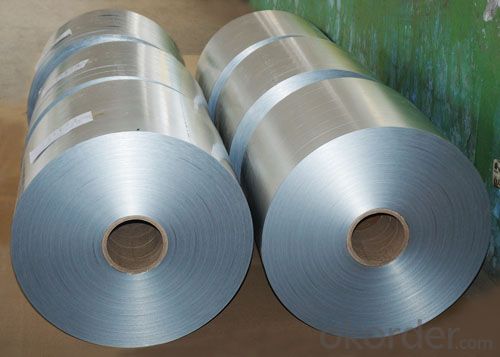

Aluminum Coil 1200 Aluminum Alloy Coil H112 Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum Coil 1200 Aluminum Alloy Coil H112 Temper

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q:What are the potential applications of coil-laminated aluminum coils?

- Coil-laminated aluminum coils have a wide range of potential applications in various industries. They can be used in the manufacturing of automotive parts, such as body panels and interior components, due to their lightweight yet durable nature. Additionally, they are suitable for building and construction purposes, including roofing, siding, and insulation, as they offer excellent corrosion resistance and thermal conductivity. Furthermore, coil-laminated aluminum coils find use in electrical industries for producing transformers, capacitors, and other electrical components due to their excellent electrical conductivity. Overall, their versatility and desirable properties make coil-laminated aluminum coils valuable in numerous applications across different sectors.

- Q:I have a 94 Gt Mustang that has had a little work done to it so far. The boy I bought it from had an aftermarket cam put in it, had the heads ported and polished. He also had the heads shaved a little. My question is.........Would having aluminum heads with roller rocker arms installed help it enough to justify doing it. If it would, how Much would it help? I am not exactly sure how much life and duration my cam is running, but it idle pretty rough. I believe my compression is about 9.5 to 1.

- If you go to roller rockers you should do it with the cam and lifters as well as the valve springs so they all match Just adding aluminum heads with roller rockers is like a fish with-out a bicycle! It doesn't make any sense. It all has to match up or you get problems instead of freer movement........and that's what rollers are about ......freeing up the drag caused by friction in the mechanical valve train.

- Q:How do aluminum coils contribute to recyclability in the construction industry?

- The inherent properties and characteristics of aluminum coils play a vital role in improving recyclability in the construction industry. To begin with, aluminum is a material that can be recycled repeatedly without losing its quality or physical properties, making aluminum coils an eco-friendly and sustainable option for construction projects. The recyclability of aluminum coils aids in reducing the environmental impact associated with the construction industry. By opting for aluminum coils, construction companies can contribute to the preservation of natural resources and the reduction of energy consumption. Recycling aluminum requires much less energy compared to producing it from raw materials, resulting in a significant decrease in greenhouse gas emissions and carbon footprint. Furthermore, the use of aluminum coils in construction simplifies the dismantling and deconstruction processes, making it easier to separate the aluminum components from other materials. This efficient separation allows for effective recycling of aluminum coils, ensuring that they can be transformed into new products or materials. Moreover, aluminum's durability and resistance to corrosion make it a suitable choice for construction applications. Its long lifespan reduces the need for frequent replacements, thereby minimizing waste generation and the consumption of raw materials. When the time comes to replace or renovate a building, the aluminum coils can be effortlessly collected, recycled, and reintroduced into the manufacturing cycle, completing the material's lifecycle. In conclusion, aluminum coils play a significant role in enhancing recyclability in the construction industry. Their high recyclability, low energy requirements for recycling, and ease of separation during deconstruction make them an environmentally friendly choice. By utilizing aluminum coils, the construction industry can promote sustainability, reduce waste generation, and conserve natural resources, ultimately leading to a greener and more circular construction sector.

- Q:I know this question is not so bright, but I am very curious why do we recycle aluminum cans? Is it that they are not biodegradable?

- We recycle cans as to save energy (and money) as the processing of aluminum cans from raw materials is very energy intensive, thus remelting them down and processing new aluminum products reduces energy use.

- Q:What are the potential drawbacks or limitations of using aluminum coils?

- One potential drawback of using aluminum coils is their relatively low strength compared to other materials like steel. This limits their application in certain industries or environments where high mechanical strength is required. Additionally, aluminum coils are more susceptible to corrosion, especially in corrosive environments or when exposed to certain chemicals. This can lead to a reduced lifespan and increased maintenance costs. Moreover, aluminum coils can be more expensive compared to other materials, making them less cost-effective in certain applications.

- Q:What are the different surface finishes for pre-painted aluminum coils?

- Pre-painted aluminum coils offer a variety of surface finishes to enhance their appearance, durability, and resistance to external factors. The most commonly used finish is Polyester (PE), which provides good durability, weather resistance, and color retention. It is available in a wide range of colors and gloss levels. Another popular option is Polyvinylidene Fluoride (PVDF) finish, known for its excellent resistance to weathering, UV radiation, and chemicals. It maintains color and gloss for extended periods, making it ideal for architectural applications. Polyurethane (PU) finish is preferred for its resistance to abrasion, chemicals, and weathering. It offers a smooth and glossy appearance and is available in various colors. PU finish is commonly used in outdoor applications that require high durability. Epoxy (EP) finish is known for its excellent chemical resistance and adhesion. It is often used in industrial applications where corrosion resistance is crucial. It can be combined with other coatings to enhance its performance. Acrylic (AC) finish provides good weather resistance and color retention. It is commonly used in architectural applications where aesthetics and durability are important. Acrylic finish offers a glossy appearance and a wide range of colors. These examples demonstrate the range of surface finishes available for pre-painted aluminum coils. The choice of finish depends on specific requirements, including desired appearance, durability, and resistance to external factors.

- Q:actually pollute more than the process of extracting it from earth and producing new aluminum?I saw a report about 5 years ago on this and was wondering if anyone else had info on this subject.

- Much less smelting required to convert pure aluminum into aluminum ingots than is needed to process boxite(?) into aluminum ingots.

- Q:Are there any specific guidelines for the storage of aluminum coils?

- Aluminum coils have specific guidelines for storage, and here are some key considerations: 1. When storing aluminum coils, it is necessary to place them in a clean, dry, and well-ventilated area. The storage facility should be free from excessive humidity, direct sunlight, and temperature fluctuations. 2. To prevent damage, handle the coils with care. Appropriate lifting equipment should be used to lift them, avoiding any bending or deformation. 3. Proper support is crucial when stacking the coils to prevent distortion or collapse. It is recommended to stack the coils horizontally on a flat surface, preferably on pallets or racks. Sufficient space should be left between each coil to allow for ventilation. 4. Protect the coils from dust, dirt, and moisture. Cover them with suitable protective materials like plastic sheets or tarpaulins to prevent contamination or oxidation. 5. Labeling each coil with relevant information, such as the alloy type, size, and production date, is advisable. This helps with easy identification and efficient inventory management. Additionally, maintaining an organized storage system prevents damage and enables efficient retrieval. 6. Regular inspection and inventory checks are necessary to identify any signs of damage or deterioration. Rotate the coils to ensure proper usage and avoid prolonged storage that could affect quality. It is important to note that these guidelines may vary depending on the specific requirements of the manufacturer or supplier. Therefore, it is advisable to consult the manufacturer's recommendations or seek professional advice for the storage of aluminum coils.

- Q:How much is one ton of aluminum coil?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.If you have any questions, please ask. I hope to help you.

- Q:my homework was to find out how do you get aluminium for rocks! I've been looking around but every web site i've been on only says that aluminium comes from rocks, but it doesn't say how you get it from rocks.e.g you get wool from sheep by shearing of their coat.so if anyone knows how you get aluminum from rocks please tell me i need your help.

- Well, you start with an aluminum rich rock (cheaper to process). The raw ore after physical concentration (removal of secondary minerals) is reacted by an electrolytic process. This means that electricity is used to convert the aluminum ion in the raw rock into the metal aluminum. Sort of like the reverse of a battery, to keep things simple. Aluminum smelters tend to be set up in places with cheap electricity, because the process uses a LOT of electricity. That is why there are several up here in quebec, we have cheap hydro electricity and the government gives decent deals to the smelters on top of the already low market price. Do a search on aluminum smelting to find out more. Not sure what your level of knowledge is so not sure how much you will understand.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Coil 1200 Aluminum Alloy Coil H112 Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords