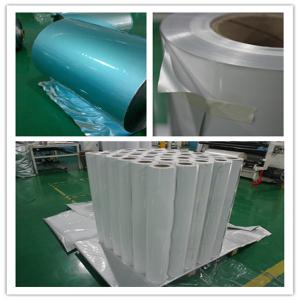

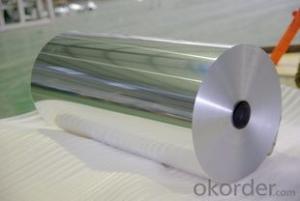

Aluminum foil with polyethylene

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1 Packaging material

2 Material:AL PE PET NY or other materials

3 Max width:1500mm

4 ISO9001 14001

Packaging material

1 About product

1) Materials:

AL/PE

AL/PET

PVC/PE

PP/PE

AL/VMPET

PET/VMPET/PE;

VMPET/PE

PET/PE;

PET/AL/LDPE,

PE/AL/PET.etc.

2) Max width:1500mm; length:customized;

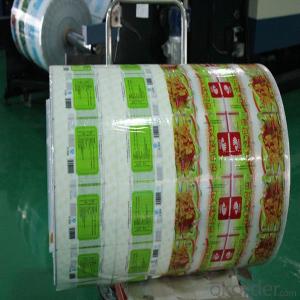

3) Print:1-8 colors;

4) ID:54mm or 76mm;

5) ISO9001,14001;

2 Specifications

1) Aluminum complex film;

2) High strength;

3) Good heat sealing;

3 Feature

1) Smooth and clear surface;

2) Heat resistant, water proof, stable at high temperature;

3) environmentally friendly,no smell and not-toxic;

3 Shape

Can cut into rolls, also pieces ,and tailor made bags of different styles of specification;

4 application:

1,Combine with asphalt materials, and installe on the roof, have waterproof insulation shading effects. Products are Widely used in high-end buildings, villas, color steel tile-roofed house and steel housing.mostly used in Europe and the United States

In addition, Such products are suitable for vacuum packaging of the precision machinery and equipment, precise instrument, automotive parts, electronics,chemical raw materials, pharmaceutical intermediates

all materials are customized as per customers' request

- Q:What is the difference between aluminum foil and aluminum foil?

- The supermarket of the aluminum foil and aluminum foil is the same. (you can see the material description.)

- Q:When the wire is made, it needs a layer of foil inside, and the outside is insulated. Why is that?

- Insulation is done outside to protect or leak electricity.Cable foil is the use of aluminum foil sealing and shielding, single or double coated plastic film, an aluminum foil plastic composite #

- Q:The kitchen faucet is placed at the bottom of the cupboard. It has an aluminum foil paper. It smells great. Is it harmful to the human body? How can I get rid of it?

- There is no harm in foil (Aluminium foil), also known as the Hongkong aluminum foil, aluminum foil, aluminum is a metal flat manufacturing tool, mainly used for kitchen cooking, food containers, or used to make some simple cleaning materials. Thousands of tons of aluminium foil are used around the world for the protection and packing of food, cosmetics and chemicals. Most of the foil is shiny on one side and the other dull. Aluminum foil for food can be wrapped on both sides, and it is generally recommended to enhance the heat transfer effect with bright bread wrap

- Q:What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- A kind of composite heat preservation board with aluminum foil is used in air conditioning and air duct insulation1, the insulation material molded type insulating materials used is moulded polystyrene foam board, also known as EPS, commonly used household appliances packaging materials is the white foam foam board; the extruded insulation material is extruded polystyrene foam board, which is XPS.

- Q:Why can copper foil and aluminum foil shield electromagnetic signals?

- Therefore, they usually back conductive adhesive, otherwise shielding effectiveness is very poor, under normal circumstances, with conductive adhesive copper foil / aluminum foil can reach more than 90dB, with flying conductive adhesive only about 40dB

- Q:How to calculate the aluminum foil material?How can we calculate the number of meters with weight, length and thickness?

- The composites are collectively referred to as base weight (meaning base weight). The simplest and most direct method is to test the total weight of the foil per square meter with a microbalance, and then the total weight is converted

- Q:What size is the aluminum foil bag?What are the commonly used sizes?

- General market of an aluminum foil bag: LED lights, aluminum foil bags, specifications for 0.14*21.5*23.5CMYou can customize what size you want, and you can also print the bag in multi colour, which perfectly reflects the brand effect of the product. You deserve it.

- Q:Car sunshade and black aluminum foil which is good, and the aluminum foil is white or cartoon, mainly considering the shading effect

- In the less hot season, colour patterns can be placed out of the room. If the weather is very hot, the foil can be turned out to ensure the reflection of sunlight. In the purchase before the sun block, it is best to choose to take a sucker, the material should be more hard texture. "Light plate" or "too cheap" front sun block is not enough itself, it is easy to fall, so do not seek cheap. In general, there are brands of front sun block, packaging materials used better, there are special placement of suction cups, sucker is not easily squeezed. Worse brands, ten to one, a sucker is squeezed, and the remedy is to put it in boiling water for a while.

- Q:Aluminum foil for food packaging materials, why?

- Because aluminum foil has smooth surface, light weight, good light shielding, not easy to corrode, non-toxic, easy to process and so on

- Q:I heard that using aluminum foil and salt to add water can make the silver ring bright. Who told me what aluminum foil is and where can I buy it?

- Aluminum foil in the construction of the application is quite obvious, paste on the surface of thermal insulation material, make it more convenient and clean construction, especially the aesthetic degree to a new height. But the effect of different kinds of foil is very different, for example, fire and ordinary are not a grade.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum foil with polyethylene

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords