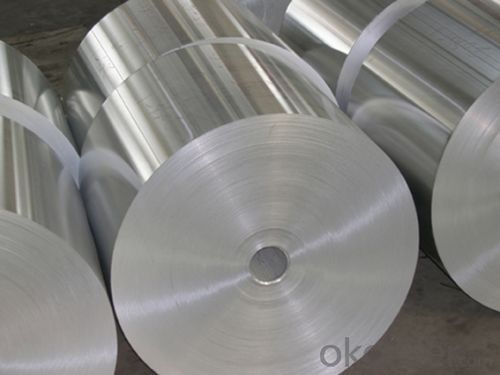

Aluminum Coil For Ceiling, Building Material In Good Price With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 10-20days or according to the order quantity |

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Parameter

Product | Alloy | Temper | Thickness | Width | I.D(mm) | Application |

Aluminum Coil/Strip | 1050,1060,1070, 1100,1200,1235, 1145,3003,304, 3105,3A21, 8011 | O H12 H14 H16 H18 H22 H24 H26 | 0.2-8mm | 50-2400mm | 75,150 200,300 400,505 (as customers's request) | construction,decoration, automobile,electronic, machinery,boat construction, aeronatics&astronautics, cookware,packing etc. |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

Photos

- Q:When you are cooking fish? I ran out of aluminum foil, all I have is parchment paper on hand. Does it matter or affect the way the fish gets cooked? Just wondering what the difference is, if any.

- The fish should cook fine in the parchment paper - it could be even better that way.

- Q:We had a BBQ a few days ago and left our pack of aluminum foil on the table out side. It rained that night and the following night. I went out to take the trash out and heard a odd noise. It was the pack of foil boiling hot. The water from the rain was steaming out of it. When I picked it up you could feel the warmth coming from the center of it.It was 2 days after the BBQ, was never near the heat of that. It was on a separate table.The table is shaded all day, so it didn't heat from the sun. Plus aluminum does not transfer heat.It just don't make since to me. I unrolled some of it and it is dark grey from being heated so hot. I never heard of it and tried to find info, but to no avail. So out of curiosity I am asking.

- Aluminum does not go wel in heat, in fact if left under extreme heat + pressure (A.K.A.) microwave, or toast oven, it will explode, there will be nothing left but tiny fragments of aluminum tinfoil.

- Q:How are aluminum coils protected against chemical exposure?

- Various methods are employed to safeguard aluminum coils from chemical exposure. One prevalent approach involves applying a protective coating or finish to the coil's surface. This coating serves as a barrier, shielding the aluminum from potentially harmful chemicals and preventing direct contact and corrosion. Another technique is anodization, whereby the aluminum surface is treated electrolytically to create a layer of oxide. This oxide layer not only provides excellent resistance against chemical exposure but also enhances the overall durability of the coils. Anodized aluminum coils find extensive use in industries like construction, automotive, and aerospace, where chemical resistance is of utmost importance. Additionally, aluminum coils can be safeguarded by employing specific alloys designed to withstand chemical corrosion. These alloys incorporate additional elements, such as copper or magnesium, which bolster the aluminum's resistance to chemical attack. By carefully selecting the appropriate alloy composition, manufacturers can ensure that the aluminum coils are better equipped to endure chemical exposure. In summary, protecting aluminum coils from chemical exposure necessitates a combination of protective coatings, anodization, and the use of corrosion-resistant alloys. These measures play a vital role in prolonging the lifespan of the coils and maintaining their performance even in harsh chemical environments.

- Q:Its currently 3 AM so i can't check, but my question is:does aluminum rust slower/faster than other metals? I've basically had this bike for about 6 years, but only rid it once. Its been sitting in my backyard under a roof (safe from rain) for 6+ years. Is it safe to ride it? Also, bonus question: Does having a bike on campus make life 10x easier?

- DUMB okorder /

- Q:Is the aluminum coil with damaged side still useful?

- The side of tire, also called side wall, is the thinnest and most fragile. Side wall damages can be divided into swell and scratch. The swell is often caused by external force (The car is trapped in pit or on curb when you are driving fast). It can cause the cord thread break so that the rubber of the tire side wall cannot be fixed and tightened. The size of the swell is often as big as that of an one-yuan coin and will become bigger as the traveling distance increases. Under such circumstance, it is recommended to replace the tire. Scratch is usually caused by bad roads or debris on the road. It is recommended to replace the tire if the scratch in the side wall is obvious and the cord thread break. If the front wheels have such damages, the tire should be replaced as soon as possible (Because the steering, braking and driving is mainly based on the front wheels.). If there is no spare tire on site, change the front damaged tire with the rear tire and drive to an appropriate place.

- Q:How do aluminum coils contribute to sustainable building practices?

- Aluminum coils contribute to sustainable building practices in several ways. Firstly, aluminum is a highly recyclable material, meaning that the production and use of aluminum coils have a minimal impact on the environment. Recycling aluminum requires only a fraction of the energy needed to produce new aluminum, reducing greenhouse gas emissions and conserving natural resources. Additionally, aluminum coils are lightweight and durable, making them an ideal choice for sustainable building practices. The lightweight nature of aluminum reduces the load on the building structure, leading to lower transportation costs and energy consumption during construction. Its durability ensures that aluminum coils have a long lifespan, reducing the need for frequent replacements and associated waste generation. Furthermore, aluminum is resistant to corrosion and requires minimal maintenance. This quality contributes to the longevity of buildings, reducing the need for repairs and replacements over time. This not only saves resources but also reduces the overall environmental impact of the building. Moreover, aluminum coils offer excellent thermal conductivity, which can contribute to energy efficiency in buildings. When used as part of insulation systems or in HVAC systems, aluminum coils help to regulate temperature and minimize energy consumption. This can result in reduced energy bills and a smaller carbon footprint for the building. Lastly, aluminum coils can be used in various applications, including roofing, cladding, and ventilation systems. Their versatility allows for creative and innovative design solutions, promoting sustainable building practices by incorporating energy-efficient features and promoting natural ventilation. In conclusion, aluminum coils contribute to sustainable building practices through their recyclability, lightweight and durable nature, resistance to corrosion, thermal conductivity, and versatility. By choosing aluminum coils for construction, we can minimize the environmental impact of buildings, conserve resources, and promote energy efficiency, ultimately leading to a more sustainable built environment.

- Q:Can aluminum coils be used for sound insulation purposes?

- Aluminum coils have the capability to serve as a means of sound insulation. This is because aluminum possesses exceptional sound-dampening attributes, which stem from its density and capacity to soak up and diminish sound waves. The utilization of aluminum coils can be witnessed in a variety of fields such as HVAC systems, the automotive industry, and construction, with the aim of diminishing noise transmission. These coils can be conveniently installed within walls, ceilings, or ductwork, thereby establishing a barrier that obstructs or absorbs sound vibrations. This, in turn, enhances sound insulation and diminishes noise levels. Moreover, the lightweight nature, durability, and corrosion resistance of aluminum coils render them a dependable choice for sound insulation solutions.

- Q:Can aluminum coils be used in the production of electrical conductors?

- Aluminum coils are indeed applicable in the production of electrical conductors due to the fact that aluminum is an exceptional electricity conductor. It possesses approximately 61% conductivity in comparison to copper and boasts advantageous features such as lightness, cost-effectiveness, and a high melting point, rendering it suitable for a variety of electrical uses. Power transmission lines, electrical cables, and transformer windings are frequently made using aluminum coils. Nevertheless, it is important to take into account that aluminum possesses a lower tensile strength than copper, which may necessitate a greater cross-sectional area to accomplish the same level of electrical conductivity. Moreover, to guarantee long-term performance and prevent oxidation, additional surface treatments or coatings may be required for aluminum coils.

- Q:Can aluminum coils be used for roofing?

- Certainly, roofing can be done using aluminum coils. Aluminum is widely regarded as a top preference for roofing materials because of its sturdy composition, lightweight properties, and exceptional resistance to corrosion. In a wide range of roofing applications, including residential, commercial, and industrial structures, aluminum roofing coils are frequently employed. They offer exceptional safeguarding against severe weather conditions like intense rainfall, snowfall, and powerful winds. Furthermore, aluminum coils possess energy-efficient attributes as they possess the ability to reflect solar heat, thereby aiding in preserving a cool indoor environment and reducing energy expenditures. All in all, aluminum coils present a dependable and enduring roofing solution.

- Q:What do you think of the stainless steel with copper and aluminum core cookware? And what's a good brand?

- Aluminum and copper are good conductors of heat, but the copper bottoms are hard to keep nicely.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Coil For Ceiling, Building Material In Good Price With High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords