Aluminum Foil for Pharmaceutical Blister Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Description

Aluminum foil is widely used in medicine or pharmaceutical packaging, especially for Asian market. Because the good anti heat and anti wet specification, it's very good for packaging tablets and food. Noramlly for medicine packging, the quality should be higher than food packaging. For blister packaging, we usually use direct casting quality, and the popular alloy is 8011 with hard temper.

2.Specification and Application

Specification

| Alloy | 8011 |

| Temper | hard |

| Process | DC / CC |

| Thickness | 20mic~30mic |

| Width | 400mm~1500mm |

| Core ID | 76mm / 152mm |

Chemical Composition

| Alolly 8011 | % Maximum |

| Si | 0.05~0.13 |

| Fe | 0.7~1.3 |

| Cu | 0.05 |

| Mn | 0.02 |

| Mg | - |

| Cr | - |

| Ni | - |

| Zn | 0.1 |

| Ti | 0.02 |

| Zr | - |

| Others | 0.15 |

Property

| Tensile strength | 150~200Mpa |

| Elongation | 0.5%~3% |

| Bursting | / |

3. Advantages

We've been specialized in aluminium foil for more than ten years, we know this product very well, and we have good finacial support from government. Meanwhile, we can offer both DC and CC quality with this kind of 8011.

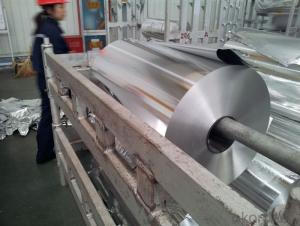

4. Pictures

5. FAQ

What is your Production?

Our regular production time is over 30~40 days, if it's regular size, the time can be shorter.

What is your MOQ?

The MOQ is 3 tons per size.

- Q:I dont have parchment paper to line the bottom of my cake pan, can i just use non-stick aluminum foil?

- Yea, you can but it won't be as prettyUse some crisco and smear it on really thin then sprinkle some flour on it and tap it aroundIt will work better than al foilFoil also will alter the baking time.

- Q:i have a party and i need a recipt for ilalian brd for about 50 people

- A little stiff should be fineIt means that there is enough oil inside of it to fiction correctlyTake a look at he fan clutchIf it is wet from oil, then you should be concernedIf not I would not worry about itDo this, with the engine warm, rev the engine while observing the fan, if it spins slowly, then you have problemIf it spins faster when reved then you probably OK.

- Q:How to fix holes in aluminum boatsPlease leave links in answer for extra details?

- Tight woven metal mesh,(you can get it at home depot) and weld it over the hole, then get yourself a small bucket of weatherproof roof cement(Also in home depot) Cement over the mesh, and there you go.

- Q:i have to make a home made hot dog cooker for science with a box a light bulb, 4 big paper clips, paint, aluminum foli it has to be in for 10 minutes so what is the best way to do it?

- Car, tv, mobile phone, calculator, in fact most objects that use electricity in some form or other would have some form of microprocessor embedded in them somewhere.

- Q:When I try to use the signal switch I get nothing.no noise no flashing inside or out.But when I check outside of the car all the lights come on as normal.

- Do your 4 way flashers (aka, hazard lights) work? If they do, the problem is in the switch, if they don't, its probably your flasherIts a aluminum tube shaped thing in your fuse box

- Q:I have this question and I don't know how to figure it out:Determine the number of protons, neutrons,and electrons in an atom of aluminum-27? any help please? or do you know how to figure this out?

- Al 27 in an isotopeIsotopes have the same number of protons, but different numbers of neutronsatomic number number of protons Aluminum's atomic number is 13 27 - 13 14 neutrons protons: 13 neutrons: 14 electrons: 13

- Q:I am doing a worksheet in Chemistry and need a bit of help.9Given quot;Xquot; could be any element determine the charge on 'X' given the following chemical formula: X3P31An atom that has 5 valence electrons would probably form an ion with what charge? Explain.366.02 E 23 is the number of particles in what? Why is this important? (I know the number is the amount of particles in a mole, but why is it important?)44How much aluminum chloride is produced when 10 g of aluminum reacts with 5 grams of chlorine? 2Al + 3Cl2 -gt; 2AlCl3Thanks!

- I saw a cool airplane in my Chemistry classIt was made out of coke cansIt was very cool.

- Q:okay, this is a reeally dumb science assignment, i need to make a procedure to preserve a pb and j sandwich i can use these materials: sheet of cardboard, string, straws, aluminum foil, plastic sandwich bag, sandwich, tasking tape, brown paper bagi really don't know anything about food preservation, so give me some tips please! what should i do./ make out of the materials i can use?????

- My mother used to make the sandwiches for the week then freeze themThey were thawed by lunchtime, no problem.

- Q:what is the meaning and usage of aluminium deep trough sheets?

- Coins are made of either nickel or copperThey are not worth their face value - eg, a 5p is not really worth 5p in scrap metal when melted downLike notes, they are only a promisory note to pay and exchangedHowever, there was a period eariler this year when the price of copper went up so much that the 2p was worth its face value.

- Q:Which of the following statements are true?Check all that apply AIndium (In) is bigger than aluminum (Al) BChlorine (Cl) reacts by losing electrons CSelenium (Se) is bigger than polonium (Po) DIodine (I) has five electron shells.

- The only statement that is true is D Iodine has 53 electrons occupying 5 shellsYou get this info from the fact that Iodine is in period 5 of the periodic table

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil for Pharmaceutical Blister Packaging

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords