Aluminum Foil Hot Rolled Checkered Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminum Foil Hot Rolled Checkered Steel Plate:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of Aluminum Foil Hot Rolled Checkered Steel Plate

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

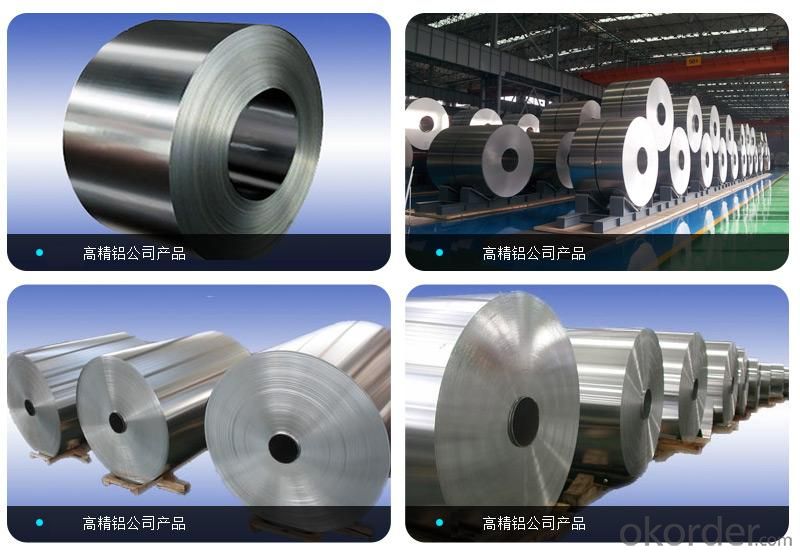

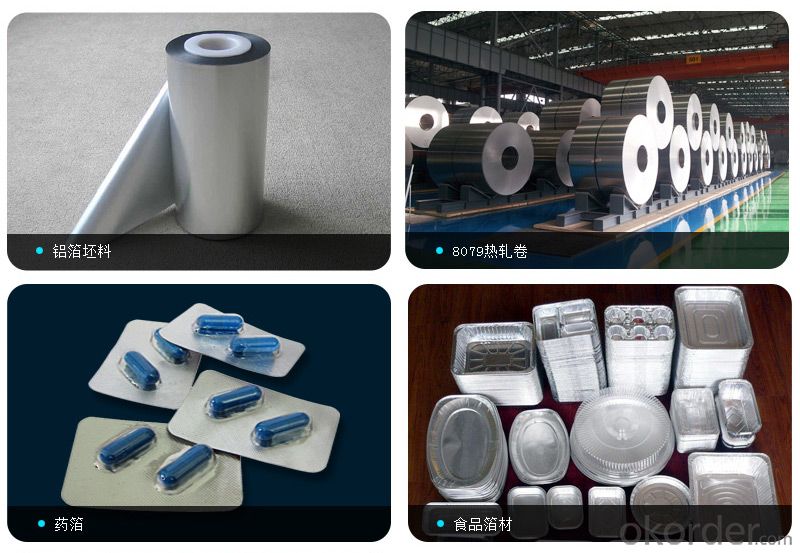

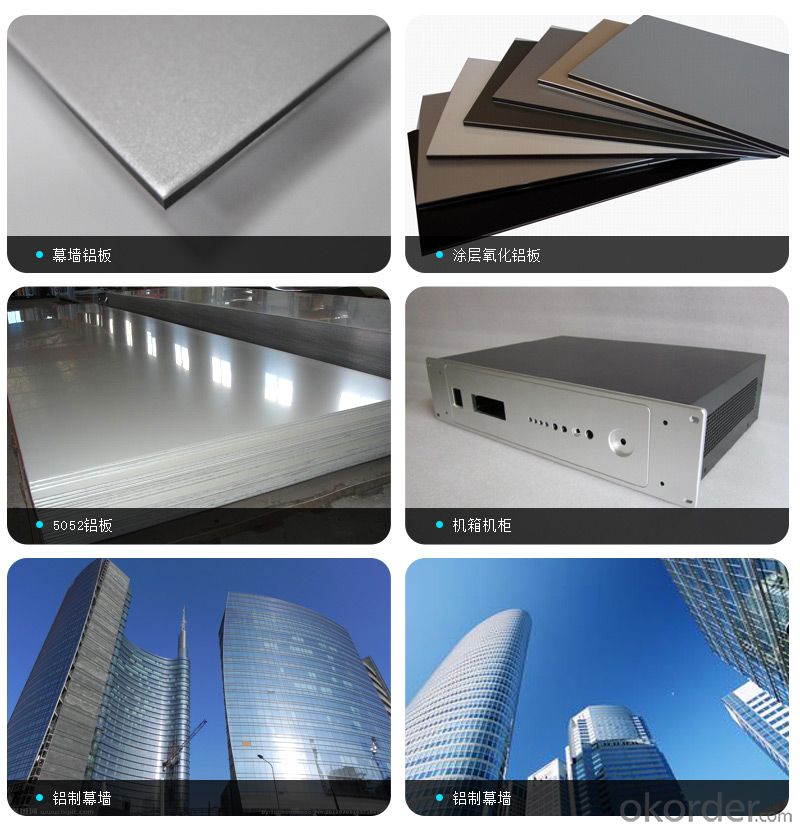

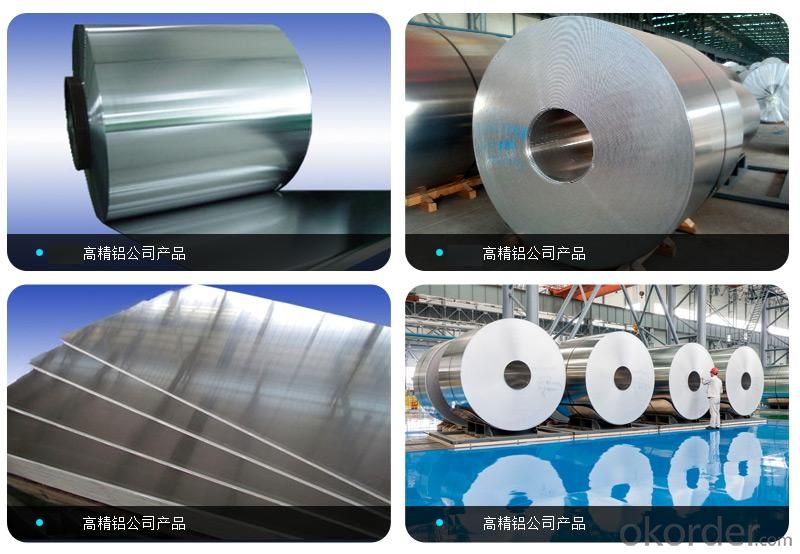

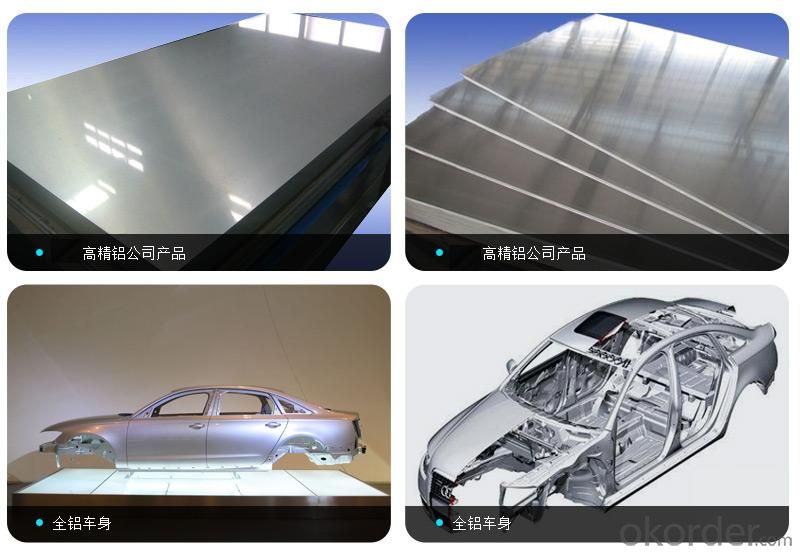

Images of the Aluminum Foil Hot Rolled Checkered Steel Plate:

Aluminum Foil Hot Rolled Checkered Steel Plate Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

Production Aluminum Foil Hot Rolled Checkered Steel Plate:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

- Q:If a mirror has a diameter of 10.240 cm and you want to have a coating that is 0.0250 mm thick of Aluminum on it, how many grams of aluminum will you need? How many atoms of aluminum are in the coating? The density of aluminum is 2.702 g/cm^3You may consider the deposited aluminum to be a cylinder from which the volume can be determined using the equation for the volume of a cylinderThanks!

- 0.0250 mm thick equals 0.00250 cm thick volume (surface area) (thickness) volume (pi r^2) (thickness) volume (3.14) (5.12cm)^2 (0.00250 cm) volume 0.20578 cm^3 find mass using density: 0.20578 cm^3 2.702 g/cm^3 0.5560 grams of Al your first answer, rounded to 3 sig figs is 0.556 grams of Al find moles, using molar mass 0.556 grams of Al 26.98 g/mol 0.020609 moles of Al using Avagadro's number, find atoms: 0.020609 moles of Al 6.022 e23 atoms / mole 1.241 e22 atoms your next answer , rounded to 3 sig figs is 1.24 X 10^22 atoms of Al p.s the answer is Magnesium to your question: A 0.98338 gram sample of a metal (II) carbonate containing an unknown metal M, was heated to give the metal (II) oxide 0.5133 grams of CO2What is the metal? use molar mass to find moles: 0.5133 grams of CO2 44.01 g/mol 0.01166 moles of CO2 by the equation: 1 MCO3 - 1 MO 1 CO2 0.01166 moles of CO2 was produced from an equal 0.01166 moles of MO find molar mass of MCO3 0.98338 gram sample / 0.01166 moles of MO 84.34 g/mole subtract the molar mass of (CO3) 60 g/mol gives the molar mass of the metal as 24 g/mol that's Magnesium

- Q:Who was the scientist who invented frozen foods?

- You can also coat the bacon in chocolate after you fry it!!!!

- Q:Help! I'm making cupcakes for my son's class and we only had 16 baking cups, we need 24.all the stores are closed, is there another way i can make them? Like if i crisco the bottom of the pan or something? 10 points best answer!

- Vegetables have fiber- Broccoli, spinach, beans Bread has fiberI know bananas have fiber but not how much

- Q:the structure of an A1 atom using the following terms, protons, neutrons, electrons, ionization energy, engry levels, atomic mass, and isotopes.

- The unit is too small for the houseEfficiency is in relation to fuel used to BTUs, not that less BTU will heat the same as moreMe thinks you got taken.

- Q:tooth paste dont work i cant buy silver polisher no money what can i do how do i polish it with stuff i would have around the house?

- Well, not IN the fridge, but I have been away from home for 3 weeks - am still away - and I left some bananas in a bowl on top of the fridgeThey were pretty brown when I left, so I suspect they will give me a nice warm hug when I get home tomorrow :O

- Q:the only real differences i know of are that the M3 is made of steel opposed to the oh so flammable aluminum of the M2 and that it doesn't have those useless firing ports, anybody care to explain in detail the differences?

- The hulls of the two vehicles are absolutley identical in every single wayBoth are aluminum (which is not oh-so flammable) with steel laminate armorLevels of protection are the sameThe only differences are internalThe current M2A2 is an Infantry fighting Vehicle designed to transport most of an infantry squad on the battlefield so has seats for 6 dismount soldiers plus its crew of 3It has no firing portsThe M3 is a Cavalry Fighting VehicleIt carries just 2 scouts instead of 6 infantry so the extra space is used to carry more ammunition: an extra 5 TOW missiles, 600 rounds of 25mm and 2,000 rounds of 7.62mm to be preciseIt was also intended to carry a motorcycle but this was never done.

- Q:So I want to make a glazed ham with pineapple and brown sugar.NOT CLOVESWhat else could I mix the brown sugar and honey with?.anything or is that good?Do I put the glaze on right away or after a certain amount of cooking time.Do I put the pineapple rings on right away or after a certai amont of cooking time.I have a 7 pound ham, and it will take about 2 1/2 hoursTHANKS

- Basically, they are requiring for you to write a report on Asset classificationList different type of assets in their categories keeping in mind the fixed assets, depreciating assets etcKeep liquidation of assets in mind as you do detail your report grouping the assets in the format described aboveHope this helps!

- Q:so i made a small water bong and i need something that will pack a fat bowl but without the nugs able to fall threw, i looked and i dont have a lot of things to use, what are so good ones though just in case im not thinking of the right stuff to use?

- Steal the screen out of the aerieator on the kitchen fawcet, and use aluminum foil for the sides of the bowl, wrap carefully and make sure the screen is securely wedged in at the bottomI don't know what you're using for the tube, so you can probably just have the foil extend below the screen an inch or so and crimp tape it to the tubePossibly the bottom part of the shell of a light socket would make a good bowl, (cut a circle of window screen slightly bigger than diameter of socket and wedge it inLeave some space under it (don't shove it completely to the bottomThe thread will fit 1/8 water pipe (same as the tubing that goes down the center of a tablelamp).

- Q:I'm really stumped on this question, any help would greatly be appreciated!The aluminum foil on a roll has a total area of 25m^2 and a mass of 1496 gUsing a density of 2.7g/cm^3 for aluminum, determine the thickness in millimeters of the aluminum foil.

- Given: Area: 25 m^2 Mass: 1496 g Density of aluminum: 2.7 g/cm^3 Want: thickness (in mm) Notice that you have three components that, if you cancel them out, will end up leaving you with a single dimension unit for thickness (in m or cm)First, either convert area to cm or density to g/m^3; I'm going to convert area to cm to match the units of density: (25 m^2) (100 cm / 1m)^2 - remember to square the whole conversion, not just the m part So 25 m^2 25 10000 cm^2/m^2 250,000 cm^2 (canceling the m^2 units) Now, we just manipulate the density by multiplying it by the given area and mass (which we use as conversion factors), canceling the units until we are left with only units of thickness, cm: (2.7 g/cm^3) (1 / 1496 g) (250000 cm^2) 451 / cm Reciprocate it to be 1/451 to get cm in the numerator 451 / cm 1/451 cm 0.0222 cm Convert cm to mm 0.00222 cm (10 mm / 1 cm) 0.0222 mm or 2.2210^-1 mm It's a pretty small number but it makes sense, because aluminum foil is very thinHope this helped :)

- Q:HeliumFluorineSiliconAluminumHydrogenArgonCalciumNitrogenSulfur

- For sure a barrier should be between the porch and the attic and more insulation will helpRolls of fiberglass insulation can be purchased at most of the big box stores in your areaIt is easy for a homeowner to install with a staple gun and some gloves and coveralls to keep the glass out of your hair and clothing Since this is a Habitat home the work was done by volunteers who are trying to help Humanity have some better housing in their areaSometimes they make mistakes, sometimes they do not know everything that should be done for a home built by master craftsmenElectric heat is always expensive compared to natural gas but it is easier and less expensive to install Good luck to you in your new home.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Hot Rolled Checkered Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords