Aluminum Foil FSK insulation facing for Glasswool

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 210000 m.t.

- Supply Capability:

- 50000000 m.t./month

- Option:

- 4ft*8ft

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

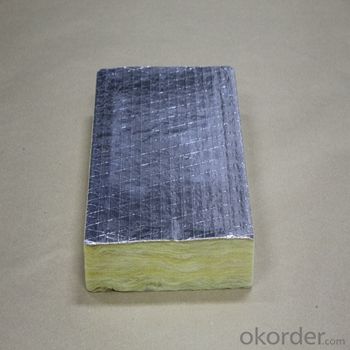

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination Glasswool.

2.Main Features of the Aluminum foil facing:

• Light weight

• Small inertia resistance

• High manufacturing accuracy

• Strong heat dissipation ability

• Good visual effect

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

- Q:Can mineral wool, rock wool and glass wool thermal insulation be applied to inverted roofs?

- It can be applied and it is just a problem of construction. Some are easier in construction and some are difficult.

- Q:What are the differences among glass wool, rock wool and mineral wool?

- So performances are the same. Though materials are different, they are the same as glass wool. They are blown into wool after being melted. Rocks and slags are raw materials, and they will mix together in the same proportion, and finally become glass.

- Q:What's the difference between rock wool board, glass wool board, glass wool felt?

- First question: These three products are used for thermal insulation in roof and wall surface, ship, equipment respectively. Second question: specifications: Rock wool board: 1000 * 630 1000 * 600 1200 * 6001200 * 630 Density is 60-100KG / M3. Imported and exported density is 60-100KG / M3. Glass wool board: 1200 * 600 density: 20-40KG / M3 Glass wool felt : width:1200 density:10-30 [For exoprt] Third question: They can all reach Class A non-combustible. Fourth question: Rock wool board is waterproof and fireproof while glass wool is only fireproof. Fifth question: They can all use tinfoil. Glass wool felt needs to be vacuumized because it has low density. [These are what customers need. ] Sixth question: Add me, and I will inform you the latest changes. Seventh question: It can be used in other ways. Contact me for pecific price.

- Q:who knows the construction technology of glass?wool?board?

- Construction Technology of glass wool board is very refined, and it is more professional. apply one layer of dry laid asphalt → → wooden keel installation→ → install gypsum board glass wool blankets → Paste a layer of glass fiber cloth → → mounted on an aluminum mesh → → fixation of aluminum mesh. I think it is very commendable technique.

- Q:What are the raw materials of centrifugal glass wool?

- Although I see it every day, but I really do not know about it, I only know that the main materials include glass and lime.

- Q:Is centrifugal glass wool or rubber and plastic insualtion board better for air-conditioning air duct insualtion?

- Rubber and plastic insulation board is better.

- Q:Which is more suitable for industrial pipe insulation: glass wool or rock wool ?

- Glass wool, now rock wool seems to be out of date.

- Q:How much is the unit weight of thermal insulation glass?wool?boards at least? How much is the unit weight of sound absorption glass panels?

- Sound-absorbing boards must be more than 80K at least, we use boards of 96K.

- Q:What is the fire rating of fireproof sound-insulating glass wool board?

- Generally we do not use A1, A2 but A class, which is non-combustible levels. A level is higher than the B level. B-level is divided into B1and B2. B1 stands for flame retardant type and B2 combustible type. rock wool and glass wool both rates A class. secondly, Rockwool can endure high temperature of 800 degrees, glass wool 450 degrees.bulk density of rockwool is heavier than that of glass wool. And glass wool has better waterproof performance.

- Q:What are the standards of glass wool board?

- The national standard of rock wool board for exterior wall in construction is GB / T25975-2010, rock wool board for curtain walls in construction is GB / T25975-2005, and industrial rock wool board is GB / T11835-2007. The above-mentioned criteria are the standards of using rock wool products in various industries! Rock wool board is specifically designed and produced for exterior thermal insulation thin plastering system. It can be applied to the cosntruction of concrete or brick based buildings or thermal insulation or energy-saving of the exterior walls of he existing buildings; Wherein rock wool belt for thermal insulation of exterior walls can also serves as fire buffer zone and it can be used with thermal insulation material whose combustion performance is below A level to improve the fireproof function of the exterior walls of the building.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil FSK insulation facing for Glasswool

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 210000 m.t.

- Supply Capability:

- 50000000 m.t./month

- Option:

- 4ft*8ft

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords