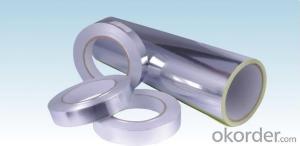

Aluminum Foil Tape T-F3001FR HVAC insulation Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

1) High tensile strength aluminum foil made from special aluminum

alloy, coated with aggressive solvent-based acrylic adhesive,

which provides high peel adhesion and quick sticking

2) Designed for sealing joints and seams of foil jacketing in

air-conditioning duct work

3)Excellent Peel Adhesion

4)Good Initial Tack & Permanent Bonding

5)Good Water & Fire Resistance

6)Outstanding Temperature & Aging Resistance

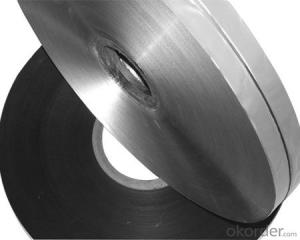

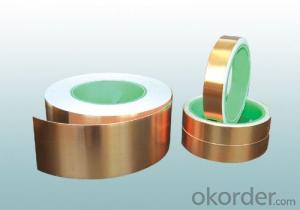

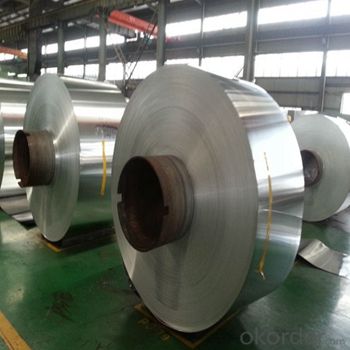

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

1) Foil thickness: 18, 22, 26μ

2) Roll width: 48, 50, 60, 72, 75, 96, 100mm

3) Roll length: 27, 30, 45, 50m

4) Log roll: 1.2 x 45m, 1.2 x 50m

5) Jumbo roll: 1.2 x 1200m, 1.2 x 1000m

5.FAQ

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: Cut Roll: ±0.3m, Jumbo Roll ±0.5%.

3. The product should be stored at room temperature and kept from wet and heat source.Shelf life: One year from shipment date when stored at 21°C (70°F) / 50% relative humidity out of direct sunlight.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q:My wife and I got married in HonoluluI am avid amateur cook and I simply fell in love with Hawaiian cuisineWe stayed at the Turtle bay resort and we were eating at the Surfer bar in the resort one night and I ordered a cheeseburger but I had not noticed that it said on Taro bunsI took a bite and it was delicious and then I noticed that the bread was purpleI asked the waitress but all she could tell me is that it was taro breadNow I know that food coloring is used to get a deeper purpleMy question is, does anyone know the recipe for taro hamburger buns, taro rolls, or taro sandwhich bread that is not filled with poi?

- A pretty ghetto but effective thing to do is iron it outUsing your clothing iron.

- Q:My friend put an icecream cookie wrapped in aluminum in the microwave for 6 seconds and for the first second it sparked up and there was smoke.Is that safe? should she eat it right this secon, right now? is there radiation?

- The aluminum wrapper absorbed all the energy, got hot, emitted sparks and probably started the paper the aluminum was bonded to on fire The food inside did not see any of the energyThe food is safe to eat.

- Q:Ionic and Covalent Bonding?

- search gourmet magazine on google and you will find much better recipies than brown rice!!

- Q:I want to store simple things in ziplocs, but don't want to use the non-recyclable regular type that end up in landfills and don't decomposeAny leads on products similar to what I'm looking for would be appreciatedBiodegradable plastic ziploc type bags.

- I just gave this recipe to someone else.but it's worth mentioning again.they're awesome!! SPICY CHICKEN WINGS.serves 12 Ingredients 1 cup soy sauce 1/2 cup vegetable oil 2 packets fajita or taco seasoning 4 lbs chicken wings 1In a bowl, combine your soy sauce, vegetable oil, and fajita packets and mix well2Divide your chicken wings into two batches and place each in a large zip lock bagPour half of your marinade over the chicken in each bag and place in the refrigerator to marinate for 4 hours, or over night3Preheat oven to 375 ? F 4Cover a baking sheet with aluminum foil, and spread your wings on the sheet in an even layerBake wings for 30-35 minutes and enjoy(Check for doneness in case it needs more time).

- Q:I purchased 2 round Wilton cake pansI washed them once in the dishwasher and when it was done, they both came out fadedThey are no longer shiny and are extremely dullI was under the impression they were dishwasher safeDoes anyone know why they did this? And if there is any way to get them back to their original condition? Thanks for your help!

- Ok I know you're probably not asking for scenes from the movie, but I got to throw this in there I LOVE the pencil trick scene in The Dark Knightlol XD

- Q:How do things get freezer burnt?

- Since people have already answered what freezer burn really is here's how you prevent it from happening to your foodFirst off no matter what you do your freezer should be set to its coldest settingThe temperature should be below 0 degrees FThis will freeze the liquid in the food quicker resulting in smaller ice crystal which results in less shredding of the internal cells of the foodDon't worry about the electricity it doesn't take all that much more to keep it at the lower temperature and its worth it1Use vacuum sealed freezer bagsI believe Ziploc has just come out with a cheap version 2If you don't want to do that then wrap whatever your are freezing (even if it is already in its own packaging) in 2 layers of aluminum foil and then put in a standard zip freezer bagLeave a small corner of the bag open and suck the air out with your lips and seal itDon't forget to label it since the foil prevents you from seeing the food.

- Q:I have a 2 3/8quot; aluminum round rodI want to drill a 6mm hole or bore through the rodThe bore must be perfectly centeredI do not have a lathe, but if it's the only way, do they sell them (lathes to work with metal) at Lowe's or Home Depot?

- Well aluminum is atleast easier to work with but if perfectly centered is required you would be better off paying a professional but if really close will work, then you got optionsFirst you will need a drill press if not then very carefully with a hand drill, secondly and most important is a vise that will not allow any movement of your stockalways center punch your hole and start small to allow for any errorIf your real motivated you can always build a brace for your drill to keep you striaght out of 2x4's.

- Q:why does Aluminum have the properties it has???as much information as possible please10 points thankoo

- A silvery and ductile member of the poor metal group of elements, aluminum is found primarily as the ore bauxite and is remarkable for its resistance to oxidation (aluminum is actually almost always already oxidized, but is usable in this form unlike most metals), its strength, and its light weight. Aluminum is used in many industries to make millions of different products and is very important to the world economy. Structural components made from aluminum are vital to the aerospace industry and very important in other areas of transportation and building in which light weight, durability, and strength are needed. The use of aluminum exceed that of any other metal except iron. Pure aluminum easily forms alloys with many elements such as copper, zinc, magnesium, manganese and silicon. Nearly all modern mirrors are made using a thin reflective coating of aluminum on the back surface of a sheet of float glass. Telescope mirrors are also coated with a thin layer of aluminum. Other applications are electrical transmission lines, and packaging (cans, foil, etc.). Because of its high conductivity and relatively low price compared to copper, aluminum was introduced for household electrical wiring to a large degree in the US in the 1960s. Unfortunately problems on the functioning were caused by its greater coefficient of thermal expansion and its tendency to creep under steady sustained pressure, both eventually causing loosening the connection; galvanic corrosion increasing the electrical resistance. The most recent development in aluminum technology is the production of aluminum foam by adding to the molten metal a compound (a metal hybrid), which releases hydrogen gas. The molten aluminum has to he thickened before this is done and this is achieved by adding aluminum oxide or silicon carbide fibers. The result is a solid foam which is used in traffic tunnels and in space shuttle.

- Q:Apart from aluminium and mercury, what else is in vaccines that shouldn't be?

- The biggest thing that comes out at me in this is 'jump off to get the treat'Dogs, especially the young and the elderly, should NEVER be allowed to jump off furnitureIt's way too easy to do damage to, in the case of your young Labimmature joints and muscle tone, and in the case of the elderly, old bones and jointsIf need be, keep him away from the couch completely, especially when you are not thereHe's looking on what you are attempting to do as a huge gameJust tell him No! and mean it, and help him off so he doesn't leap off and hit the groundFor no hairs on the sofa - use throws, like we all do LOLWhen the couch is not in use, upend the cushions or even put a chair, seat down, on there - to break the habit.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Tape T-F3001FR HVAC insulation Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords