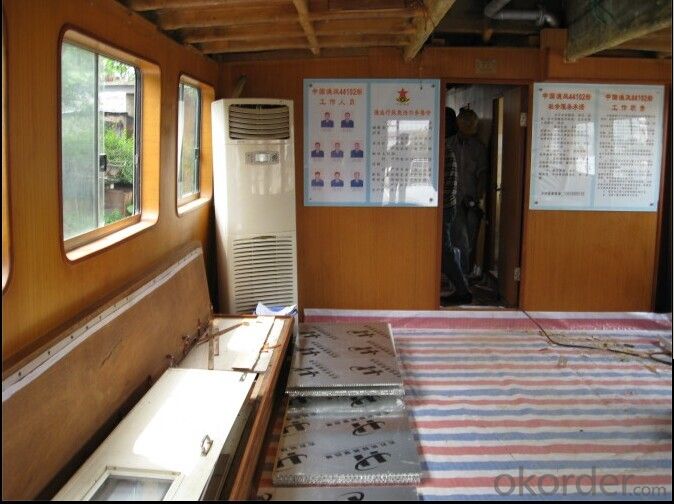

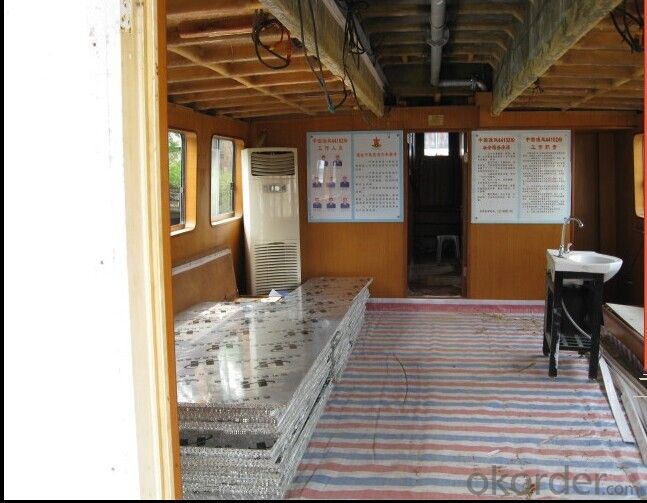

As the stone aluminum honeycomb board has the advantages of light weight, small pollution, save the radiation characteristics of stone material, board size is large, can be used to the ceiling, curtain wall, interior walls, the ground, more and more widely used in buildings, vehicles, ships and other decorative decoration。size: according to customers' request

- Q:Can aluminum plate prevent radiation?

- Depends on the installation method, not directly put aluminum, aluminum can also be a role in the ground. Grounding is to connect the aluminum plate with the earth, so that the electromagnetic waves on the aluminum plate will be absorbed into the power of aluminum and flow to the ground, if not ground will produce the other side of the aluminum field, is tantamount to go through. In fact, grounding is very simple, if the installation of metal screws directly with the aluminum contact, but also with the cement wall contact can be considered ground, although not a good grounding. If the wall is wood or the like insulation material can not, then there is a screw, if it is the kind of hole in the wall into the plastic sleeve is not enough, because the plastic insulation.

- Q:Which brand is better?

- Aluminum-plastic plate auspicious chanting

- Q:OKorder 3M glass curtain wall adhesive tape and aluminum-plastic plate Lvkou Ban and aluminum veneer special double-sided tape where there?

- US 3M company in OKorder designated agent 3M tape and glue labels and other products distribution and double-sided tape cutting and precision cross-forming! My company's tape has a professional curtain wall with double-sided adhesive.

- Q:The required materials and prices together to make it clear, gray often thank you!

- Materials required: aluminum-plastic panels, angle aluminum, angle code, foam sticks, sealants, self-tapping screws,

- Q:Aluminum panels are used in what areas, can not be more detailed.

- The aluminum-plastic panels were first developed by the German company Aiusingen and later improved by Forken and Aloca. 90 years later, the product quality gradually stable, reached a high level. As the aluminum-plastic plate is composed of two different materials (metal and non-metallic), it retains the original composition of materials (metal aluminum, non-metallic polyethylene plastic) the main features, but also to overcome the lack of raw materials , And then get a lot of excellent material properties. Such as luxurious and beautiful, colorful decorative; weathering, corrosion resistance, impact resistance, fire, moisture, heat insulation, sound insulation, light resistance; light, easy processing, easy handling, quick construction and other characteristics. These properties for the aluminum-plastic plate opened up a broad application prospects.

- Q:Why aluminum-plastic composite board in the cutting of the inner aluminum and polyethylene plastic, should retain not less than 0.3mm thick polyethylene plastic?

- To prevent the processing and dry hanging construction, aluminum-plastic plate when the outer corner of the fold burst.

- Q:I want to open a small aluminum-plastic plate factory, how much money

- Then the five major raw materials, protective film, aluminum roll, polymer film, paint, core material, if only on the composite line, then the paint and aluminum roll can be saved, you can directly purchase. The protective film, polymer film and plastic need to buy from the.

- Q:Aluminum plate construction offer how much

- Aluminum-plastic board construction package package materials offer two intervals: indoor decoration is generally about 280 yuan, 380 yuan outside the room. Qing workers 60-150 yuan a square meter.

- Q:Will the decoration door with aluminum-plastic plate how construction, construction process, thank you friends

- And then use silicone tape. Finally torn film.

- Q:Guiqiu, how can there be aluminum-plastic plate, ah, need to recover ah, please help Oh, thank you

- Looking for manufacturers

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Honeycomb Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords