Aluminum foil tapes with heat sealing films

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Packaging & Delivery

| Packaging Details: | Packaging, marking, transport and storage Marking Adhesive tape per box should have the following marks: a) Producer name and address; b) Product name and specifications; c) Quantity and weight; d) Date of manufacture or batch number of production; e) Pressure prevention, moisture-roof and sunscreen signs; f) Expiration date. g) If meeting the RoHS requirements, the product packaging is RoHS labeled. Packaging The product is packaged by use of corrugated boxes, and plastic bags are packa |

| Delivery Detail: | AS SOON AS POSSIBLE |

Specifications

applicable to encapsulate the evaporation pipelines for refrigerator, freezer and other refrigeration systems.

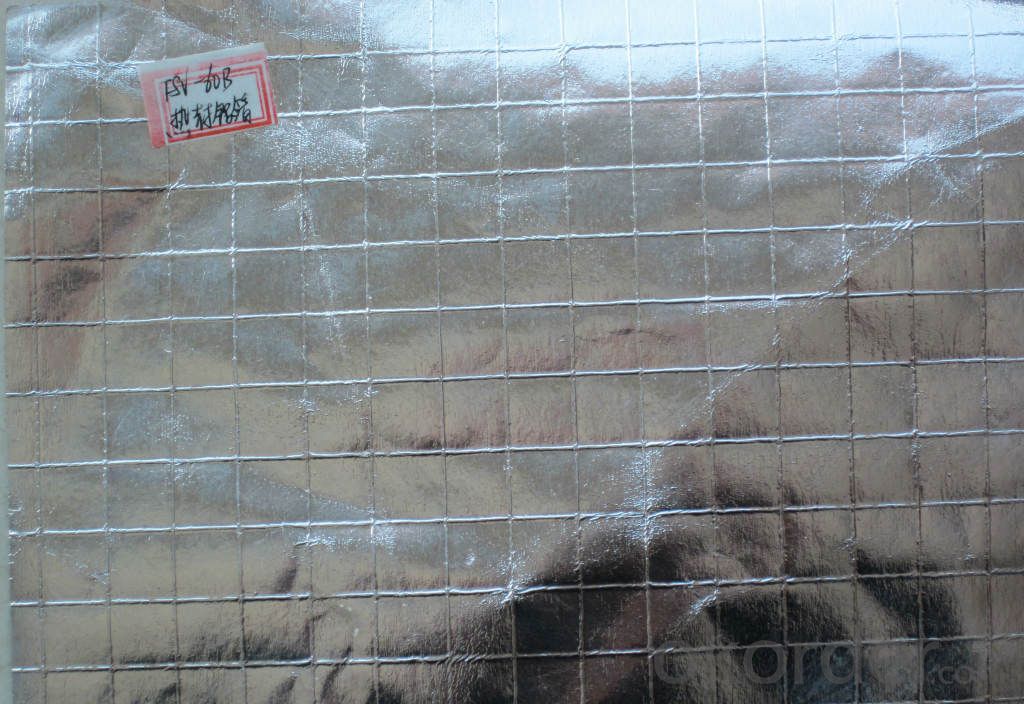

Aluminum foil tapes with heat sealing films

Aluminum foil tapes with heat sealing films

CODE | Acrylic Adhesive | Category | Thickness | Initial Stickiness | 180°Peeling Strength | Permanent Adhesion | Tensile Strength | Polyurethane Foam Adhesive Rate |

BLAMT-301 | Water-Based | Bopp | ≥0.07mm | ≥15# | 4n/cm | ≥24h | ≥25n/cm | |

BLAMT-302 | Oily | Bopp | ≥0.07mm | ≥15# | 6n/cm | ≥24h | ≥25n/cm | |

BLAMT-303 | Oily | Pe | ≥0.07mm | 7.5n/cm | ≥24h | ≥25n/cm | ≥60% | |

BLAMT-304 | Oily | Bopp | ≥0.07mm | 7.5n/cm | ≥24h | ≥25n/cm | ≥60% |

Aluminum foil coated adhesive tape

Composition and characteristics:

with aluminum foil as the base material, the back of the base material is coated with a layer of polypropylene (BOPP) or polyethylene (PE) film and coated with special release agent, and the front face is coated with factice or glue.

Main usage:

applied for encapsulating and winding evaporation pipelines for refrigerator, freezer and other refrigeration equipment, this tape has outstanding sealing and heat preservation performance, and it is easy and convenient to operate. The back of the products 303 and 304 is applied with special release agent and then they can be connected with polyurethane foam, so the heat sealing performance is more outstanding.

The above parameters are for reference only,

and special requirements can be applicable according to actual demands of users

- Q:I want to make a part using molten aluminum with a hole through the middle and would like to use a steel rod to do this. Would the bar stick to the aluminum when it cools and not be able to be removed? If so is there so type of coating I can use so it can be removed?

- Aluminium and iron are pretty incompatible materials, they don't form an alloy I don't think, so it is unlikely they would stick. Also, both metals will get an oxide layer on the surface which should keep them separate. Try it! If the finished part does stick, try heating the aluminium then dip the steel rod in some ice water.

- Q:Are 101 aluminum sheets magnetic?

- No, 101 aluminum sheets are not magnetic as aluminum is a non-magnetic metal.

- Q:What are the common applications of aluminum sheets?

- Aluminum sheets find widespread use in various industries, offering a multitude of applications. Within the construction industry, they are highly utilized for roofing, siding, and facades due to their lightweight nature, resistance to corrosion, and durability. The transportation industry also heavily relies on aluminum sheets, particularly for the production of vehicles and aircraft. Their exceptional strength-to-weight ratio makes them perfect for constructing car bodies, truck beds, and airplane components. Moreover, aluminum sheets play a significant role in the packaging industry, where they are employed in the creation of cans, foils, and closures. The remarkable thermal and electrical conductivity of aluminum also positions it as a popular choice for heat sinks, electrical enclosures, and electronic parts. Additionally, the marine industry benefits from the use of aluminum sheets in boat building, while appliances like refrigerators and cookware also incorporate aluminum in their manufacturing process. Ultimately, the versatility and advantageous properties of aluminum sheets establish their indispensability across various sectors.

- Q:Does Aluminum Foil really work to help beat the summer heat?I live in San Diego which is known for having perfect weather pretty much all year round, but just yesterday we are starting to get some record breaking heat. Most apartments, condos, and houses do not have A/C because like I just mentioned it's usually in the high 60s or low 70s during the spring and summer, perfect.Will Aluminum Foil work or can someone else suggest anything else?!PLEASE note that I'm just putting aluminum foil on my bedroom window which just faces some other apartment complex and I am not concerned with the aesthetics. I might consider putting something up (but just not sure what) on the living room window other than aluminum foil since everyone can see that window.

- Realize that foil is a conductor of heat. Your best action would be to open the top 1/4 of your window and also the bottom 1/4 of the window . This would get convection rolling, or a cooling breeze going, even if you are closed in, even in a ventilation column. Use sun blocking shades in the hot early morning sun and the hot evening west sun. Use the open on the top- open on the bottom- window idea to create the loss of heat - even moreso than a fan... which creates heat! Try using a room partition such as a pretty 3-fold dressing screen to stop the blazing sun from heating your space. It is a moveable shade screen to be used for your advantage.Stay cool Babe!

- Q:Can aluminum sheet be bent or formed into different shapes?

- Yes, aluminum sheet can be easily bent or formed into different shapes. Aluminum is a highly malleable metal, which means it can be easily bent, shaped, or formed without cracking or breaking. This property makes it an ideal choice for various applications where flexibility and customization are required. Aluminum sheets can be bent using various methods, such as using a brake press, roll forming, or by hand using specialized bending tools. The level of bendability may vary depending on the thickness and grade of the aluminum sheet, but in general, aluminum is known for its excellent formability and ability to be shaped into different configurations.

- Q:How to clean the engine oil and kerosene on the surface of aluminum sheet?

- you can buy a bottle of petroleum ether in chemical raw material shop, it will be clean after rubbing, or you can buy solvent oil.

- Q:Can aluminum sheets be used for reflective surfaces?

- Yes, aluminum sheets can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it an excellent material for creating reflective surfaces. Due to its smooth and highly polished finish, aluminum sheets can effectively reflect light, heat, and other forms of radiation. This property makes them suitable for a wide range of applications, including solar panels, mirrors, lamp reflectors, and reflective insulation. The use of aluminum sheets as reflective surfaces is advantageous due to their durability, lightweight nature, and resistance to corrosion.

- Q:Are the aluminum sheets suitable for manufacturing food processing equipment?

- Yes, aluminum sheets are suitable for manufacturing food processing equipment. Aluminum is a highly versatile and durable material that is known for its corrosion resistance, lightweight nature, and ability to withstand high temperatures. These qualities make it ideal for use in the food processing industry, as it ensures the equipment is hygienic, easy to clean, and can withstand the demanding conditions of food production.

- Q:I'm was thinking of buying an aluminium bike but I saw some good bikes with hi-ten.

- Get an aluminum frame Hi-ten steel is the buzz word for cheap plain steel.

- Q:Can aluminum sheets be used for protective enclosures?

- Yes, aluminum sheets can be used for protective enclosures. Aluminum is a versatile and lightweight material that offers excellent durability and corrosion resistance. It can be easily fabricated into various shapes and sizes, making it suitable for constructing protective enclosures for a wide range of applications. Aluminum enclosures are commonly used in industries such as electronics, telecommunications, aerospace, and automotive. They provide protection against environmental elements, such as moisture, dust, and electromagnetic interference. Additionally, aluminum enclosures can be further enhanced with coatings or insulation materials to meet specific requirements for thermal insulation, fire resistance, or electrical conductivity. Overall, aluminum sheets are a reliable choice for protective enclosures due to their strength, versatility, and ability to withstand harsh conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum foil tapes with heat sealing films

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords