Aluminum Composite Foil for Cable Foil and Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Composite Foil for Cable Foil and Package

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

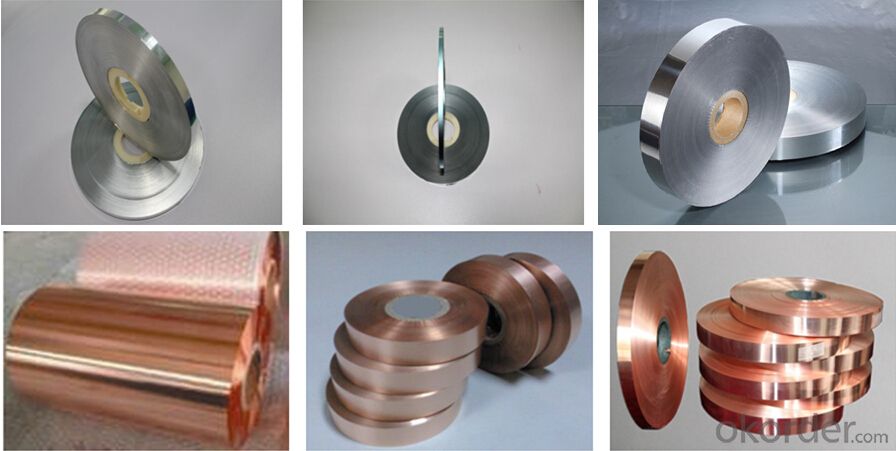

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:How to distinguish between PET gold card paper and foil gold paper peritoneum what is the difference?.

- 2.PET gold paper and aluminium foil gold paper are different in appearance:Know that the manufacturing process is more convenient appearance,.PET film is very bright, in the light of the left and right sloshing, strong reflection. Aluminum foil has a metallic luster, but there is printing layer, poor reflection

- Q:Is the self sealing bag made of pure aluminium foil or kraft paper with good sealing property?

- Of course, the tightness of the pure aluminum foil bag is good!Custom aluminum foil bag of words, I suggest looking for pure aluminum foil bag manufacturers customized experience, because it can reduce the cost and time for many of you, can give you a lot of packaging design and customized recommendations.

- Q:With aluminum foil bag vacuum packed food, placed in the pot steaming, a total of three layers, the above two layers are all right, the bottom layer is broken, what is the matter ah ~ ~!

- Because the aluminum have light luster, reverse ability, good barrier properties, impervious to gases and water vapor, temperature adaptability, high temperature or low temperature stable shape and strong shading and aroma characteristics of excellent, so the aluminum foil bag has good resistance, light resistance, barrier, permeability and appearance the appearance of the function, water vapor transmission rate can reach less than 0.015 g/ (M2 - 24h) >, also with the heat sealing function of vacuum packaging

- Q:What is the difference between aluminum foil and aluminum foil?

- For the barbecue, is the foil, but used to call it the foil (when people have never seen a foreign thing, and that is very much like a tin foil, foil)

- Q:The kitchen faucet is placed at the bottom of the cupboard. It has an aluminum foil paper. It smells great. Is it harmful to the human body? How can I get rid of it?

- Aluminum itself is harmful, long-term consumption of aluminum pollution, who will damage the brain?. When aluminum is usually passivated in the air, it greatly reduces absorption. So it's up to you to decide whether to deal with it or not.In addition, the foil is tasteless, please make sure there is dirt or so on.

- Q:Aluminum foil heat transfer of heat insulation is how, orThe old radiator looked black and looked uncomfortableA friend suggested wrapped with aluminum foil, has good heat dissipationOn the radiator, aluminum foil feel hot, not hot outHope to get your bachelor's scientific explanationThe foil blocking heat radiationThat is to say, tinfoil radiators (in the case of no gap) will affect the heat, huh

- Heat conduction is important, but for heating or air conditioning, the area of heat dissipation is more important, that is, the contact area between air and heat sink

- Q:When the wire is made, it needs a layer of foil inside, and the outside is insulated. Why is that?

- Insulation is done outside to protect or leak electricity.The cable foil is coated with plastic film on one or both sides with the tightness and shielding of aluminum foil

- Q:Can aluminum foil be harmful to human body?

- functionAluminum foil is usually used for food delivery (e.g. aluminum foil trays) and for roasting, for example, bean sprouts, potatoes, sweet potatoes, etc., are used for roasting, so as not to scorch them. Sometimes used as a decoration. The modern aluminum foil is made of aluminum and also used as an aluminum electrode for electrolysis. There are also hair stylist for foil guests perm. Some people also use aluminum foil to absorb the oil in the soup. Aluminum foil paper is also widely used in insulation, heat exchange, and as a conductor. Usually used in paper packaging, beverage packaging, and aluminum foil in food packaging bags of only 6.5 microns. This thin layer of aluminum can maintain the flavor, waterproof, anti-bacterial and anti fouling

- Q:Can I use aluminum foil in the microwave oven?

- Yes, but not any aluminum foil can be heated in a microwave oven, you can use a dedicated microwave oven aluminum foil, general supermarkets have sold it, he can control the temperature very well!

- Q:Why can copper foil and aluminum foil shield electromagnetic signals?

- Therefore, they usually back conductive adhesive, otherwise shielding effectiveness is very poor, under normal circumstances, with conductive adhesive copper foil / aluminum foil can reach more than 90dB, with flying conductive adhesive only about 40dB

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Composite Foil for Cable Foil and Package

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords