Aluminum Foil Laminated Cryogenic Insulation Paper for Vehicle Cylinder

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Foil Laminated Cryogenic Insulation Paper for Vehicle Cylinder

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Application: | high-vacuum multilayer thermal insulation | Surface Treatment: | raw material or customer customized | Dimensions: | z paper |

| color: | white |

Packaging & Delivery

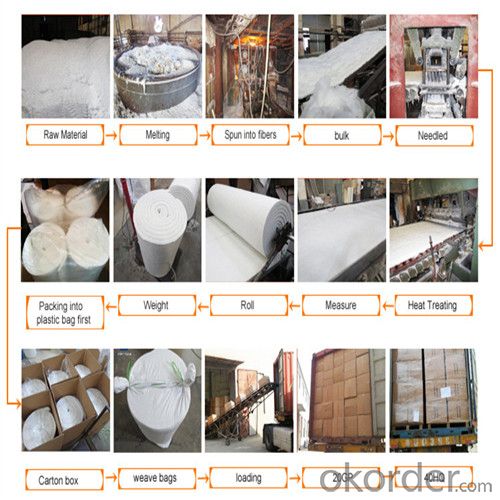

| Packaging Details: | by rolls,export normal packing with plastic bag and carton box |

| Delivery Detail: | 7-15 Days |

Specifications

Aluminum Foil Laminated Cryogenic Insulation Paper

1.light weight

2.good uniformity

3.low thermal conductivity

Insulation Blanket:

Cryogenic insulation paper/radiation shield compositions:

Cryogenic insulation paper(P paper/Z paper)/aluminum foil(or aluminized polyester film) compositions are laminated of Cryogenic insulation paper and aluminum foil(or aluminized polyester film).These products can be wrapped to the cryogenic inner tank directly and no need to composite by user. Therefore ,it can effectively reduce the waste of material and hugely increases efficiency. The width varies from 40mm to 1800mm.

Specification

| technical specification | aluminum foil | aluminized polyester film |

| condition | anneal | vcauum aluminizing |

| Thickness | 0.0065 | 0.012 |

| surface oiliness | without oil, not less than calss B on brush water test | No oil |

| Harmful Element(%) | Pb<0.01 Cd<0.01 As<0.01< span=""> | / |

| Width | 30-1780 | 30-1780 |

Our production

Our honour

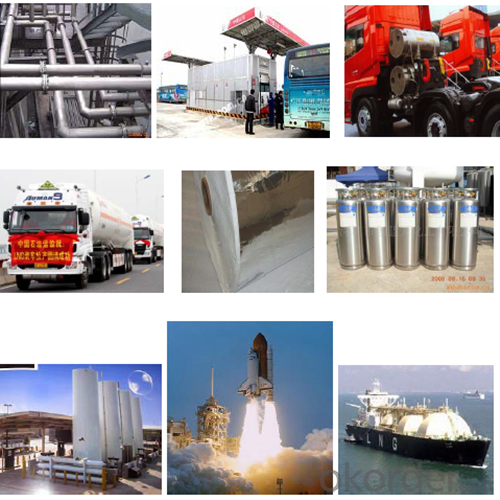

Application

Sample is on your request!

Welcome to visit our factory!

- Q:What is a cryogenic fast line

- Equipment is compressor, heat exchanger and expander (or throttle). The compressor and expander generally use a reciprocating or turbine. Commonly used heat exchanger coil type, shell and tube type or plate heat exchanger. Deep freezing technology, can the nature of the study of materials near absolute zero, and can be used for the separation of liquid and gas mixture of gases. Industry can get liquid oxygen, liquid, gas, etc.; Can be effectively separated from the air

- Q:Cryogenic treatment to improve what performance?

- To improve the hardness and strength of the workpiece;Ensure the dimensional accuracy of the workpiece;Improve the wear resistance of the workpiece;

- Q:How many changes in the properties of the cryogenic metal?

- 4 milling cutter milling hole surface Phi 12, 48-2NT5 milling cutter milling end 13, 48-2NT6 high speed steel twist drill drilling A3 of 129 2967 high speed steel twist drill drilling 40Cr of 146 3588 high speed steel 8 drill wear 25cr2NiMoV 10 hole 40 hole wear9 high speed steel 10 bit hour HT20-40 1235

- Q:I would like to ask how the process of cryogenic treatment

- The air is compressed to 0.5MPa, or 22.5MPa, can reduce the water cooling, after expansion machine (piston or turbine), the temperature dropped to close to the liquid temperature to the fractionation tower after liquefaction, become rich liquid, the liquid oxygen into a fractionating tower, liquid oxygen, nitrogen is directly sent out after heat exchanger. Inlet air cooling.

- Q:What is the meaning of vacuum cooling in heat treatment

- Placed for a period of time, known as cryogenic treatment, under normal circumstances are usually treated with liquid nitrogen.

- Q:What is the meaning of deep frozen

- So people use frozen ways to preserve food. Generally in a very short period of time, such as half an hour, so that the need to freeze the food quickly reach the specified ultra-low temperature, such as -30 ~-40 C.

- Q:Can the cryogenic phase control the cooling rate?

- 2, the compressor refrigeration principle: the use of the suction pipe of refrigerant gas inhalation of low temperature and low pressure, through the operation of the motor drives the piston to compress it after high temperature and high pressure refrigerant gas discharge pipe to the exhaust, to provide power for the refrigeration cycle, so as to realize the compression, condensation, expansion and evaporation (endothermic) refrigeration cycle. The refrigerant of the compressor can be repeatedly used for a plurality of times, the consumption is relatively small, the power consumption in the refrigeration process is more, the cooling rate is relatively small, and the refrigeration temperature range is 0-80 DEG C. The above mentioned two kinds of refrigeration in the process of industrial production of cryogenic box, the use of liquid nitrogen refrigeration will be more. Liquid nitrogen refrigeration can be used in the temperature range from 0 DEG C to -196 DEG C. []

- Q:What is the meaning of cryogenic technology in the mechanical process, what is the specific practice?

- Treatment of -130 DEG C is said to be a new and strong treatment process of cryogenic treatment to improve the wear resistance and toughness of materials and to improve the overall service life

- Q:Ultra low pressure casting mold useful, how to arrange the process? Thank you

- Cryogenic treatment in the connector industry and plastic mold industry has a large number of applications, connectors and plastic products industry production temperature is not high, about 300 degrees! Thus the mold in the production of hot and cold alternating stress is less, after doing a cryogenic treatment, the role of the stability of the size of the more obvious, tube time is longer!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Laminated Cryogenic Insulation Paper for Vehicle Cylinder

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords