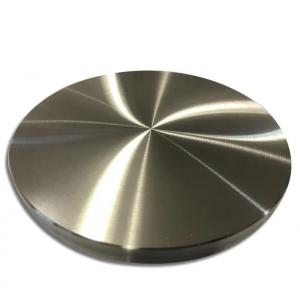

Aluminum Circle Aluminium Round Plate DC&CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification

ALUMINIUM CIRCLE

2.Description

Aluminium foil has a shiny side and a matte side. The shiny side is produced when the aluminium is rolled during the final pass. It is difficult to produce rollers with a gap fine enough to cope with the foil gauge, therefore, for the final pass, two sheets are rolled at the same time, doubling the thickness of the gauge at entry to the rollers. When the sheets are later separated, the inside surface is dull, and the outside surface is shiny. This difference in the finish has led to the perception that favouring a side has an effect when cooking. While many believe that the different properties keep heat out when wrapped with the shiny finish facing out, and keep heat in with the shiny finish facing inwards, the actual difference is imperceptible without instrumentation.

Thin sheets of aluminium are not very effective at attenuating low-frequency magnetic fields. The shielding effectiveness is dependent upon the skin depth. A field traveling through one skin depth will lose about 63 percent of its energy (it is attenuated to 1/e = 1/2.718... of its original energy). Thin shields also have internal reflections that reduce the shielding effectiveness. For effective shielding from a magnetic field, the shield should be several skin depths thick. Aluminium foil is about 1 mil (25 µm); a thickness of 10 mils (250 µm) (ten times thicker) offers less than 1 dB of shielding at 1 kHz, about 8 dB at 10 kHz, and about 25 dB at 100 kHz.

3.Why you want to choose us?

We can supply the best quality and best service!

4.Pictures

5.FAQ

1)Can we supply samples?

Yes, we can!

2)What can you do if you have other quastions?

You can contact us freely at any time!

3)How about our payment term?

LC and TT and other.

- Q:Can aluminum sheets be used for lithographic printing plates?

- Indeed, lithographic printing plates can make use of aluminum sheets. Lithographic printing, based on the principle that oil and water do not mix, involves the utilization of a metal base, typically aluminum, coated with a photosensitive layer. This layer is subsequently exposed to light, generating a pattern that serves the purpose of printing. Aluminum stands out as a favored material for lithographic printing plates owing to its exceptional characteristics. It possesses a remarkable combination of being lightweight, yet robust and long-lasting. Furthermore, its smooth surface plays a vital role in ensuring the achievement of high-quality prints. Additionally, aluminum's good thermal conductivity facilitates the rapid drying of ink during the printing process. Moreover, aluminum is highly amenable to processing and can undergo chemical treatment to enhance its surface properties, such as rendering it more hydrophilic or hydrophobic. This enables better control over the ink and water balance on the plate, resulting in prints that are sharper and more precise. In conclusion, the use of aluminum sheets for lithographic printing plates is widespread due to their desirable properties and suitability for the lithographic printing process.

- Q:Should I purchase a camper made out of aluminum/wood or a fiberglass?I'm looking to purchase a small camper, approx 18', to tow on the back of my SUV. It's a 2011 Wildwood camper. However, I hear campers made out of aluminum and wood aren't very good because the wood can ruin in time and the aluminum can rust, etc. I hear fiberglass campers are better? Anyone have any knowledge or experience with this? Also, any thoughts or advice with brands/models? And about the Wildwood? Thanks in advance.

- Aluminum is lighter so it offers economies over the life of the trailer. The Airstream has been built almost as long as I've been around. It is true that the wood does rot And some care is needed to stop the occasional leak. Fiberglass is heaver and has it's own maintenance issues. I've no experience with the Wildwood. What I do know is that motor homes are dirt cheap right now. You might think about taking advantage of the economy and pick-up a motor home at a bargain.

- Q:Can aluminum sheets be recycled indefinitely?

- Yes, aluminum sheets can be recycled indefinitely. Aluminum is a highly sustainable and recyclable material. When aluminum sheets are recycled, they are melted down and transformed into new sheets without any loss of quality or properties. This process can be repeated over and over again, making aluminum one of the most environmentally friendly materials. Recycling aluminum sheets not only helps conserve natural resources but also saves energy and reduces greenhouse gas emissions.

- Q:Are 101 aluminum sheets suitable for chemical transfer piping?

- No, 101 aluminum sheets are not suitable for chemical transfer piping as they are not corrosion resistant and may react with certain chemicals, leading to potential leaks or contamination.

- Q:i went on the apple education site cuz i was gonna order an aluminum today, and it isnt there anymore!!!! i was on it like 2 hours ago and it was...wtf!!! anyone know whuts up?

- Yes...All Aluminium Macbooks are now turned to Macbook Pros. So might want to try the Mid 2009 white macbook or you have to go with 13 Macbook Pro... vist www.parithi for details..

- Q:im about to get a grinder online, and i dont know if i should get an aluminum one, or a non aluminum one. cuz i dont know what non aluminum grinders are made out of. thanks

- Aluminum is a good choice if you plan on using it to grind more than just coffee. Plastic tends to soak up flavors due to oils in coffee, herbs and spices. So if you plan on multitasking metal is the way to go.

- Q:whst should I notice while welding aluminum sheet and aluminum block?

- two types of aluminum reach melting points, aluminum block must be preheated when you weld them with small current, you will know how to do it. You can use argon-arc welding back and forth, preheat it with small current.

- Q:How do aluminum sheets compare to other metals in terms of strength?

- Aluminum sheets generally have lower strength compared to other metals. While aluminum is lightweight and has excellent corrosion resistance, it is not as strong as metals such as steel or titanium. Aluminum has a lower tensile strength and yield strength compared to these metals, making it more susceptible to deformation and failure under heavy loads. However, aluminum can be alloyed with other elements to improve its strength, and specific aluminum alloys can rival or even surpass the strength of some other metals. Additionally, aluminum's strength-to-weight ratio is one of its main advantages, making it a preferred choice in many industries where weight reduction is crucial, such as aerospace and automotive. Overall, while aluminum may not be the strongest metal in absolute terms, it offers a balance of strength, lightweight properties, and corrosion resistance that makes it a versatile material in various applications.

- Q:doesn't particularly need to be welding but i need to make an air tight permanent seal around 2 very thin sheets of aluminium (like .02 inches thick) i was thinking .02 inch 5052 aluminum because its the thinnest i can find but am obviously up for suggestions.

- GOOP silicone adhesives are much harder when set than 100% silicone adhesives more commonly seen, but if you are just butting the tubes, epoxy to build a gusset would be a better choice. Always clean all surfaces with soap and water and then with denatured or high percent rubbing (isopropal) alcohol to improve bonding.

- Q:Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Circle Aluminium Round Plate DC&CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords