Aluminum Foil Facing Resist High Temperature Reinforced

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 3000000 roll/month

- Option:

- Aluminum Foil Tape

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum Foil Facing Resist High Temperature Reinforced

Product Description

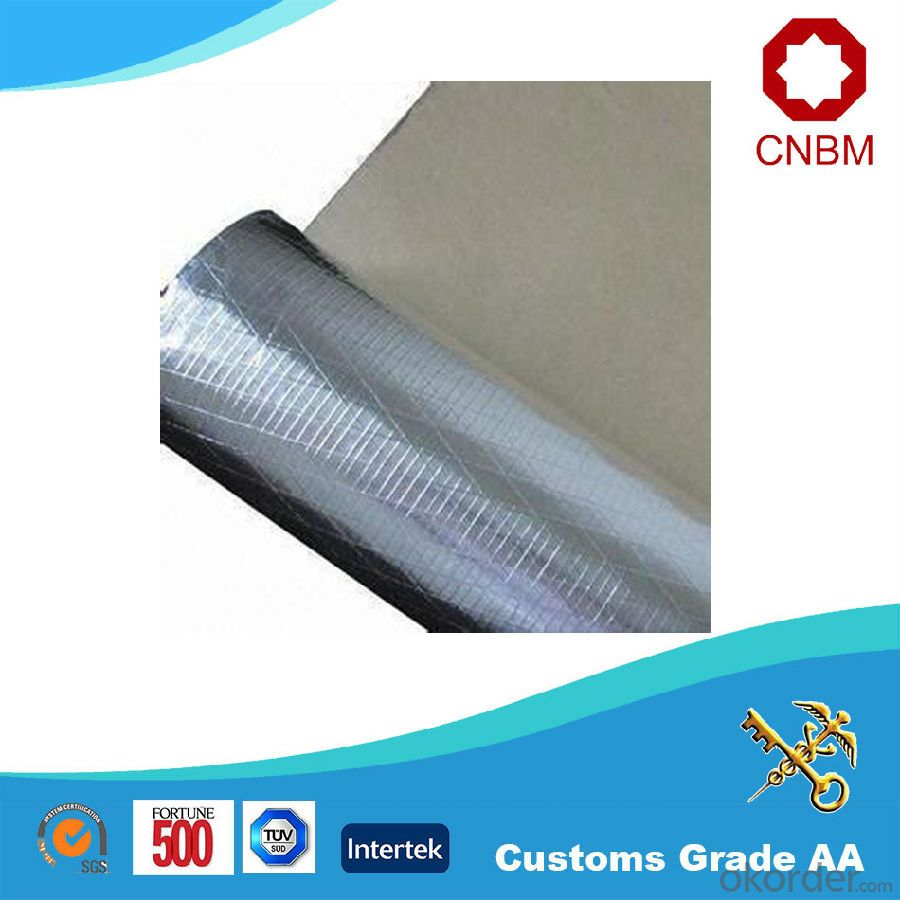

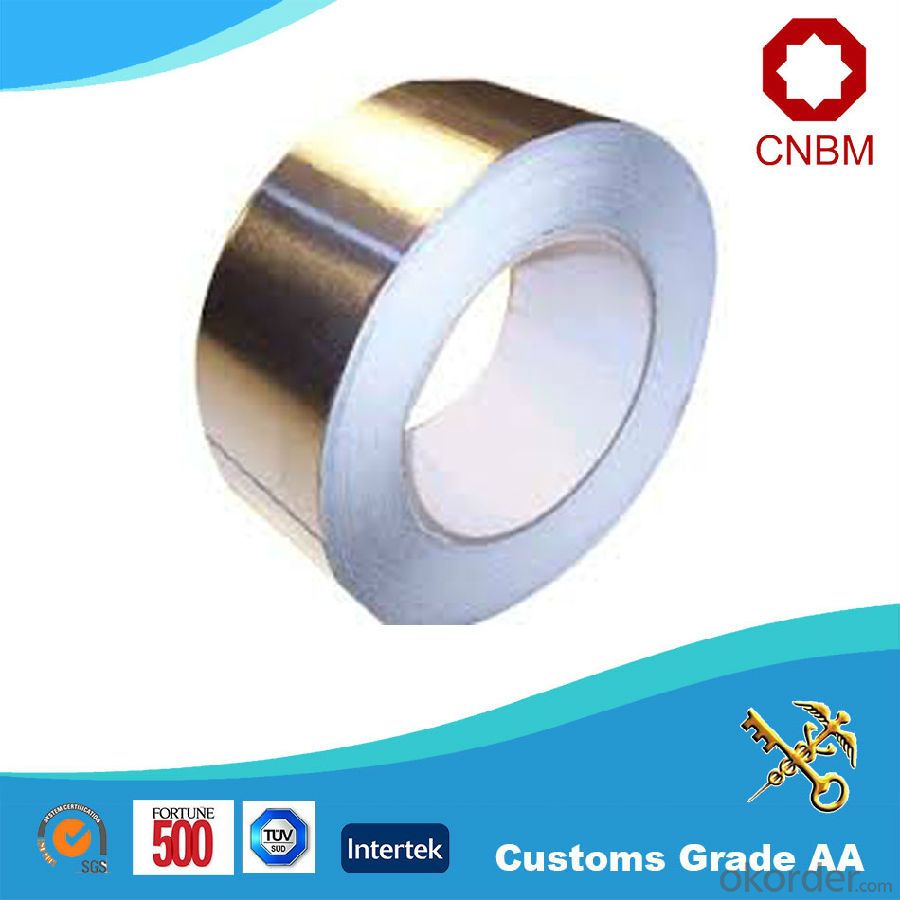

Aluminum Foil Tape is of aluminum foil as the carrier, coating with solvent based acrylic, synthetic rubber-resin, or water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

Features

Excellent adhension

Resistance to high temperature

Resistance to aging

Leave no residue

High mechanical strength and good impact resistance

Data Sheet

Item | Aluminum Foil Facing |

Thickness (micron) | 50 |

Peel Adhesion (N/25mm) | 16 |

Tensile Strength(N/25mm) | 35 |

Service Temperature (℃) | 60 |

Elongation (%) | 5 |

| Liner | White Release Paper |

Color | Silver |

Authorized Certificate

FAQ

1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

2. What are other tapes?

Cloth Tape: widely used for wrapping various material products etc.

PVC Tape: used for electrical application, floor marking and pipe wrapping.

3. How long can we send the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:What is the difference between acrylic and hot melt adhesive for packaging tape?

- The main difference between acrylic and hot melt adhesive for packaging tape lies in their composition and performance. Acrylic adhesive is made from water-based acrylic polymers and offers excellent clarity and UV resistance. It is ideal for long-term storage and can withstand temperature fluctuations. Hot melt adhesive, on the other hand, is a synthetic rubber-based adhesive that provides instant bonding and superior tack. It is suitable for applications requiring immediate adhesion and performs well in high-temperature environments. Overall, the choice between acrylic and hot melt adhesive depends on the specific packaging needs and conditions of use.

- Q:What's the problem of sealing the tape off?

- When the tape is pulled off, there are too many problems. I will answer the phone one day, and the tape will be broken. I said you will try another volume, or I will ask you to take a good look at the circumference of the tape

- Q:Does packaging tape have any specific certifications or standards?

- Yes, packaging tape can have specific certifications or standards. There are various organizations and standards that set guidelines for packaging materials, including packaging tape. One of the most common certifications for packaging tape is the International Organization for Standardization (ISO) certification. ISO sets standards for quality management systems, and packaging tape can be certified under ISO 9001:2015, which ensures that the product meets certain quality criteria. In addition to ISO certification, packaging tape can also adhere to specific industry standards such as ASTM International standards or European Union directives. ASTM International develops and publishes technical standards for a wide range of materials, including packaging tape. These standards ensure that the tape meets specific requirements related to strength, adhesion, and durability. Furthermore, some packaging tapes may have certifications related to their environmental impact. For example, certain tapes may be certified as recyclable, biodegradable, or made from sustainable materials. These certifications can be obtained from organizations like the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI), which promote responsible forestry practices. It is important to note that not all packaging tapes will have certifications or adhere to specific standards. However, if a packaging tape does have certifications or complies with certain standards, it signifies that the product meets certain quality, performance, or environmental criteria.

- Q:Food packaging, sealing tape printing and product manufacturers inconsistent with the use of it?

- This small detail is best not to careless, after all, some customers will pay attention to theseAdopt landlord,

- Q:Are there any specialty packaging tapes for specific applications?

- Yes, there are specialty packaging tapes available for specific applications. These tapes are designed to meet specific needs such as high strength, temperature resistance, moisture resistance, or delicate item protection. Examples include double-sided tapes, reinforced tapes, freezer tapes, and tamper-evident tapes. These specialty tapes offer enhanced performance and durability for specific packaging requirements.

- Q:What are the best practices for storing packaging tape rolls?

- The best practices for storing packaging tape rolls include: 1. Keep the tape rolls in a cool and dry environment: It is important to store packaging tape rolls away from direct sunlight and humidity. Extreme temperatures can cause the tape to become less effective and lose its adhesive properties. 2. Store the rolls upright: Storing the rolls upright helps maintain their shape and prevents them from getting squished or damaged. This also makes it easier to access and use the tape when needed. 3. Use a tape dispenser: Investing in a tape dispenser is a great practice for storing packaging tape rolls. Dispensers not only keep the rolls organized but also protect the tape from dust, dirt, and accidental damage. 4. Seal the rolls properly: Ensure that the tape rolls are securely sealed after use. This prevents dust and debris from accumulating on the adhesive side and maintains the tape's effectiveness for future use. 5. Keep an inventory of tape rolls: It is useful to keep track of how many tape rolls you have in stock and their respective sizes. This helps in planning and restocking when needed, avoiding any inconvenience or delays during packaging. 6. Avoid storing near chemicals or sharp objects: Packaging tape rolls should be kept away from any chemicals, solvents, or sharp objects that could potentially damage the tape or compromise its adhesive properties. By following these best practices, you can ensure that your packaging tape rolls remain in good condition and are readily available for use whenever needed.

- Q:Is packaging tape easy to tear by hand?

- Yes, packaging tape is generally easy to tear by hand. Most packaging tapes are designed with a serrated edge or perforation, making it easy to tear off a desired length without the need for scissors or any other tools. This feature allows for quick and convenient packaging and sealing of boxes or packages without any hassle. However, it is important to note that the ease of tearing may vary depending on the brand and quality of the packaging tape.

- Q:What are the common brands of packaging tape?

- Some common brands of packaging tape include Scotch, Duck, 3M, Gorilla, and Uline. These brands are well-known for their durability, adhesive strength, and ease of use. They offer a variety of options including clear, tan, and colored tapes, as well as different widths and lengths to suit various packaging needs. Additionally, these brands often provide options for different types of packaging materials such as cardboard boxes, plastic bags, and bubble wrap. It's important to choose a reputable brand when selecting packaging tape to ensure secure and reliable sealing of packages.

- Q:Can packaging tape be used for sealing plastic flower pots?

- Indeed, packaging tape is capable of effectively sealing plastic flower pots. This versatile adhesive tape is widely utilized for the purpose of sealing boxes and packages. Its robust adhesive properties render it suitable for securely fastening plastic flower pots, thereby preventing any potential leaks or spills. However, it is crucial to ensure that the surface of the plastic flower pot is devoid of dirt or moisture before applying the tape, as the presence of either could compromise its adhesion. Moreover, it is worth mentioning that there exist specialized tapes explicitly designed for sealing or repairing plastic materials, which may offer superior performance and durability when employed on plastic flower pots.

- Q:Can packaging tape be used for sealing packages with electronics or electrical components?

- Yes, packaging tape can be used for sealing packages with electronics or electrical components. However, it is important to note that not all packaging tapes are suitable for this purpose. When selecting a packaging tape for sealing packages with electronics or electrical components, it is recommended to choose an anti-static or ESD (electrostatic discharge) safe tape. These tapes are specifically designed to prevent static electricity from damaging sensitive electronic components during shipping or handling. Using regular packaging tape without anti-static properties may pose a risk of static discharge that could potentially damage the electronics or affect their performance. Therefore, it is crucial to consider the specific requirements of the electronics or electrical components being packaged and select an appropriate tape to ensure their protection.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Facing Resist High Temperature Reinforced

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 3000000 roll/month

- Option:

- Aluminum Foil Tape

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords