Aluminum Foil Composite Material for Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

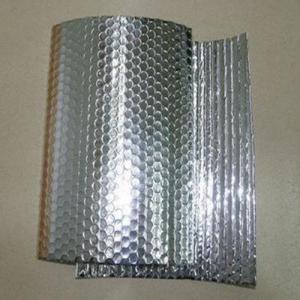

Aluminum Foil Bubble Heat Insulation

Description of Aluminum Foil Bubble:

Aluminum foil and bubble is the better product in the environmental protection, thermal insulation thermal insulation. The outermost PET has good abrasion resistance and high strength tear resistance. The bubble between the aluminum foil not only has a strong moisture, resistance oxygen, sound insulation, drop noise function, aluminum foil bubble also has very good reflective inverse heat, blocking ultraviolet.

Features of Aluminum Foil Bubble:

It is the high quality heat insulating and the invincible opponent of anti- condensation. The low and stable coefficient of heat conduction has good isolation effect.

The product has many advantages, such as light weight, heat insulation, shock absorption, sound absorption and noise reduction;

The product is easy to install and process and it also waterproof, seepage control, flame retardant.

The product also has many features, such as heat resistance, low temperature resistance, chemical resistance, ageing resistance etc.

Application of Aluminum Foil Bubble:

Building reflective heat, cold and hot water pipe insulation;

Refrigerator partition, central air conditioning, refrigerator and household appliances insulation;

Insulation, sound-absorbing, noise reduction and moisture-proof insulation in the car, train, refrigerator car, laboratory and other industries;

Special product packaging and refrigerated packing and so on.

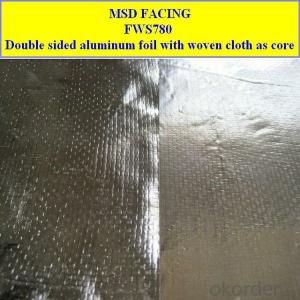

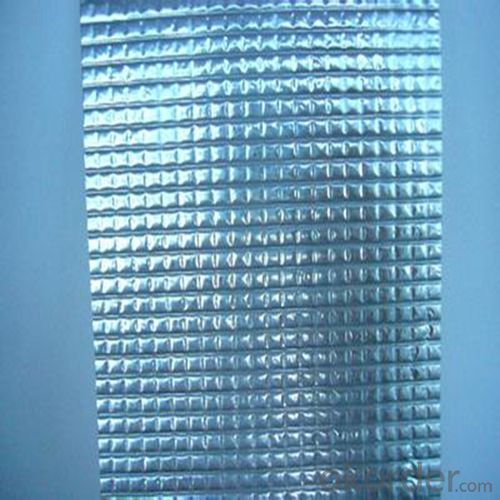

Pictures of Aluminum Foil Bubble

Specification of Aluminum Foil Bubble

STRUCTURE | ALUMINUM FOIL/BUBBLE/ALUMINUM FOIL | ALUMINUM FOIL/ BUBBLE/BUBBLE/ALUMINUM FOIL | ALUMINUM FOIL/WOVEN CLOTH/BUBBLE/WOVEN CLOTH/ALUMINUM FOIL | MPET /BUBBLE/MPET | ALUMINUM FOIL/BUBBLE/FOAM/BUBBLE/ALUMINUM FOIL |

THICKNESS | 1-4mm | 8mm | 6.5mm | 4mm | 4mm |

WEIGHT | 120GSM | 240GSM | 180GSM | 120GSM | 445GSM |

BUBBLE SIZE | 4mm HIGH x 10mm DIAMETER | 2mm HIGH x 10mm DIAMETER | 4mm HIGH x 20mm DIAMETER | 4mm HIGH x 10mm DIAMETER | 2mm HIGH x 10mm DIAMETER FOAM THICKNESS: 3.5MM |

WIDTH | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) |

THERMAL CONDUCTIVITY | 0.034w/mo | 0.032 w/mo | 0.032w/mo | 0.034w/mo | 5.87m2.k/w |

REFLECTIVITY | 96-97% | 96-97% | 96-97% | 96-97% | 96-97% |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of aluminum foil bubble insulation,is one of the large-scale professional investment aluminum foil composite insulation bases in China, consisting of both casting foundry forging and machining factory. Annually more than 100,000 square meters foil insulation are exported to markets in Europe, America and Japan. OEM service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 20 to 25 working days can be served.

④What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

- Q:This is blocking airflow and I'm having it removed after I bought the house. There is already insulation on the attic 'floor'. This is double insulated and is not correct. Why would anyone do this?

- No building codes back then, and maybe he was thinking about putting an extra room up there then you would have to insulate the rafters also

- Q:The distance between knee wall and attic ceiling is about 6 foot. Could I push a perforated pipe between the rafters?

- That is an option. And there aren't many options.Not much is going to slide easily behind the insulation. I'm thinking --------------------. You are undoubtedly going to snag on roof nails coming through the decking. I don't know if they would hold up but the cardboard tubes wrapping paper comes on might work if you tape 2 together. and flatten and tape the end you will be pushing in first. cut slots with utility knife. I think your idea would work if you can afford the pipe. That's a tough one. When we convert attics we line those cavities with a styrofoam insulation chute end to end until we reach open ventilation-you probably know that by now. Give it a try.

- Q:I have 4 pieces (about 50 sq ft) of odd shaped polystyrene foam insulation between 3" and 4" thick. it's leftover from installing a flat roof. creative ideas anyone?

- Use it as insulation in the basement. Place it under the floor along your rim joists above the foundation

- Q:I have a low pitched roof so there isn't that much room up there hands and knees only.I have no eave ventilation but the ventilation is through the front and back of the house through triagle metal caps cut into the wood siding. I already have some R19 in the ceiling joists but was wondering would putting it in the rafters against the plywood holding the shingles also help insulate the living area of the house.

- Best way and easy cheap way is just roll out unpapered fiberglass over top of joist at right angles to existing insulation

- Q:roof was replaced eight years ago soon after there were leaks in the roof caused insulation toget wet then dry now the insulation is packed hard and has started to turn into power who would be responsible to replace the insulation.

- Only you. 8 years is long past any roofer's warranty

- Q:the noise when it rains is very loud. can I place an insulation material under the polycarbonate roof to reduce noise? Thanks

- You can put it up there, but it's effectiveness at cutting noise would depend on the thickness of the insulation but you should not hope for too much reduction as the hard poly roofing is screwed or nailed directly to the rafters and is a good medium for sound transference.

- Q:My boyfriend has just moved into a flat in a newly converted house. He's up in the loft, and has just discovered that the roof isn't insulated.Does the landlord have a legal obligation to insulate the roof?

- To comply with UK building regulations all lofts must be insulated... Q22. How much loft insulation do I need? A22. To meet current Building Regulations you need 270mm of mineral wool insulation. 100mm between the ceiling joists and 170mm laid over the joists.

- Q:We had a water leak in our pipes in our foundation and had to re-route our pipes along our roof. We have tried some really basic insulation for piping, but it usually deteriorates very quickly due to sun light and wind. What are some ways we can insulate our pipes effectively without having to re-insulate every month? This has to be something fairly simple and inexpensive. We aren't looking for perfect insulation, just something that will keep the water warm in the winter and cool in the summer.

- Contact a local remodeling contractor and install the new piping system properly. Even a system under a foundation can be repaired, but it is not cheap to do it.

- Q:do i have to have insulation in my roof?

- Maybe, you do need insulation above the ceilings (it will be between the ceiling joists/framing that also serve as the attic floor joists/framing. 1. If you have a finished attic (for a living area of some sort) then yes there should be insulation with a vapor barrier under the roof &/or between the roof framing. This will help keep heating/cooling costs down and prevent condensation from forming under the roof and doing lots of water damage over time. 2. If the attic is partially finished but used for storage only & there is attic ventilation in use also then no you don't need insulation under your roof. 3. If your attic is partially finished or completely finished but used for storage only and there is no attic ventilation then yes you should have insulation with a vapor barrier also under the roof. You don't have to have it since it's used for storage only but if you start to see condensation &/or wet areas on the wood or framing under the roof then you will need insulation with a vapor barrier installed. If for any reason insulation is installed under the roof it must be installed correctly and have in place a proper method of ventilation directly under the roof itself. All roof systems in the attic areas must have proper ventilation to prevent any possibility of condensation forming under &/or in the wood roof framing & sheathing materials that will rot the wood over time.

- Q:I already have fiberglass in the attic, but would like to add more.

- Your best angle is to go with blow in fiberglass. ownes corning and Johns mansville both make good blow in fiberglass. Menards and Home depot in our area will lend you a blow in machine for free but make sure you have 2 people to run it and that you have a TIGHT sealed face mask for the guy in the attic along with safety goggles. No way around it either that guy in the attic is gonna get itchy, so expect that now. I put blow in cellulose over my attic fiberglass bats to bring it up to R-50 but i regret it now. I should have stuck with fiberglass. I did some research after the fact and there is some flammability issues with the cellulose i used and on top of that it is seriously dusty so i cant store anything in the attic space anymore. Cellulose was cheaper and the "green" choice but if i could reverse time I would have gone fiberglass blow in.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Composite Material for Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords