Aluminum for Pre-Insulated Aluminum Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum for Pre-Insulated Aluminum Panel

1.Structure of Aluminum for Pre-Insulated Aluminum Panel

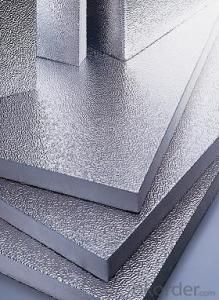

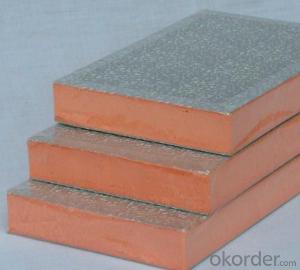

Air ductwork supply is pre-insulated aluminum panels constructed of both aluminum and Poly-isocyanurate. The sandwich panels are comprised of expanded Poly-isocyanurate rigid foam board, faced on both sides by aluminum foil.Ducting is the key part of any central air-conditioning system. It is similar in function to the arteries and veins in the human body as it helps in regulating the temperature in a building. The material used for making ducts for air-conditioning is constantly evolving in order to satisfy the demand for higher thermal efficiency, eco-friendliness, and increased energy savings. Many different materials and systems such as magnetite composite, PVC and so on have been developed as alternatives to the galvanized sheet metal used traditionally. But pre-insulated ducting materials is by far the most popular ducting system in use today. It is essentially a panel made with an insulating material such as PIR (Polyisocyanurate), PUR (Polyurethane) or Phenolic foam material sandwiched in between two layers of aluminium foil. Such a foam panel is easier than traditional galvanized sheet metal to manipulate for complex designs and lighter than its predecessors for installation. These qualities in addition to the fact that it has a much higher thermal efficiency than galvanized sheet metal make it an ideal material for fabricating Airconditioning ducts in harsh climates like the Gulf. Its application has been gradually extended to every type of air distribution system: industrial and commercial.

For construction of air ducting in HVAC systems, the Polyisocyanurate (PIR), PUR (Polyurethane) and/or Phenolic foam panel with 45kg/m3 density, coated with 80/80µm thick embossed aluminum foil have two panel types:

The air ducts fabricated using ALU 80/80 panels can be installed in plants:

with air speed up to 15m/s

with pressure up to 1000Pa

indoor

The air ducts fabricated by using ALU 80/200 panels can be installed in plants:

with air speed up to 35m/s

with pressure 1750Pa

outdoor

2.Main Features of Aluminum for Pre-Insulated Aluminum Panel:

Air Duct Panel / Pre-insulated Duct Panel / HVAC Duct Panel :

HVAC Aluminum Foil Duct Board

1. Be used for HVAC Duct system;

2. BS 476 Part 6&7 Class 0.

3. Low thermal conductivity.

3.Aluminum for Pre-Insulated Aluminum Panel Images

Our embossed aluminum sheet/Coil series include:

1.diamond embossed aluminum sheet/Coil

2.orange peel embossed aluminum sheet/Coil

3.stucco embossed aluminum sheet/Coil

4. Aluminum for Pre-Insulated Aluminum Panel Specification

Air-conditioning Areas Exposed to weather

Thickness of panels 20 Mm 30 Mm

Thickness of aluminum 80/80 Microns 80/200 Microns

Density of the foam 44-48 Kg/m3 42-48 Kg/m3

Finishing of aluminum Embossed Embossed

Dimension Length: 4meter Width: 1.2meter

Note: Both sides of the aluminum foil are lacquered with a 3g/m2 weatherproof and ultraviolet ray protection polyester lacquer.

Certificate: FORM A, CO ,FORM E ,FORM B ,MTC, SGS and ROHS(client paid for it), MTC

Surface Quality: without any dent, scratches, oiliness , oxidation .

Chemicial composite and Machinary Property: Meet with GB/T, JIS,ENAW, ASTM standard

Month Capacity: 5000MT/month

exporting port: Tianjin, Shanghai

payment: TT or LC at sight

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long for your delivery time?

Commonly 30 working days can be served. If you need the products urgently, we can shorten the delivery time into 20 days.

3. Where the Panels can't be used?

As extractors in the kitchen, as chimneys for smoke or chemical laden smoke

As transportation for solids

Outside temperature range -35ºC and +110ºC

Air speed >15m/s for 20mm thick panel and >35m/s for 30mm thick panel

when the negative or positive pressure inside the duct is: 20mm thick panel >1000Pa and 30mm thick panel >1750Pa

- Q:What do you call the tool used to remove the waste material at the back of a hole you've drilled?

- Ah, I use a deburrer most every day at workPlastic handle, weird little blade that rotatesWorks great on aluminum, a little tougher on steelFor steel, I tend to go straight to a round needle file.

- Q:When you cook something, lets say a pizza, in the oven, and you put it on aluminum foil rather than a cookie sheet....how come the aluminum foil isn't too hot to touch when you go to pull it out?

- different metals transfer heat differently, and aluminum isn't a metal that is a good conductor. So just because it's a metal doesn't mean it will get hot.

- Q:.to handle the sample, how would you determine the sample's density?

- If you are sure that it's pure aluminum, you need to find the densityThe mass (or weight) can be determined on a simple balanceDepending on the sample's shape, you can determine the volume by simple water displacement (unless this is not allowed) If you can't touch it or handle it, you have a problemAbout the only other thing to do is some type of comparison to objects of known mass/volume.

- Q:I am going to be going for 4 day camping with about 30 girls and we are going to a campsite right on top of the kern riverI need some good pranks, 2 foil dinner recipes, one with shrimp one without, and some secret sister ideas, thanks!

- Why is it when people ask camping questions they almost never say whether they have to pack stuff in out or whether they are car camping, which means access to refrigeration, electricity, etc? Without this crucial information it is hard to answerAlso, while I know where the Kern River is, what does right on top of the kern river mean? You are camping in the water? Its origin? next to it? Makes no sensefoil dinner recipes implies you will have a campfire, unless you are talking about pouring boiling water into freeze-dried foil packets I'm guessing you intend to use aluminum foil in the coals of a fireBut you want shrimp! Which you will have to keep cool until the cooking, so I'm guessing you have some sort of refrigeration at the campsite See the problem when you fail to provide needed facts? How about jars of shrimp cocktail, crackers, cheese and wine? No cooking or refrigeration requiredFor the other foil meal, shoot some jackrabbits, bring butter herbs/spices, wrap them (after gutting skinning) in foil with the goodies and put the packets under the coals of the fire for about an hourRabbit doesn't have much fat, so include plenty of butterYou could do the same with steak and potatoes/onionsI don't know what secret sisters are, I assume it is not obscene ;) Pranks and camping don't go well together, because there are knives, fire and alcohol already, so caution is requiredCampsites on the Kern River have been booked up for months, especially for a large groupSo you have had plenty of time to work this stuff outCrowdsource these questions among your fellow campers A group of 30 is a pretty big group, sounds like funPerhaps ask the pranks question in the jokes and riddles section? I hope the adventure goes well for youI hope you have researched that river, there are places with Force 5 rapids, which are very serious.

- Q:What diameter must a copper wire have if its resistance is to be the same as that of an equal length of aluminum wire with diameter 3.26mm?

- aluminum wire with diameter 3.26mm Resistance of a wire R = ρL/A ρ is resistivity of the material L is length in meters A is cross-sectional area in m? A = πr? resistivity Cu 17.2 (nΩ-m) resistivity Al 28.2 (nΩ-m) 1 = Al 2 = Cu ρ1L1/A1 = ρ2L2/A2 lengths are the same ρ1/A1 = ρ2/A2 ρ1/ρ2 = A1/A2 28.2/17.2 = π(1.68)?/πr? 28.2/17.2 = (1.68)?/r? r? = (1.68)?17.2/28.2 r? = 1.72 r = 1.31 d = 2.62 mm .

- Q:Items that I can buy for not to much at storesIt has to be wrapped around a plastic water bottle, with hot water insideThe water has to stay hot for around 40 minsThank you

- Bubble wrap and styrofoamStyrofoam is best, and you can find old used coffee cups in the trash for thataluminum foil also helpsWrap the bottle in the foil, then layers of styrofoam, as thick as you are allowed There is a type of styrofoam, or plastic with bubbles in it, in any case, that is flexibleYou can find it used as packing materialCheck at a UPS or similar storeOtherwise use standard styrofoam cut to fitOr even styrofoam pieces held on with packing tapeOther tricksLet the bottle sit with hot water in it for a while to warm up the bottle and the inside of the insulationKeep the top closed tightly, and also insulatedInsulate the top and bottom as well as the sides .

- Q:Is it the same as aluminum? I am doing an assignment on Iceland, and they are the largest producer of primary aluminum in the world per capita.

- Aluminium that is produced from ore, as opposed to secondary aluminium which is produced from recycled aluminium products.

- Q:Its an 1/8th inch thick

- i wouldn't recommend a cold air intake just because it goes down to the bottom of the car and gets the cold air under the car so when it rains and you go through a puddle depending on how low your car is you will suck water into your intake (BAD) if i were you i would get a ram air intake both are easy to install

- Q:what is robert goddards impacto n the world? how is he important to man?

- you and the kids, should get in this orange!!!

- Q:I want to print pictures from the computer on some blank t shirts and hoodies that I haveI live about 45-90 minutes from New York City in the 07071 area in New Jersey.

- Try bamboo or baby yarnJust feel them when you buy them.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum for Pre-Insulated Aluminum Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords