Aluminum Die Cleaning Machine with High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Die Cleaning Machine

1. The machine discharge the waste materials out of the extrusion die by the action of hydraulic pressure, reduce erode time and improve the usage rates of material.

2.The size can be designed and customized according to customers' requirements.

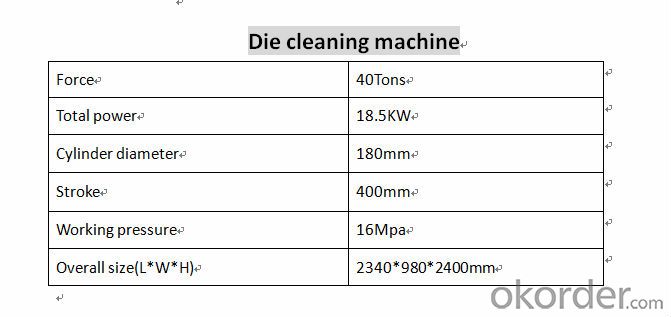

Technical parameters:

Packaging & Delivery

Packaging Details: Container

Delivery Detail: Within 40 days after received payment

Other Popular Products:

Aluminum Profile Extrusion Handling Table

Aluminum profile handling table is designed for the primary treatment after profile extruded, including the profiles' cooling, conveying, pulling, straightening, gauging and cutting. This equipment mostly for 500T-1800T aluminum extrusion press, adopt heat resistant felt belt and felt roller to convey, it can effectively avoid the profiles' secondary scraped and distorted, improve the product pass rate.

Aluminum Profile Packing Machine

The machine is designed for aluminum production packing, which is of good looking, easy operation, and low noise, good packing effect features.

Aluminum Billet Cutting Machine

The equipment can put a lot of billets on the storage table and continuously cut billets. It is mostly used in aluminium founding factory

Aluminum Profile Correction Machine

Aluminum Profile Film Sticking Machine

It has following feature: high taping speed, rigid taping effect and easy operation.The finished goods will has more competence after they are taped by this machine.

Aluminum Profile Finish Saw

The machine usually is working together with saw gauge table, it can be adjusted according to the length of extruded profiles;

Die Cleaning Machine

The machine discharge the waste materials out of the extrusion die by the action of hydraulic pressure, reduce erode time and improve the usage rates of material.

Aluminum Auto Stacker

1. The Auto stacker equip after the finish saw cutting, to storage the profile automatic;

2. Transfer many pieces of profile and the productive efficiency is high;

3. The entire productive line is controlled by computer so it is highly automatic

- Q:What are the main functions of packaging machinery and equipment?

- Such as cleaning, stacking and disassembly. In addition, also includes the measurement or the package seal etc.

- Q:Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q:How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- (1) urea formaldehyde moulding powder;The resin powder of urea formaldehyde resin, commonly known as electric jade powder, is produced by wet process, such as tree ester, curing agent, filler, colorant, lubricant, stabilizer, plasticizer and so on1 Components(1) resin used for urea formaldehyde resin molding powder by condensation reaction degree is relatively shallow, the resin with low viscosity, easy dipping filler, and can ensure the long production cycle and drying after proper fluidity, condensate in the industrial use of urea and formaldehyde at low temperature (a mixture of dimethylol urea, urea and formaldehyde) are usually used. The ratio of 1:1.5 (molar ratio), the PH=8 (and temperature) 30 - 35 of all dissolved, adding urea oxalate was 0.3% - 0.33% and 0.88% - 0.54% of the oxalic acid, then the occurrence of exothermic reaction, temperature rise, temperature in 55 - 60 degrees, and strictly control the PH=5.5 - 6.5, 60 - 75min by urea formaldehyde resin is required. Because the condensation degree is low, in fact just over addition reaction, condensation reaction is mainly in the curing process.(2) the curing agent used in curing agent and pressing powder requires latent, usually oxalic acid, phthalic acid, two formic acid, benzoic acid, chloroacetic acid, etc.(3) packing material is the most commonly used pulp, followed by wood powder or inorganic fillers (glass fiber, asbestos, mica etc.). The pulp is wood as raw material, with sodium bisulfite, non soluble cellulose impurities to the wood, and then byThat is the pure cellulose bleaching. The amount of filler material for the total amount of 25%-32%, the amount is too small, the pressure of plastic powder fluidity big, product strength is low; on the contrary, the amount of excessive pressure, plastic powder fluidity decreases, the product surface is not smooth, water

- Q:Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- This situation is best to find after sale processing, you have difficulty adjusting normal

- Q:What's the fastest packing machine?

- Depending on the characteristics of your material, the speed is adjustable!

- Q:The role of food packaging machinery

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging. The main functions of packaging machinery are as follows:

- Q:A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (3) large variance, indicating that this group of data volatility, variance is small, volatility is relatively stableAnswer: (1) a = x (501+500+503+506+504+506+500+498+497+495), 10=501,B = x (503+504+502+498+499+501+505+497+502+499), 10=501;(2) S2, =1/n[(501-501) 2+ (500-501) 2+... + (495-501) 2]=12.6,S2 B, =1/n[(503-501) 2+ (504-501) 2+... + (499-501) 2]=6.4;(3) a b > S2 dreams S2,The quality of R B packaging machine 10 bags of sweets is relatively stable.Comments on the subject, mainly on the average number, variance calculation, and their significance, the correct memory formula is the key to solving problems

- Q:What is the name of the paper used in packing machine parts and yellow?

- Also, according to the use of composite PE or textile cloth, in order to improve the physical strength and tightness.Hope to help you.

- Q:Is there anyone who knows what groups of users of packaging machinery are in general?

- Because the packaging machinery is divided into many types, so many species also have different models, basically need to use packaging products requires packaging machinery, if not to fine some, it is necessary to sort of packaging machinery, slowly down. Packaging machinery is not required to use a certain scale, packaging machinery as well as automatic, semi-automatic, manual distinction. Most small workshops, or small factories, are semi automated or manual. If some of the larger factories will use automatic, or even a whole production line to complete automated packaging.

- Q:What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Die Cleaning Machine with High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords