Aluminum Formwork for Concrete Wall Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Whole Aluminum Formwork Description

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

Aluminum Formwork is widely used in highway,railway,bridge,tunnel and shearing wall,etc. It is with light weight and smooth for surface concrete and popular in constructions .

2. Main Features of Aluminum Formwork

- Lighter weight but high bearing capacity.

The allowable pressure from fresh concrete is 60KN/m2 with the thickness of 65mm.

- Manual transportation can be achieved, greatly reduces the aggregate cost.

- Perfect design, excellent produce and well welding make sure the flatness of concrete surface.

- It is with the advantages of standard design, excellent applicability and interchangeable.

- Simple, safe and fast.

- No rust corrosion, easy maintenance, and high turnover rate.

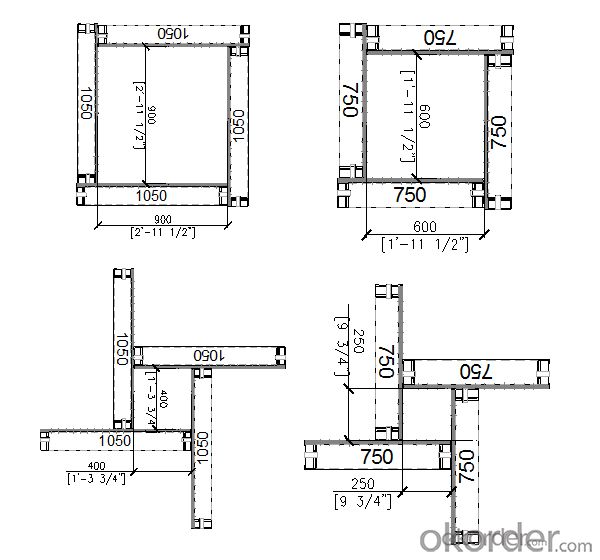

3. Aluminum Formwork Specifications

- MaximumColumn Size: 900 x 900mm (2’-11.5”x 2’-11.5”)

- DesignConcrete Pressure: 1,800 psf (90 kN/m2)

- StandardPanel Width 900mm, 750mm & 600mm (2’-11.5”,2’-5.5” & 1’-11.5”)

- StandardPanel Height: 3.0m, 2.4m, 1.2m

4. Producrion & Applications

5. FAQ of Aluminum Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q:What is the change in the aluminum template?

- The turnover of the aluminum template is determined by the use of performance. The use of aluminum template system to improve the overall construction efficiency of the construction industry, including in the building materials, artificial arrangements are greatly saved a lot of aluminum template, also known as aluminum alloy template, is made of aluminum alloy building templates, to solve the traditional The existence of defects in the template, greatly improving the construction efficiency.

- Q:Now the domestic use of aluminum template project more?

- Construction of aluminum alloy template construction advantages are: 1, the construction period is short, four to five days can be a layer; 2, re-use more than 200 times, effectively reduce costs; 3, artificial reduction of 30%, construction convenience, high efficiency; The template 2 times the bearing capacity, good stability, high bearing capacity;

- Q:In the Sheng-aluminum template installation workers, how to develop prospects

- Sheng Tong on my feeling is the same as prison, in addition to front-line staff (prisoners), what is the leadership (guards), every day is the workshop, dormitory, dinner time is only half an hour, the company provides working hours if 12 hours, The time to stay in the workshop every day in more than 13 hours, especially hard to force, can not stand the tube, temper a little irritable advice do not go, afraid you can not control their own K

- Q:What is the development prospect of aluminum template design?

- I estimate that the next three years, to do the aluminum alloy template design is still very popular, but I still recommend not to circle their own in the aluminum template design circle, because the industry is really small .... technology is mutual Plagiarism (I do not have heart burst shady), if he really want to be a designer, I recommend to the road to the building to go ....

- Q:Whether a shear wall aluminum template and wood template can be mixed

- Mixed with the two kinds of templates will be fixed in different ways, the construction of the security caused a certain impact; intersecting joints prone to the wrong layer and honeycomb; two templates expansion coefficient, strength, water retention will not cause the same shear Wall as a whole;

- Q:Aluminum template of the aluminum template advantage characteristics

- In areas with high urbanization, the following technical advantages can be demonstrated: 1) Short construction period. Aluminum template system for the quick-release mold system, a set of normal construction of the template can reach four days a layer, and can be better to start the construction of the pipeline, greatly improving the construction schedule, saving management costs. 2) the number of repeated use, the average use of low cost. Aluminum template system using the overall extrusion of aluminum alloy profiles to do the raw materials, a set of specifications can be used to modify the construction of more than 300 times. A set of template purchase prices are spread out than the traditional template to save a lot of cost. 3) convenient construction, high efficiency. Aluminum template system assembly is simple, convenient, the average weight of about 20kg, completely by the manual handling and assembly, do not need any mechanical equipment to help, and the system design is simple, the workers get started speed and template flip speed quickly. Skilled installation workers per person per day can be installed 20-30 square meters, significant savings in labor costs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Formwork for Concrete Wall Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords