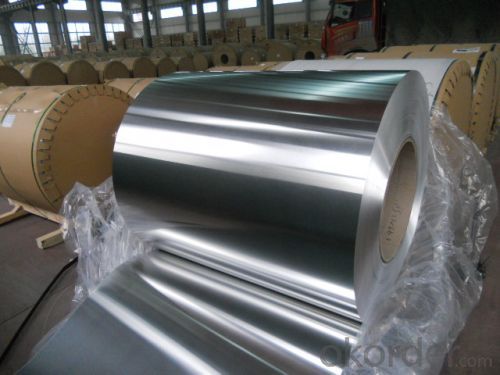

Aluminum Coil for Wine Caps Top Quality Hot Sell Hot Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | hot rolled aluminum coil for wine caps packing: wooden pallet suitable for the long distance sea transportation |

| Delivery Detail: | about 20-25 days after received your deposit or L/C |

1.Specification of hot rolled aluminum coil for wine caps

| Alloy | A1100, A3003, A3004, A5005, A8011 etc. |

| Temper | H14, H16, H18, H24 etc. |

| Thickness | From 0.024mm to 1.2mm |

| Width | From 56mm to 1600mm |

| Color | Customized, you can choose from our color chart,or we adjust the special color as the samples you offer |

| Coating | PE coating, PVDF coating, Back coating |

| Coating thickness | 0.18mm for PE coating, 0.25mm for PVDF coating |

2.Characteristic of hot rolled aluminum coil for wine caps

1) High gloss

2) High flexibility

3) Impact resistance

4) Excellent weather-proof durability

5) Anti-ultraviolet

6) High erosion resistance

7) Stable color and gloss

8) Good mechanical processing performance

9) Abrasion resistance

3.Technical information

| Item | Test Item | National standard | Test Result |

| 1 | Color Difference | ΔE≤2.0 | ΔE≤1.5 |

| 2 | Gloss Difference | ≤10 | ≤5 |

| 3 | Coating Thickness | Two layers Min 23μm | ≥25μm |

| 4 | Pencil Hardness | ≥HB | ≥HB |

| 5 | T-bend | ≤2T | ≤2T |

| 6 | Adhesion | Grade 0 | Grade 0 |

| 7 | Impact | ≥50kg.cm | ≥50kg.cm |

| 8 | Boiling water Resistance | 2h No change | 4h No change |

| 9 | Solvent Resistance | 200 times paints remaining | 500 times paints remaining |

| 10 | Acidity Resistance | 5%HCL 24hrs No change | No Change |

| 11 | Alkali Resistance | 5%NaOH 24hrs No change color ΔE≤2.0 | No Change |

| 12 | Nitric acid Resistance | ΔE≤5.0 | ΔE≤5.0 |

| 13 | Oil Resistance | 20Φ oil 24hrs No change | No Change |

| 14 | Salt Spray Resistance | 4000hrs ≤Grade 1 | No Change |

| 15 | Abrasion resistance | ≥5L/μm | ≥5L/μm |

| 16 | Dirt Resistance | ≤5% | ≤5% |

| 17 | Color retaining | 4000 hrs ΔE≤4.0 | 4000 hrs ΔE≤3.0 |

| 18 | Gloss weaken Level | 4000 hrs ≤ Grade 2 | 4000 hrs ≤ Grade 2 |

| 19 | MEK | 4000 hrs No change | 4000 hrs No change |

4.Applications of hot rolled aluminum coil for wine caps

1. Raw materials of aluminum ceiling, aluminum composite panel, aluminum sheet.

2. Mterials of aluminum signs, advertisement board

3. Roofs, wall cladding.

4. Package materials, flip off seals

Photos

- Q:When I was a kid I used to like to do all kinds of weird experimentsI noticed when I ran current through salt on aluminum paper it will create a yellowish brown substanceI never got to figure out what it wasOnly serious answers from people with knowledge about chemistry please.

- Al(3+) + NaCl + (electricity) AlCl3 (aluminum trichloride) + Na(+) the yellowish brown substance is aluminum trichloride.

- Q:My sister-in-law and I have been tasked with bringing vegetables sides for ThanksgivingA friend is already planning on bringing mashed potatoes and a whole-berry cranberry sauce (both are her specialties).My mom will make the turkey stuffing.What else should my SIL I bring?

- Bauxite is purified by washing with sodium hydroxide and then seeding with dry iceThe purified aluminium oxide is then dissolved in molten cryolite at 900 degrees C (the electrolyte)It is electrolysed with grapite anodes and a graphite cathode that acts as the vessel for the reactionAnode; 2 O2- - O2(g) + 4e Cathode: Al3+ + 3e - Al(l)

- Q:1Water and then oil (which don't mix) are poured into a U-shaped tube, open at both endsThey come to equilibrium as shown in the figure (d1 25.5 cm and d2 9.13 cm)What is the density of the oil? [Hint: Pressures at points a and b are equal.]I know that you have 2 equations and set them equal to each other, but my answer is continuously wrong2A spherical balloon has a radius of 7.85 m and is filled with heliumHow large a cargo can it lift, assuming that the skin and structure of the balloon have a mass of 1200 kg? Neglect the bouyant force on the cargo volume itself.3A 3.25 kg piece of wood (SG 0.50) floats on waterWhat minimum mass of aluminum, hung from the wood by a string, will cause it to sink?Thanks for the help in advanceAlso show work please.

- 3is true since S has to accept 2 electrons in order to become a S^2- ion.

- Q:I'm flying to Japan and want to know if i'm allowed to bring it with meHelp please!

- I would suggest asking those that said you could have done better what they would have liked insteadIt serves two purposesOne is you learn what your particular group likes, another is it gives an opportunity to say something like We're raising money for _, we don't want to spend it all For myself, I'll take whatever low cost meal is served, or none at allI'm aware of what goes into feeding a lot of people, and the expense, which is usually out of one or only a few person's pocketThe same can not be said of allOne alternative would be to have a ride where it's advertised that all donations go to the charity, and then charge a buck and a half for a burger or dog, chips, and a soda.

- Q:How many does one square meter of steel structure of the aluminum foil glass wool lap blanket cost?

- It depends on thickness and unit-weight of glass wool and the type of aluminum.

- Q:My Dad wanted to go camping, but I've never been camping before so I thought I could come here ask this questionO ya need to know what I need to bring alsoShould i check out a book on plants at the library too? 3 thx~! PLZ ANSWER

- You want the new insation on top of your blown inAny added will helpPutting it on your roof underside will trap hot air and turn your attic into a real oven.

- Q:Why aluminum foil can be used in food packaging?

- 2.Aluminum foil barrier is very good, after the metal aluminum is oxidized by oxygen in the metal surface to form a dense layer of oxide Al2O3 protective film to prevent oxygen to oxidation of aluminum metal, of course, made with aluminum foil bags to use this layer a dense protective film can be well isolated from the outside air into the interior of the bag, serve to prevent oxidative deterioration of food is a role.

- Q:it is my first time to use a microwave oven.want to know how to roast whole chicken in itwhat to use as ingredient, which pan to use, what to avoid to usethe store told us not to use wax paper or foilpls help!!!

- why would you insulation a knee wall ?

- Q:Do you need a cookie sheet to make cookies, I only have a pan.?

- When I want to make cookies, but don't want a big mess, I make peanut butter cookiesAll you need is: 1cPeanut Butter 1cBrown Sugar 1 egg 1 teaspoon Vanilla In a medium bowl mix together peanut butter and brown sugarThen add egg and vanillaStir till completely mixedIf desired you may put chocolate chips inPlace on a medium cookie sheet sprayed with oilPlace them about an inch away from each other and cook for ten minutesPreheat oven to 375 and cook for ten minutes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Coil for Wine Caps Top Quality Hot Sell Hot Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords