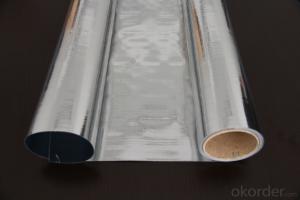

Aluminum Foil Facing, Double Sided Woven Foil for Roofing Insulation, Wall Insulation, Sarking Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Aluminum Foil Facing

Aluminum Foil Facing-DFC is a kind of film, which is made of by Aluminum foil: 7u / Tri-way fiberglass scrim: 8x12/100mm / Polyethylene /

Kraft paper: 50gsm / Polyethylene / Aluminum foil: 7u

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Aluminum Foil Facing

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Pictures of Aluminum Foil Facing

Specification of Aluminum Foil Facing

CONSTRUCTION:

Aluminum foil: 7u / Tri-way fiberglass scrim: 8x12/100mm / Polyethylene /

Kraft paper: 50gsm / Polyethylene / Aluminum foil: 7u

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD | |||||

Basic weight | gsm | 110 | ASTM D646 | |||||

Tensile strength: M. D. X. D. | N/25mm | 100 75 | ASTM C1136 | |||||

Burst strength | N | 35 | ASTM D774 | |||||

Reflectivity of foil surface | % | 95 | ---------- | |||||

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Facing, Double Sided Woven Foil for Roofing Insulation, Wall Insulation, Sarking Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords