Aluminum Foil Tape Synthetic Rubber Based 25Micron High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

Synthetic Rubber Based Aluminum Foil Tape is of aluminum foil as the carrier, coating with solvent based acrylic, synthetic rubber-resin, or water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Synthetic Rubber Based Aluminum Foil Tape: widely used for seaming and jointing bonding of various vapor barriers, fixing thermal fin in refrigerators. Provide fast and permanent bond performance for vapor barrier against the moisture.

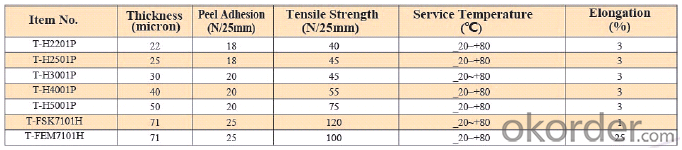

Typical Physical Reports of Synthetic Rubber Based Aluminum Foil Tape:

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1200mm; length according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Aluminum Foil Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q:Is packaging tape safe to use on leather?

- Packaging tape is not recommended for use on leather. While it may temporarily hold leather pieces together, using packaging tape can cause damage to the leather over time. The adhesive on packaging tape can leave behind residue that is difficult to remove and can stain or discolor the leather. Additionally, the strong adhesive can weaken the leather, leading to tears or permanent damage. It is best to use leather-specific adhesives or methods when working with leather to ensure its longevity and preservation.

- Q:Is packaging tape safe for use on delicate surfaces or materials?

- Packaging tape is generally not recommended for use on delicate surfaces or materials. It is designed to provide a strong and secure bond on sturdy surfaces such as cardboard boxes. Using packaging tape on delicate materials may cause damage, leave residue, or negatively affect the appearance of the surface. It is advisable to use specialized tapes or alternative methods to protect delicate surfaces during packaging.

- Q:Can packaging tape be used for shipping packages internationally?

- Yes, packaging tape can be used for shipping packages internationally. Packaging tape is designed to securely seal boxes and packages, ensuring that the contents remain intact during transit. It is commonly used for shipping both domestically and internationally. However, it is important to note that when shipping packages internationally, it is recommended to use packaging tape that meets the requirements of the shipping carrier and destination country. Different carriers and countries may have specific regulations regarding the type and strength of packaging tape that should be used. It is advisable to check with the shipping carrier or consult the destination country's customs regulations to ensure compliance with their guidelines. Additionally, it is always a good idea to reinforce the package with multiple layers of tape to provide extra security during international shipping.

- Q:Does packaging tape have a specific shelf life?

- Yes, packaging tape does have a specific shelf life. The shelf life of packaging tape typically depends on the type and quality of the tape. However, most packaging tapes have a shelf life of around 1 to 2 years if stored properly in a cool, dry place. It is always recommended to check the manufacturer's guidelines for specific information on the shelf life of a particular packaging tape.

- Q:Can packaging tape be used for sealing packages with confidential or sensitive contents?

- Packaging tape can be used for sealing packages with confidential or sensitive contents, but it is not the most secure option. For enhanced security, it is advisable to consider using tamper-evident or tamper-resistant packaging solutions, such as security tape or specialized envelopes, to provide an additional layer of protection against unauthorized access or tampering.

- Q:Can packaging tape be used for sealing paper bags?

- Yes, packaging tape can be used for sealing paper bags. Packaging tape is designed to have strong adhesive properties that bond well with various surfaces, including paper. When applied properly, packaging tape can provide a secure and reliable seal for paper bags, keeping the contents inside protected and preventing them from falling out or being exposed to external elements. It is important to ensure that the surface of the paper bag is clean and dry before applying the tape for optimal adhesion.

- Q:Is packaging tape easy to tear by hand?

- Packaging tape is usually quite simple to tear by hand. Many packaging tapes have a serrated edge or perforation, enabling effortless tearing to achieve the desired length, eliminating the need for scissors or additional tools. This characteristic facilitates swift and convenient packaging and sealing of boxes or packages, without any complications. Nonetheless, it is crucial to acknowledge that the ease of tearing may differ based on the brand and quality of the packaging tape.

- Q:What are the alternatives to packaging tape?

- There are numerous options available for securing packages or boxes instead of using packaging tape. Some of the popular choices are as follows: 1. Duct Tape: Known for its durability and ability to adhere to different surfaces, duct tape is a robust adhesive tape that serves as a viable alternative to packaging tape. 2. Masking Tape: Unlike packaging tape, masking tape possesses a lower level of stickiness. It is commonly utilized in painting or crafting projects, but can also be employed for securing packages. 3. String or Twine: A package can be secured by wrapping string or twine around the box and tying it tightly. This method is often used for packages that do not require a strong adhesive. 4. Packaging Straps: Made from plastic or polyester, packaging straps can be tightly fastened around the box to ensure secure packaging. They provide a reliable and sturdy alternative to packaging tape. 5. Adhesive Glue: For smaller packages or envelopes, adhesive glue can be used instead of packaging tape. It is crucial to select a strong glue that will securely seal the package. 6. Paper or Kraft Tape: Water-activated paper or kraft tape is commonly employed for sealing packages. The adhesive is activated by wetting the tape, resulting in a strong and secure seal. 7. Zip Ties: Zip ties, which are plastic ties, are often used for securely fastening large or heavy packages by tightly encircling the box. To determine the most suitable alternative to packaging tape, it is vital to assess the specific requirements of the package, including its size, weight, and handling needs.

- Q:How does packaging tape perform in high-temperature conditions?

- Packaging tape typically performs well in high-temperature conditions as it is designed to withstand heat. The adhesive used in packaging tape is usually heat-resistant, ensuring that the tape remains securely bonded even at elevated temperatures. However, it is important to note that the performance may vary depending on the specific type and quality of packaging tape used.

- Q:What are the considerations for using packaging tape on glossy surfaces?

- When it comes to using packaging tape on glossy surfaces, it's important to keep a few key things in mind. First and foremost, the smoothness and slickness of the glossy surface can affect how well the tape sticks. The glossy finish creates a barrier that can make it difficult for the tape to adhere securely. That's why it's crucial to make sure the surface is clean and free from any dirt, oils, or residue that could prevent the tape from sticking properly. Choosing the right type of packaging tape is also important. Opting for a tape specifically designed for glossy surfaces, like high tack or acrylic adhesive tapes, can provide better adhesion and last longer. These tapes are specially formulated to stick well to smooth surfaces and create stronger bonds compared to regular packaging tape. It's also a good idea to test the tape on a small, inconspicuous area of the glossy surface before applying it everywhere. This will let you see how well the tape sticks and ensure that it doesn't leave any residue or damage the glossy finish when you remove it. Temperature and environmental conditions should also be taken into consideration. Extreme heat or cold can affect how well the tape performs on glossy surfaces. For example, high temperatures can cause the adhesive to soften, leading to the tape failing, while cold temperatures can make the tape more brittle and prone to peeling. Lastly, it's crucial to handle the glossy surface with care to avoid leaving fingerprints, smudges, or scratches that could detract from its appearance. Wearing gloves or using protective films can help prevent these issues. By keeping these factors in mind, you can enhance the effectiveness and reliability of packaging tape on glossy surfaces, ensuring that your packages are securely sealed without compromising the glossy finish's aesthetic appeal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Tape Synthetic Rubber Based 25Micron High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords