Aluminum Foil Coated Bubble Insulation FBBF1001

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 12000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Foil Bubble Heat Insulation

Description of Aluminum Foil Bubble:

Aluminum foil and bubble is the better product in the environmental protection, thermal insulation thermal insulation. The outermost PET has good abrasion resistance and high strength tear resistance. The bubble between the aluminum foil not only has a strong moisture, resistance oxygen, sound insulation, drop noise function, aluminum foil bubble also has very good reflective inverse heat, blocking ultraviolet.

Features of Aluminum Foil Bubble:

It is the high quality heat insulating and the invincible opponent of anti- condensation. The low and stable coefficient of heat conduction has good isolation effect.

The product has many advantages, such as light weight, heat insulation, shock absorption, sound absorption and noise reduction;

The product is easy to install and process and it also waterproof, seepage control, flame retardant.

The product also has many features, such as heat resistance, low temperature resistance, chemical resistance, ageing resistance etc.

Application of Aluminum Foil Bubble:

Building reflective heat, cold and hot water pipe insulation;

Refrigerator partition, central air conditioning, refrigerator and household appliances insulation;

Insulation, sound-absorbing, noise reduction and moisture-proof insulation in the car, train, refrigerator car, laboratory and other industries;

Special product packaging and refrigerated packing and so on

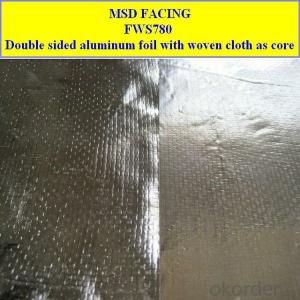

Pictures of Aluminum Foil Bubble

Specification of Aluminum Foil Bubble

STRUCTURE | ALUMINUM FOIL/BUBBLE/ALUMINUM FOIL | ALUMINUM FOIL/ BUBBLE/BUBBLE/ALUMINUM FOIL | ALUMINUM FOIL/WOVEN CLOTH/BUBBLE/WOVEN CLOTH/ALUMINUM FOIL | MPET /BUBBLE/MPET | ALUMINUM FOIL/BUBBLE/FOAM/BUBBLE/ALUMINUM FOIL |

THICKNESS | 1-4mm | 8mm | 6.5mm | 4mm | 4mm |

WEIGHT | 120GSM | 240GSM | 180GSM | 120GSM | 445GSM |

BUBBLE SIZE | 4mm HIGH x 10mm DIAMETER | 2mm HIGH x 10mm DIAMETER | 4mm HIGH x 20mm DIAMETER | 4mm HIGH x 10mm DIAMETER | 2mm HIGH x 10mm DIAMETER FOAM THICKNESS: 3.5MM |

WIDTH | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) |

THERMAL CONDUCTIVITY | 0.034w/mo | 0.032 w/mo | 0.032w/mo | 0.034w/mo | 5.87m2.k/w |

REFLECTIVITY | 96-97% | 96-97% | 96-97% | 96-97% | 96-97% |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of aluminum foil bubble insulation,is one of the large-scale professional investment aluminum foil composite insulation bases in China, consisting of both casting foundry forging and machining factory. Annually more than 100,000 square meters foil insulation are exported to markets in Europe, America and Japan. OEM service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 20 to 25 working days can be served.

④What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

- Q:I have an apartment building that has mold in it. I'm trying to do everything I can to increase the airflow. Sure, the tenants might have to spend a mint on heat, but if it improved the air quality, maybe it would be a good idea.

- Don't remove the insulation, unless it has mold in it too. Locate the source(s) of your mold problem inside your building... a high rate of interior bulk moisture, and eliminate that. Then make sure the bathrooms have exhaust fans that are wired-in with the light switch (so whenever someone turns the light on, the fan comes on too), and that the fans are vented out of your attic (otherwise you'll have mold inside your attic). Also, make sure the kitchen exhaust fans vent outside (and the clothes dryers too).

- Q:Above the trailer roof is a metal pitched roof with no soffit and lots of air-flow. I plan to recess the insulation 6" to allow airflow. There is a suggestion that I need a vapor barrier. If I use a vapor barrier, won’t water collect between the roof and the barrier. I was thinking if using strapping crosswise every 4” to act as a channel for water runoff. Any ideas?

- The roof is already a vapor barrier, you won't need 2.

- Q:i mean, what do you use to make it stay put? glue? nails?

- These are sheets of foam cut to size, they use a piece or steel wire to hold the foam up its cut some what longer then the width of the bal so it bends forcing it to dig into the joist.

- Q:Can I install rigid insulation between roof decking and shingles on a sloped roof?

- Lot of info missing to give you a good answer. Thickness of insulation. Slope of roof. But what it really comes down to is the building code in your area, contact local building inspector,

- Q:Hi, my building is hot in temperature in summers, so I am finding ways to tackle the problem by placing some heat insulating materials against the sunlight on the roof of my building. I have found several possible solutions, but none of them close to perfect. 1. grass layer: hard to maintain2. heat-insulating brick: might be too heavy to carry them to the roof3. heat-insulating coating: would it be damaged if we step on them? Are there things like heat-insulating carpets that would be convenient to instal?

- If you're redoing the roof, a radiant barrier under the sheathing helps. So does insulation. And also, if there is an attic space there, consider putting in a fan to blow the hot air out.

- Q:roof was replaced eight years ago soon after there were leaks in the roof caused insulation toget wet then dry now the insulation is packed hard and has started to turn into power who would be responsible to replace the insulation.

- Sorry; I don't know of any roofer that would take responsabilty after eight years. Unless your insurance might be an option. Check with them and decide if your deductable is more than the repair if you would be better off doing it yourself. I would also be concerned about underlying materials, sheet rock, lumber, MOLD. You need someone to check thoroughly for mold being as it has been so long. GOod luck; Flip;

- Q:we replacing our torched down rubber roof and my contractor said we need to install a 1 inch rigid insulation..is the insulation needed?

- on the outside, under the rubber? That's crazy. Don't go for it.

- Q:I have a valley between two roof peaks that gets a huge icicle every year. I know this area is not insulated very well. In the house it is a dead area between two rooms. I would like to get someone over here and blow it full of insulation (couple calls in, awaiting response). In the meantime, I do have heat tapes installed on the roof in this area. It's a 50' run, zigzagged and some goes into gutter and the downspout.I am paranoid of fire hazards and have a real problem leaving these tapes plugged in. That being said, I realize snow is all around and water is flowing in this case. Is it safe to leave these plugged in?Is there a time I should be unplugging?Will this help my icicle problem?Serious replies only please. I prefer from a licensed contractor/insulator.Thanks in advance.

- James M has a good answer- Your problems (as mine) are found in the attic - or below the roof surface. If the roof is warmed from within the house, the snow will melt daily and re-freeze at night. Your task is to keep the roof COLD by insulating the eaves from warm air. Also the attic space. The attic air should rise to a vent in gables or along the roof ridge... then exit. The interior temperature should be chilly at all times with snow on the roof- 40degF or below. In my case (maybe yours?), the warmth comes from the Top of the exterior walls - the top plate is very near the roof- and heat from the living space travels upward inside the wall to this support... a LINE of snow melt is visible where the wall meets the roof. I need to reinsulate the entire exterior to get control of roof snow melt... or visit the roof with a snow rake after heavy snow.

- Q:... building code max. (R-50)???

- The roof can also be heated enough to melt snow/ice by the sun. I wouldn't assume it's being caused by heat escaping from inside. That said, just because you have R50 doesn't mean it's perfect - it's not. Some heat will still escape. Prefect insulation is not feasible.

- Q:I do not have extra space on the roof. Roof also tapers to drains at one end of building.

- the R values, i am not sure. that white stuff is NOT Styrofoam. it is a cheap imitation. Real Styrofoam is made by DuPont, is usually a light blue, with a plastic seal coat on both sides. that thin plastic seal coat doubles the R value. what really does the insulation, is trapped air. air is actually a poor conductor of heat. the foam is actually little bubbles of air. dead air that is, air that cannot circulate and move. it works similarly to the way a down vest or coat works, it fluffs up and holds the air pockets out within a confining structure, thus retaining heat. the rigid stuff will last much longer, i can tell you that much. the white foam stuff deteriorates quickly. buy cheap, get cheap, is the general rule. you may wind up only having to do it again in a few years.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil Coated Bubble Insulation FBBF1001

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 12000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords