Aluminum Corner Profile Factory Direct from China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

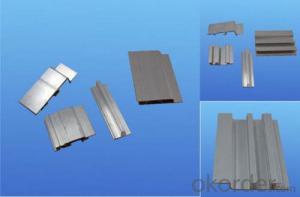

Aluminum Frame and Corner

Products Introduction of Alumium Frame and Corner

Aluminum frame is made from aluminum and minerals. It's raw matrial for window frame, window frame, and other equipment frame. It's easy for construction, cost less, service longer than other materails. The size and design can be customerized.

Advantage of Aluminum Frame and Corner

-Build FLEXIBLE equipment, window, door.

-Bolt your structure together

-Build with Aluminum MORE EASILY

-Aluminum costs LESS

-Service life is more than 10 years

-Can be customerized

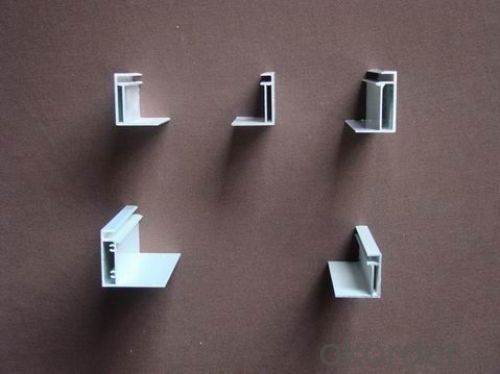

Specifications of Aluminum Frame and Corner

(1) Product: Aluminium Frame;

(2) Material: Alloy 6063/6061/6005/6060, T5/T6;

(3) Finish: anodizing, powder coating, wooden, electrophoresis or any color;

(4) Size: customized, same as drawings or samples;

(5) Standard: High-quality;

(6) Characteristics: strong, stylish, durable, corrosion-resistant.

Aluminium Alloy: 6063, 6061, 6005, 6060 Thermal Treatment: T5, T6

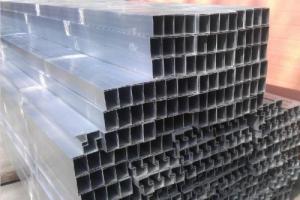

Section Shapes

I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot, and other complicated shapes by custom design.

Surface treating

Mill / Anodizing (oxidation) / Sand blasting / Powder Coating / Electrophoresis / PVDFCoating / Wood effect.

Application of Frame and Corner

1) - for Window and door frames, for Wardrobe cabinet sliding doors, kitchen, for Building curtain glass walls

2) -for Fencing, Rail, Deck and Frame.

3) - for Solar panel frames, solar mounting / roofing brackets

4) - for Industry assembly lines equipment.

5) - for Heatsinks, for LED lighting.

7) - other by custom design size and dimension

FAQ

-What's your company profile?

We CNBM is the largest building material supplier of China. We are Chinese government owned corporation, which takes the 267th place in WOLD FORTUNE 500 CORPORATION. We own the largest prodcution base in North and South of China. With more than 15 warehouses and offices in different countries, our products sell very well all over the world. We have whole quality control system. We'll be your reliable partner.

-Which kind of payment do you usually support?

TT, LC at sight.

-Can you provide samples?

Yes, we provide free of charge samples, you just need to pay for the delivery.

Photos:

- Q:How do you prevent galvanic corrosion when combining aluminum profiles with other metals?

- To avoid galvanic corrosion when combining aluminum profiles with other metals, there exist several effective measures that can be implemented: 1. Opt for compatible metals: Choose metals that are closely ranked in the galvanic series to minimize the potential difference between them. This decreases the likelihood of galvanic corrosion. For instance, utilizing stainless steel or titanium alongside aluminum can be a wise decision. 2. Insulate the metals: Employ insulating materials, like non-conductive coatings, paints, or tapes, to establish a barrier between the aluminum and other metals. This prevents direct contact and hinders galvanic corrosion. 3. Employ protective coatings: Administer protective coatings, such as anodizing or powder coating, to the aluminum surface. These coatings serve as a protective layer, preventing direct contact between the aluminum and other metals, thereby reducing the risk of galvanic corrosion. 4. Utilize isolating washers or gaskets: When fastening aluminum profiles to other metals, employ isolating washers or gaskets composed of non-conductive materials like rubber or plastic. These washers or gaskets create a barrier between the metals, thus preventing galvanic corrosion. 5. Consider design: Construct the structure in a manner that minimizes the potential for water or moisture accumulation between dissimilar metals. Adequate drainage and ventilation can help decrease the chances of galvanic corrosion. 6. Regularly maintain and inspect: Carry out routine inspections to promptly identify any signs of galvanic corrosion. If corrosion is detected, take appropriate action to rectify the situation, such as replacing damaged components or applying protective coatings. By adhering to these preventive measures, the risk of galvanic corrosion can be significantly diminished, ensuring the longevity and performance of the combined aluminum profiles and other metals.

- Q:How do aluminum profiles perform in terms of vibration resistance?

- The excellent vibration resistance properties of aluminum profiles are well-known. This is because aluminum has inherent characteristics, such as being lightweight and having a high strength-to-weight ratio, which enable it to effectively dampen vibrations. By absorbing and dissipating energy generated by vibrations, aluminum profiles reduce the risk of structural damage and ensure the integrity of the entire system. Moreover, aluminum profiles can be designed with different geometries and cross-sectional shapes, enhancing their stiffness and rigidity. This improved structural stability minimizes the transmission of vibrations throughout the profile, resulting in reduced resonance and vibration amplification. Additionally, aluminum profiles can be further enhanced through various methods, including extrusion processes and surface treatments. The use of extrusion processes allows the aluminum profiles to be shaped into specific configurations, optimizing their vibration resistance capabilities. Surface treatments, such as anodizing or powder coating, provide an additional layer of protection against corrosion and wear, thereby enhancing the longevity and performance of the profiles. In conclusion, aluminum profiles are highly effective in resisting vibrations due to their lightweight nature, high strength-to-weight ratio, and the ability to be customized for specific applications. These qualities make them an ideal choice for a wide range of industries, including automotive, aerospace, and construction, where vibration control is essential for maintaining product performance and safety.

- Q:What are the different anodizing colors available for aluminum profiles?

- There are several different anodizing colors available for aluminum profiles, including clear, black, bronze, gold, and champagne.

- Q:How do aluminum profiles contribute to water management strategies?

- Aluminum profiles play a crucial role in water management strategies due to their inherent properties and versatility. These profiles are commonly used in the construction of various water management infrastructure such as pipes, channels, and tanks, among others. Firstly, aluminum profiles are lightweight yet sturdy, making them ideal for constructing water pipes. Their lightweight nature allows for easy transportation and installation, while their strength ensures durability and resistance to corrosion. This is particularly important in water management systems as it reduces the risk of leaks and damages, ensuring the efficient and effective transport of water resources. Secondly, aluminum profiles are highly resistant to corrosion. Corrosion is a major concern in water management as it can contaminate water, reduce its quality, and damage infrastructure. By utilizing aluminum profiles, the risk of corrosion is significantly reduced, leading to improved water quality and longevity of the infrastructure. Additionally, aluminum profiles are highly customizable and can be fabricated into various shapes and sizes, allowing for the creation of efficient water management systems. These profiles can be used to construct channels, culverts, and tanks, which are crucial components of water management infrastructure. The versatility of aluminum profiles enables engineers and designers to create efficient and effective systems that can handle large volumes of water, ensuring proper water management in various scenarios such as irrigation, flood control, and wastewater treatment. Moreover, aluminum is a sustainable material that can be recycled indefinitely without losing its properties. This makes aluminum profiles an environmentally friendly choice, aligning with sustainable water management practices. By using aluminum profiles, water management strategies can minimize their environmental impact and contribute to a more sustainable future. In summary, aluminum profiles have a significant impact on water management strategies. Their lightweight yet sturdy nature, corrosion resistance, versatility, and sustainability make them indispensable in the construction of water management infrastructure. By utilizing these profiles, water management systems can be built to efficiently and effectively handle water resources, reducing the risk of contamination, improving water quality, and promoting sustainability.

- Q:In aluminum processing, countersunk holes and via holes what difference?

- Countersunk hole with flat drill or gongs knife on the board but not drilling drill (namely half hole) the transition part of the hole wall / hole wall at the maximum aperture and the minimum hole is connected with PCB parallel to the surface, size of hole part is flat, not inclined.

- Q:How do aluminum profiles compare to other materials like steel or wood?

- Aluminum profiles have several advantages when compared to other materials like steel or wood. Firstly, aluminum is a lightweight material, making it easier to handle and transport. This characteristic also translates into reduced installation time and cost. In contrast, steel is significantly heavier, which can make it more challenging to work with. Secondly, aluminum profiles have excellent corrosion resistance. Unlike steel, which can rust over time, aluminum naturally forms a protective oxide layer that prevents corrosion. This makes aluminum profiles more suitable for outdoor applications or in environments with high humidity or exposure to harsh chemicals. Furthermore, aluminum is highly malleable, allowing for easy customization and fabrication. It can be easily extruded into various shapes and sizes, making it versatile for different architectural and industrial applications. Wood, on the other hand, is limited in terms of shape and size due to its natural properties. Aluminum also offers good thermal conductivity, meaning it can efficiently transfer heat. This makes it an ideal choice for applications that require heat dissipation, such as heat sinks or radiators. Steel, on the contrary, has lower thermal conductivity. In terms of aesthetics, aluminum profiles offer a sleek and modern look, which is often desired in contemporary designs. Wood, although providing a natural and warm appearance, requires regular maintenance and can deteriorate over time. Lastly, aluminum is a sustainable material. It is 100% recyclable and can be reused without losing its original properties. Steel is also recyclable, but wood is not as easily recycled and can contribute to deforestation. Overall, aluminum profiles provide numerous advantages over other materials like steel or wood, including lightweight construction, corrosion resistance, malleability, thermal conductivity, aesthetic appeal, and sustainability. These factors make aluminum a popular choice in various industries, including construction, automotive, aerospace, and electronics.

- Q:Changhe brand aluminum can?

- Profile is not bad, but visibility is not too large, the whole is still very good, cost-effective

- Q:Can aluminum profiles be used in retail store fixture manufacturing?

- Yes, aluminum profiles can definitely be used in retail store fixture manufacturing. Aluminum profiles are widely used in the retail industry due to their versatility and durability. They can be easily customized to create various fixtures such as display shelves, clothing racks, signage frames, and product showcases. Aluminum profiles offer several advantages for retail store fixture manufacturing. Firstly, they are lightweight, making them easy to handle and install. This allows for quick and efficient fixture assembly and rearrangement. Secondly, aluminum profiles are highly resistant to corrosion, ensuring longevity and minimal maintenance. They are also available in a variety of finishes, allowing for customization to match the store's aesthetics. Additionally, aluminum profiles offer excellent structural strength, which is crucial for supporting heavy merchandise and ensuring the safety of customers. They can be easily shaped and connected using various joining techniques, enabling the creation of complex fixture designs. Moreover, aluminum is a sustainable material as it is recyclable, making it an environmentally friendly choice for retail store fixture manufacturing. This aligns with the growing trend of sustainability in the retail industry. In conclusion, aluminum profiles are an ideal choice for retail store fixture manufacturing due to their versatility, durability, lightweight nature, resistance to corrosion, customization options, structural strength, and sustainability.

- Q:Can aluminum profiles be used in the production of laboratory equipment?

- Yes, aluminum profiles can be used in the production of laboratory equipment. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various laboratory applications. It can be easily machined and is commonly used in the construction of lab benches, shelves, frames, and other equipment components.

- Q:Can aluminum profiles be painted or coated?

- Aluminum profiles possess the ability to undergo painting or coating processes. The versatility of aluminum as a material allows for easy application of paint or coating, thereby enhancing its appearance, providing corrosion resistance, and improving durability. Numerous techniques exist for painting or coating aluminum profiles, such as powder coating, anodizing, and liquid coating. Powder coating stands as a favored option due to its capacity to deliver a lasting and consistent finish, while anodizing forms a protective oxide layer on the aluminum's surface. Conversely, liquid coating offers a broad spectrum of colors and finishes. In summary, painting or coating represents an effective and practical choice for individuals seeking to alter color, enhance aesthetics, or safeguard aluminum profiles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Corner Profile Factory Direct from China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords