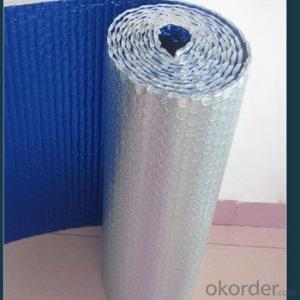

aluminum foil with LDPE for bubble foil insulation production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

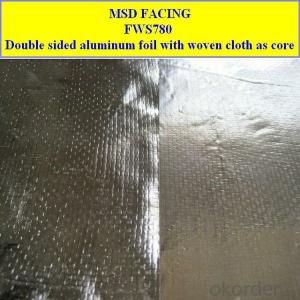

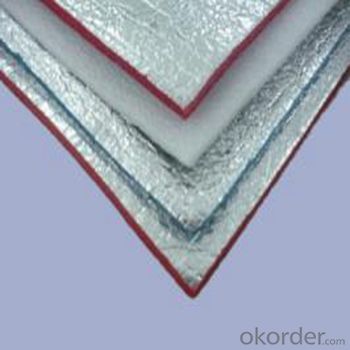

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Burst strength | N | 43 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

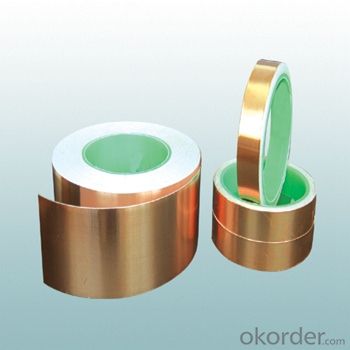

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:What are the roof insulation materials?

- Is made from volatile polystyrene beads containing volatile liquid foaming agent, and a white solid having a fine closed-cell structure which is thermoformed in a mold after being preheated by heating

- Q:I have a vented metal roof. WV winters

- Check into heat tape tied to pipe, with insulation wrapped around that. turns on when freezing temperatures. insulation by itself, will not stop it from freezing if left for long periods without water moving through it. .

- Q:we want to put a model railway up in the loft,and i like the idea of having white plastic cladding throughout up there,my hubby is insulating the roof tomorrow,but he prefers plasterboard,at least the cladding will be maintenance free,

- i think it might be able to pass code if you ever sell the house.i myself would use sheets of white wainscoting.also make sure the insulation if it has a paper backing ,paper faces the room.

- Q:hot because of all the added insulation. Is that what the insulation will do? Someone told me that it will save us on our cooling/heating bills, and that it will be warmer in the winter and cooler in the summer now. Is this true?

- Insulation does not have a "hot" side and a "cold" side. It just slows down the transfer of heat from the inside of the house to the outside of the house and viceversa.

- Q:hi me and my friends made a lounge out of my old tin roof shed we have a tv speakers and a few other electrical goods... since winters on its way we were wondering whats the best and cheapest way to insulate the place note that its a tin rof but has wood under it where the old indulation used to be the place is pretty chilly and sometime damp plz help we dont wanna be freezing our asses off in there thanks :)

- I would look at using the pink insulation if it will fit between the tin roof and the under it, If not, you may have to remove the wood to install the insulation.

- Q:what effect does changing the pitch of a roof have on the insulation properties and durability of a roof?

- Increasing the pitch will of course result in a larger dead air space therefore more insulation. The greater pitch is also less likely to leak but of course more costly to construct as more material is needed. Install vents at the peaks for more efficiency. Shingles will be less likely to be lifted by high winds with the steeper roof also.

- Q:I am really confused about this science stuff! Sustainability is terrible xP

- All versions of insulation are largely air that is kept from moving - air is a good insulator if convection - movement of heated or cooled air due to changes of density - is prevented. This assumes that a vapor barrier and caulking prevent actual air movement through the wall when a wind is blowing. Some insulators are also poor conductors of heat so the connection between inside and outside that might occur is broken. As it happens, glass used in fiberglass and minerals used in rock wool are actually pretty good conductors of heat in solid form but as fine particles and flakes they don't conduct well from one strand/piece to the next.

- Q:I'm thinking of converting my brick walled corrugated iron shed into a changing room for winter hot tub use. I was advised by a friend that the first thing i should do is insulate the roof using glass fibre insulation (the yellow fluffy stuff in the loft) and a simple Plywood ceiling but im not sure how i would stick it to the existing roof (dimensions 170cm x 147cm). So..... how should i insulate the roof of my future changing room????

- If the roof has joists, which I imagine it would, you would put the bats of insulation into those spaces... these can then be stapled into place or if that isn't possible, you can run a wire between the joists to hold the bats in place. If using faced insulation be sure to put the paper side towards the warm area (inside) to prevent condensation.

- Q:House is a bi-level. Recently added storm windows to deck off dining room. Having a new rubber roof installed would like to know if we can insulate ceiling to make the room warmer. What product do you suggest we use. we are getting conflicting answers, some say you can insulate others say the ceiling needs to breath having a rubber roof install. Please advise.

- If you have vaulted ceilings you need to get the right insulation. Basically it wont be as thick and still leave some room between the insulation and the roof for it to breathe. You should be able to get it at any home improvement place.

- Q:I live in central florida. I plan on installing R-30 insulation to the floor of my attic. How effective is it to install reflective insulation to the attic on the roof side? Is it worth the price?

- the best floor insulation is the two on the roof or the 1st floor ceiling, (floor of the attic), no longer the two. If that is already on the ceiling, the attic is vented to the exterior, and insulating the roof could make little or no distinction. Laying one extra 'blanket on the floor is a thank you to bypass in case you prefer to enhance. Insulating a roof will boost the summer season temperature of the roofing, and could adversely result the life of a few components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

aluminum foil with LDPE for bubble foil insulation production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords