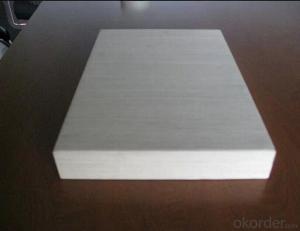

Aluminum honeycomb panel6

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum honeycomb panels, suitable for civil building, vehicle decoration etc.. Is the application of aviation, aerospace materials in the field of civil building. The whole process is completed in modern chemical plant, using hot press molding technology, due to high thermal conductivity aluminum skin and honeycomb value between the inner and outer aluminum skin, thermal expansion and contraction synchronization; a small hole honeycomb aluminum skin, make board inside gas can flow freely; slidably mounted in heat bilges cold shrink button system does not cause structural deformation

Use

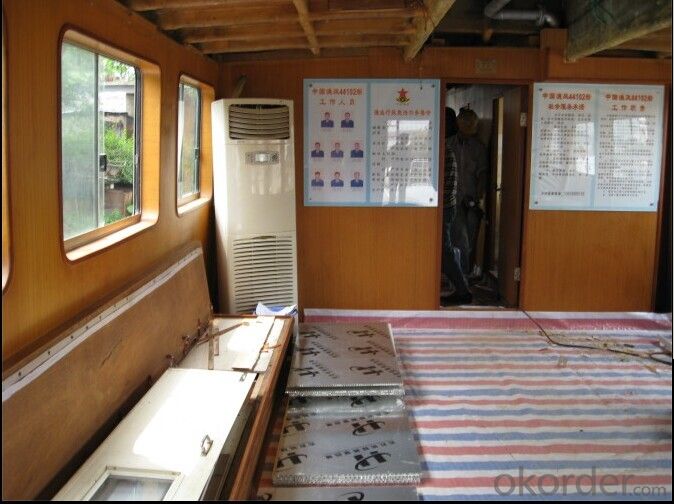

(1) the building curtain wall and external wall hanging board

(2) interior decoration project

(3) billboard

(4) the ship building

(5) the aviation manufacturing industry

(6) indoor partition and merchandise display platform

(7) commercial truck and container vehicle car body

(8) the bus, train, subway and rail transit vehicles

(9) on very strict environmental requirements of modern furniture industry, aluminum honeycomb board to do the processing of furniture materials, is to choose a good material for the new century, its green quality completely non-toxic, let the furniture business in the processing of furniture, the less unnecessary environmental program; in addition, aluminum honeycomb panel the panel can be diversified such as wood, aluminum plate, gypsum board, Dali natural stone, can be made into honeycomb panel, easy material selection.

(10) aluminum honeycomb board partition: partition aluminum honeycomb panel, broke the previous traditional partition model, with its noble, pure and fresh, style style, won the middle and high-grade office space market share.

The performance advantage

(1) the fire: Aluminum incombustible material.

(2) corrosion: aluminum honeycomb panel is coated with epoxy fluorocarbon treatment, with strong corrosion resistance. Salt fog spray for 48 hours without pinholes, cracks, no blistering.

(3) environmental protection: honeycomb plate belongs to pure aluminum made products, volatile any harmful gases, no radiation and can be completely recycled, environment-friendly products 100 percent.

(4) aluminum honeycomb board is easy to dismantle and remove the plate assembly, not bad. Because of its light weight, easy to transport solid can be transported to different places and repeated utilization. This is the other partition plate can not match.

- Q:Aluminum veneer and aluminum-plastic plate which is good? Will aluminum veneers corrode?

- The two production methods are different, different processing methods.

- Q:Aluminum plate 50 wire thickness what it means

- 4mm refers to the total thickness of the plate, 50 wire that the thickness of aluminum plate, that is 0.50mm standard units that the curtain wall with aluminum composite panels there are some requirements, such as coating recommended PVDF fluorocarbon resin, film thickness of 25 microns and so on The

- Q:That if i switch to colored glass? Is this a lot of money? If I do 14 square black glass ceiling about how much budget?

- Indoor ceiling with aluminum-plastic board generally 3 mm thick, not more than 60 yuan per square meter of aluminum-plastic plate material quality has been quite good. Fire board is cheaper. But the fire-type aluminum composite board, then expensive. 120 yuan / square meters around it

- Q:OKorder Liupanshui there is no auspicious aluminum-plastic plate to sell, to the new material of the aluminum-plastic plate, the price is not too expensive, the best manufacturers, because I amount

- You can look around, not necessarily in the Liupanshui find ah, Kunming has a cloud like building materials is aluminum-plastic plate manufacturers, sent to Liupanshui not far

- Q:Home decoration has several commonly used plate classification

- MDF, also known as fiberboard, wood fiber and plant fiber as raw materials and watering bonding.

- Q:4mm thick aluminum-plastic plate, two-layer aluminum alloy thickness of 0.5mm price is how much?

- Brand manufacturers should be the price of 200 yuan / square meters or so. Some manufacturers may offer a lot lower.

- Q:OKorder Huayuan Fluorocarbon aluminum plate aluminum thickness 50mm each price is how much? Best to have pictures!

- Aluminum-plastic plate thickness 50MM, made it wrong! Should be 50 silk, which is 0.50MM. But to know your specific specifications, the following offer for reference only Fluorocarbon 1220MM * 2440MM * 4MM * 0.50 / 0.50MM 380 yuan / Zhang or so.

- Q:What is a composite function building material?

- Wood-plastic composite material is based on sawdust, wood chips, bamboo chips, and other primary biomass materials as the main raw material, with a certain percentage of plastic base material, the special process after processing a reversible recycling, covering a wide range, Product variety, the shape of a variety of basic materials.

- Q:Is there a kind of wall called aluminum?

- Outside the aluminum plate it

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum honeycomb panel6

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords