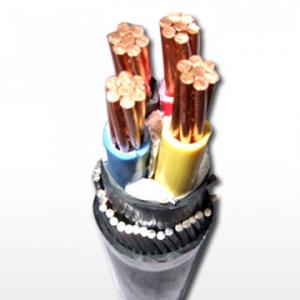

Aluminum Electrical Cable Wire,Aluminum Alloy Cable

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

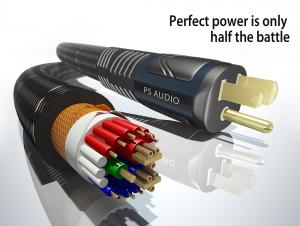

Conductivity Feature

Compare the cable with same specification, conductivity of alloy conductor manufactured by Sinyu company is 62.5% of normal international annealed copper standard (IACS). However, the actual weight of Al is one third of copper with the same volume. According to the calculation, at the premise of meeting requirements of same conductivity, length of alloy cable with the same weight is two times of copper cable. Therefore, the weight of alloy cable is half of copper cable under the same current rating. When the cross section of alloy cable is 1.5 times of copper conductor, the electrical performance is nearly the same. Cable weight could be minimized through alloy cable instead of copper cable. It could reduce the installation cost, minimize abrasion of equipment and cable and it is easy to be installed.

Anti-creepage Feature

Trend of creepage of metal under heat and pressure is greatly minimized through special alloy formula and heat treatment technology. Stability of Electrical connection by high conductivity alloy conductor is the same as copper conductor.

Thermal Expansion Coefficient

Thermal expansion coefficient is used to calculate the dimension change of material under temp variation. The thermal expansion coefficient of alloy cable is slightly higher than copper. It has more expansion and shrinkage than copper under change of same temperature.

We recommend using Copper-Al transit connector that connects the high-conductivity alloyed conductor. It has passed 1000 times thermal cycling test specified in GB 9327 (IEC 61238) standard. Reliability of electrical connection is proved. And, it completely solves problems of thermal expansion and copper-Al electrical and chemical corrosion at the connecting point of two kinds of metals by Copper-Al transit connector.

Connection Feature

The connection feature is largely improved by alloy composition in alloy conductor. That is the basic reason for being approved as ACM conductor material. Iron element enhances the anti-creepage feature. It can guarantee the stability of connection due to long-time overloads and overheat. When the connector, which is subject to 1000 times thermal cycling in GB 9327 standard, it can guarantee long-term stability and reliability of connection. It is not necessary for fastening connection of high conductivity alloy for the reason that it will damage the connection feature.

Mechanical Features

1, Rebound of high-conductivity alloy cable is 40% less than copper cable.

2, Flexibility of high-conductivity alloy cable is 24 more than copper cable.

3, High-conductivity alloy cable has better bending feature and it is easy to be connected.

4, The thermal expansion coefficient of alloy cable is slightly higher than copper. It has more expansion and shrinkage than copper. Therefore, alloy conductor could not be connected by copper connector.

Anti-corrosion

Anti-corrosion feature of alloy conductor is resulted from thin and tight oxidation layer formed through contact between alloy surface and air. The oxidation layer is resistant to various corrosion. Alloy is expansively applied to cable conductor inside the tray and many industrial components and containers account for resistance to hazard environment. Corrosion is related to connection with various metals under damp environment. Relevant protection measures shall be taken to prevent corrosion. For example, lubricant oil, antioxidant and protection coating can be applied. Insulation or sheath could be applied to buried Al conductor to prevent corrosion. In sulphur environment, such as railway, channel, sewage treatment areas, anti-corrosion feature of alloy is better than copper.

Armoring

5 xxx series Al-alloy is applied

Max. Side pressure:

Alloy cable: 4380N/m*Rm (Rm is bending radius, in m)

Armored copper cable: 3000N/m*Rm

Interlocking armoring

Magnetic material, without eddy current

Heat dissipation

Anti-corrosion

Easy to be installed

Arched armoring, disperse side pressure, smooth armoring inside, without damage to insulation

Flame-retardant

Cable Description

Alloy (R) power cable for 0.6/1kV power distribution

ZA-AC90 (-40)

Replace (WDZA) YJY/YJV/VV

Min. Operation ambient temp: -40°C

Long-term permissible temp of cable conductor: 90°C

Advantages: flame-retardant, class A, LSOH, indoor visible installation, save wireway

Picture

- Q:I lost these cables in a move so I'm looking to buy a replacement USB cable and the Power Adapter and cord. What cables do I need, and where can I buy them? :(

- I okorder - they have a nice selection, and their prices are great. If you want to be sure you're ordering the right cable, you can give them a call beforehand or click on the Live Chat feature on their site. I found mine by searching 'universal power cord' in the search box. Hope this helps :)

- Q:I live in Chicago, and I want to know if somebody can help me. The next house on mine have electrical power cable, telefon and cable from my back yard and pas my propriety aprox 60 tf, the last two stay on my garage, its legal ?Know haw i can do to move the cable? some codes or regulation, samething? Thanks, Best regards.

- If you suspect someone is in violation of the electrical code for the city of chicago call the City offices and ask for the electrical inspector ..ask them to take a look..Better safe than sorry...From the E..

- Q:A friend gave me this monitor, but didn't know where the power cord was. I made the mistake of thinking to myself quot;Oh well, it's just the standard plug, I'll just use one at home. But it is this weird 4-5 Pronged slot I haven't seen before. The manufacturer is HP, but I couldn't find any accessories on their site. Can anyone tell me what kind of plug would fit this, or where to get one? I have included a picture, sorry for the poor quality, but it is from my phone.

- blurry.. okorder /

- Q:Physically, I want to know what the cable looks like around the part that plugs into the laptop. I have a kink in the cable around that point, but don't know if cutting it and soldering is an option, depending on how complicated that part of the cable is. The rest of the cable is really simple (positive and negative) but does it get complex at the end?Note: I'm only talking about the cable, not the laptop jack itself. I'm talking about the end farthest away from the brick, that plugs into the laptop. I wanna know what that looks like, and how easy it would be to repair.

- Replacing the end of a power adapter is not something that is recommended.If not done correctly, you could surge the system board and do hundreds of dolars of damage to the PC. (At lot more than the cost of a new power adapter. The wiring it going to be unique to your make and model of computer. Check the web site of the manufacturer and see if they have a wiring diagram. If not, contact their support line. But only they can answer your question.

- Q:What kind of cable does the power cable 3 (1 * 240) +2 (1 * 120) Is it a separate cable?

- The size of the jumper varies with the specifications of the bridge, which is uncertain; the so-called repetitive ground is at least two that is the beginning and end of the end, if the length is enough, the need for intermediate isolation to do the appropriate length of the ground. Stressed that a certain attention to the ground is connected to the power grid on the ground, not directly into the ground.

- Q:what is a power cable?What does a power cable have to do with an xbox 360?Is a power cable the same thing as an AV cable?

- The power cable is the Plug that goes from the Power outlet to your Xbox360. The AV cable is the cable going from your xbox 360 that splits into 3 plugs and plugs into your tv

- Q:What fuse should I use to run my power cable to the amp?

- Measure the current (A) drawn in operation, increase by 50% and round up to the nearest standard ampacity: If the drawn current in normal operating conditions is 10A @ 12Vdc, 10*1.5 = 15A, which is one of the standard fuse ampacities (no need to round up).

- Q:Hi,1) Is spinning down of hard disk same as removing the power cable of the hard disk ? 2) Will the IDE cable connected carry power to the hard disk when the power cable is removed ?3) How do we spin down the hard disk manually ?

- 1) When you unplug the power cable, it spins down, because there is no power. In order to read data from the hard disk it needs to be spinning. When it is not spinning, you cannot read data from it. Some power saving systems will allow you set the hard drives to spin down after a long time that it has not been used, to conserve power. After that, to read from the disk it needs to be spun up, and that takes a few seconds. 2)No. 3) You cannot manually spin a hard disk, it spins at 7200 (some models 5400) rpm. That's VERY fast.

- Q:I installed a new Power supply after my old one stopped working. I bought a Thermaltake TR2 500W. I connected everything that needed to be connected but it would not turn on. Then i disconnected the 4pin cable that goes to the motherboard, and it turned on. But my monitor didn't detect anything so it just went into quot;sleep modequot;. So every time i connect the 4 pin PCI-E connection to the motherboard it just doesn't turn on. Please help

- That okorder /... If you know the PSU is good then you will know the way you wired the motherboard's connections is wrong.

- Q:Will the YJV22-0.6 / 1KV5 * 10 (cable or wire model specifications) Will this model represents what cable diameter

- Do not worry, no problem, the power cord can withstand the general high temperature, not recommended to use extension cord, the more joints more easily lead to some inexplicable problems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Electrical Cable Wire,Aluminum Alloy Cable

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords