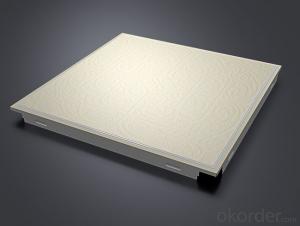

Aluminum Ceiling Panels for Interior Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: Aluminum Ceiling Tiles

Material: Aluminum sheet

Thickness: 0.45-1.0mm

System: Metric or British System

Model: Clip in, Lay in, Lay on

Edge height: 8mm, 10mm, 18mm

Surface: Powder coating, Pre-paint

Perforation: Perf. 1.8mm, 2.3mm

NRC: 0.5~0.65

CAC: 30~40

Fire proof: B1

Function: Fireproof, Heat Insulation, Moisture-Proof, Mould-Proof, Sound-Absorbing, Soundproof, Waterproof

Feature: Artistic Ceilings, Integrated Ceilings, Perforated Ceilings

EASY PLENUM ACCESS

The panels can be easily demounted by hand allowing easy and full access to services and installation in the plenum.

DESIGN FLEXIBILITY

Aluminum ceiling panel appearance provides interesting possibilities for spatial room designing.

The ceiling panel show different style pattern and shape, which engage you match your design.

A range of colors and finishes is standard available and special colors upon request.

DURABILITY

Square panel ceilings are manufactured from durable roll formed aluminum (0.5/0.6mm) or steel 0.5 mm coil, finished with a polyester paint to provide a long, low maintenance life. The coating is stove-enamelled in a continuous coil coating process ensuring uniform coating thickness and absolute adhesion.

PRODUCT CHARACTERISTIC

1) Surface smoothness and easy cleaning ;

2) Flexible suspension system makes each ceiling tile easily installed and disconnected;

3) Easy to match lamps or other ceiling parts;

4) Surface color can be stable for 10 years by indoor use;

5) Function: Acoustical, Fireproof, Waterproof, Washable, Light reflect.

- Q:Bathroom ceiling plate ceiling from the ceiling is the smallest number

- Preferably not less than 10cm

- Q:Aluminum cords hanging ceiling, you can turn it?

- es, the board Needless to say, processed into a circular arc Under the words, the corners are generally L-type, you can cut the corner of the place with scissors cut, bent into the garden, but this may cause a saw porcelain The shape of the need for plastic, if it is white or solid, you can draw two arcs arc, arc angle is equal to you need to do circular curvature of the anastomosis, arc size is equal to the width of the corner, you can try

- Q:Mirror aluminum ceiling for the kitchen is good, choose which brand of high cost, it will absorb fumes?

- Yes, the American standard is not bad Oh.

- Q:How can I install an aluminum cords with a ceiling?

- The correct construction sequence is like that.

- Q:What are the properties of aluminum?

- Aluminum heaters are often used to melt refractory metals and welded rails. Aluminum is also used as a deoxidizer in the process of steelmaking. Aluminum powder and graphite, titanium oxide (or other high melting point metal oxide) according to a certain ratio of uniform mixing, coated on the metal, the high temperature calcination and made of high temperature resistant cermet, it has important applications in rocket and missile technology The

- Q:Recently home house in the decoration, to see a lot of integrated ceiling model. Now very depressed is the integrated ceiling and aluminum buckle plate integrated ceiling in the end what is the difference? Is it the same thing? Very depressed ~

- The first type of aluminum-magnesium alloy, which contains some of the manganese, the biggest advantage of the material is good antioxidant capacity, and because adding the right amount of manganese, the strength and stiffness to improve, is the best material ceiling. The second type of aluminum - manganese alloy, the strength and stiffness of the plate is slightly better than the aluminum - magnesium alloy, but the antioxidant capacity is slightly inadequate; The third type of aluminum alloy, the plate contains manganese, magnesium less, so its strength and stiffness are significantly lower than the aluminum-magnesium alloy and aluminum-manganese alloy, antioxidant capacity in general.

- Q:3DMAX kitchen ceiling in the aluminum plate with what map? I am a novice

- The map is not fixed. You use pattern, wood, stripes, or on a color line. It is important that you tune the material. pictures look to know

- Q:Aluminum plate is not only corrosion-resistant, and light weight, do not absorb moisture, according to experience the use of decades is not a problem.

- Do not say that you do not regulate the sauna board, that is, the use of norms is not as good as the use of aluminum buckle trouble.

- Q:Home improvement integrated ceiling of the aluminum plate, film and roller coating where the difference? Look detailed, thank you ~!

- It is recommended that you do not choose the surface treatment of the film! Because the surface treatment of the film is easy to change color, the production process is simple (currently the most expensive buckle on the market are mostly covered) One of the main ways to identify the film is to use your fingertips (or pen) percussion, the sound is not crisp hair muffled sound is covered If the sound is very crisp is the recommended several of the above process!

- Q:The kitchen lights in my house are broken! Ceiling lights are with the buckle board together, do not know where to start out, I would like to ask you how to get big? Need tool not? Thank you! anxious

- This depends on the type of ceiling board to choose the appropriate solution. Specifically, it is divided into the following two cases: 1, the ceiling of the board for the square board (the general specifications in the 30 cm or so square), first remove the ceiling next to a square plate, using a wallpaper knife blade into the ceiling lamp and the surrounding square between the gap of a certain size And then the blade will pry the square around the ceiling lamp and then take the board from the side of the side where the board has just been leveraged. After the ceiling of the connection to the wire to be replaced after the replacement of ceiling lights. To be finished after the lamp, and then re-install the square board can be removed just. 2, the ceiling of the board for the board (that is, long strip), to remove the ceiling lamp, you need to ceiling lights on both sides of the strip on both sides of the buckle first removed, and then take the board and change the lights.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Ceiling Panels for Interior Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords