Aluminum Foil Facing Mylar for Bubble Heat Seal Composite Film and Fire-Retardant PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

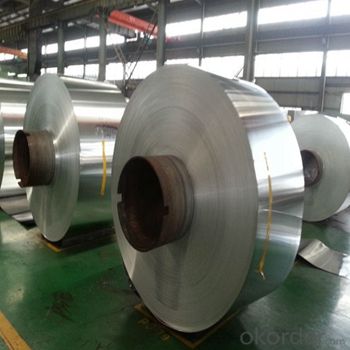

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

- Q:What are the uses, features and descriptions of PET protective films?

- Use of PET protective film1. surface hardening (HC) treatment, up to 3.5-4H, scratch resistant and wear-resistant.2. silicone composite layer is adhesive, can prevent the formation of bubbles.3., silicone features are repeated paste, leaving no traces, no corrosion of the surface.4, used to protect the LCD, touch screen, mobile phones, digital cameras and PDA screen, in use to avoid scratches, to protect the screen effect.5. the coating is made of an optical grade transparent polyester film (PET) coated with silica gel and then bonded to a transparent polyester (PET) release film.6., composite silicone layer can effectively absorb part of the direct collision, protect the screen is not easy to damage.

- Q:How to remove the protective film on stainless steel elevator?

- Blow the film with electric hair dryer at first. And then carefully tear it off.

- Q:How to remove the protective film on painted iron plate without damaging the paint? The film is very thin.

- Sticking wide adhesive tape to the film and pull the tape to tear off the film.

- Q:What is the explosion-proof tempered glass protective film?

- There's no such film. Anti-explosion and tempered means to apply glue to two or more pieces of original glass after they are tempered. And pressing these tempered glass using PVB film at high temperature to make them sticked to each other. In this way, the glass won't fall off because of the glue when the glass is broken. This is what anti-explosion means. In fact, protective film is just a layer of transparent plastic film that is about 0.38mm thick.It's okay to use a single piece of it. But there's no need to use it on glass. If you insist on using it, the money you spend will double or increase more.

- Q:Excuse me, what reason is mobile phone protection film stuck to mobile phone screen protect film to be able to bubble?

- There are two kinds of foaming reasons, one is in the air, there are two dust wipe clean, this is all right, the first time I posted OK8 film too, thought is broken, fortunately have posted against the instruction above, teach me how to do, okay, squeezed out is, do not use nail squeeze film will bad ~ Cabu out a card package,

- Q:How to remove the protective films on ceramic tiles?

- There are three types of protective film used on ceramic tiles: The first one is plastic thin film which can be slowly torn by hands or gently rubbed off with steel wool; The second is anti-fouling protective film which can be wipe off using towel with white cement; The third is wax protective film which can be wipe off with dry towel with electric diluent, lacquer thinner, talcum powder or white cement.

- Q:Protective film treatment method for aluminium alloy door and window

- Under normal circumstances, after installing the wall, the exterior wall should be ripped off immediately after the protective film.

- Q:The introduction of protective film used on flooring finish.

- The life of the knit cotton paved on the floor is much longer than that of other similar products. The product is mainly used by decoration company during construction. It has function of shock absorption. It does not only enhance the tanacity of the product but also increase the resilience and flexibility of it to a large extent at the same time.

- Q:How do I get the protective film for the kraft paper on the plastic board?

- That kind of protective film only tear slowly, there is no other way. We do stickers plastic boards, customers also have this reflection, can not be solved.

- Q:How to remove the protective film on stainless steel?

- Not to tear it down. Peel it off after it's heated by air heater and then wipe the surface of the stainless steel with a warm towel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Facing Mylar for Bubble Heat Seal Composite Film and Fire-Retardant PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords