Aluminum Alloy Profile Extrusion for Windows and Doors Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminum Alloy Profile Extrusion for Windows and Doors Frame

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2. Application of Aluminum Alloy Profile Extrusion for Windows and Doors Frame

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Alloy Profile Extrusion for Windows and Doors Frame

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

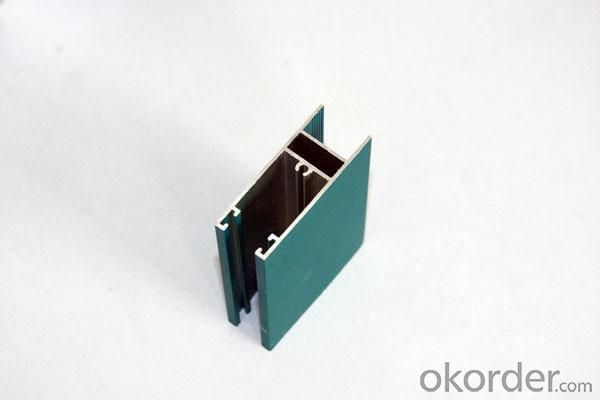

5. Image of Aluminum Alloy Profile Extrusion for Windows and Doors Frame

6. Package and shipping of Aluminum Alloy Profile Extrusion for Windows and Doors Frame

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q:How do aluminum profiles contribute to sustainable building practices?

- There are several reasons why aluminum profiles are crucial in promoting sustainable building practices. To begin with, aluminum is a material that can be recycled multiple times without any loss in quality. This recyclability significantly reduces the need for extracting and processing new aluminum, which is a process that consumes a lot of energy and harms the environment. By using aluminum profiles in construction, we can greatly reduce the demand for new aluminum production and thus conserve natural resources and decrease carbon emissions. In addition, aluminum profiles are both lightweight and strong, making them ideal for creating energy-efficient structures. Their lightweight nature reduces the load on the building's foundation and structural elements, resulting in lower material requirements and reduced construction costs. Furthermore, a lighter structure requires less energy for heating and cooling, leading to decreased energy consumption and reduced greenhouse gas emissions throughout the building's lifespan. Moreover, aluminum profiles have excellent thermal and acoustic insulation properties. When used correctly, they can contribute to the overall energy efficiency of a building by minimizing heat loss or gain through windows and doors. This means that less reliance is placed on artificial heating and cooling systems, resulting in decreased energy consumption and lower utility bills. Another advantage of aluminum profiles is their durability and low maintenance requirements. They are resistant to corrosion, weathering, and UV rays, which ensures a long lifespan and reduces the need for frequent replacements and repairs. This not only saves resources but also reduces waste generation and the use of landfills. Finally, aluminum profiles offer great design flexibility and can be easily incorporated into various architectural styles and designs. This versatility allows architects and builders to create structures that are both visually appealing and functional, while still adhering to sustainable building practices. In conclusion, aluminum profiles contribute to sustainable building practices by being recyclable, lightweight, energy-efficient, thermally insulating, durable, low maintenance, and versatile. By using aluminum profiles in construction projects, we can reduce our environmental impact, conserve natural resources, and promote a more sustainable future.

- Q:What are the different surface patterns or textures available for aluminum profiles?

- There are various surface patterns or textures available for aluminum profiles, including smooth, brushed, anodized, textured, embossed, and patterned finishes. These different finishes offer a range of aesthetic and functional options, allowing for customization and versatility in various applications.

- Q:What are the color options available for aluminum profiles?

- The color options available for aluminum profiles are vast and diverse. Standard options usually include silver, bronze, and black anodized finishes. However, these profiles can also be powder-coated in a wide range of colors, allowing for customization to match any aesthetic or design preference.

- Q:Can aluminum profiles be used for creating lighting fixtures?

- Yes, aluminum profiles can be used for creating lighting fixtures. Aluminum is a popular material choice for lighting fixtures due to its lightweight nature, durability, and corrosion resistance. It is also easily shaped and machined, making it suitable for creating various designs and styles of lighting fixtures. Additionally, aluminum profiles can be powder-coated or anodized to enhance their appearance and provide additional protection against wear and tear. The versatility and aesthetic appeal of aluminum make it an ideal choice for creating lighting fixtures in a wide range of settings, including residential, commercial, and industrial applications.

- Q:What are the different types of hinges used with aluminum profiles?

- Aluminum profiles offer various options for hinges, each serving a specific purpose. Here are a few examples: 1. Butt hinges, the simplest type, consist of two plates connected by a pin. They facilitate smooth opening and closing of doors or panels. 2. For larger or heavier doors, piano hinges are ideal. These lengthy, narrow hinges run the entire length of the door, providing additional support and stability. 3. Concealed hinges, as the name implies, remain unseen when the door or panel is shut. They are perfect for achieving a seamless appearance, commonly used in cabinet doors. 4. Pivot hinges enable doors or panels to pivot on a single point. They are suitable for taller doors or those needing to swing in both directions. 5. European hinges, also known as cup hinges or hidden hinges, are adjustable and ensure a smooth opening and closing motion. These are commonly found in cabinet doors. 6. In high-traffic areas or where door closure is crucial, self-closing hinges are equipped with a spring mechanism that automatically closes the door or panel after opening. These examples demonstrate the variety of hinges available for aluminum profiles. The choice of hinge depends on factors such as the application, size and weight of the door or panel, desired aesthetics, and functional requirements.

- Q:How do aluminum profiles provide structural stability?

- Aluminum profiles provide structural stability through their inherent properties such as high strength-to-weight ratio and excellent corrosion resistance. These profiles are designed to distribute and withstand loads efficiently, ensuring the structural integrity of various applications. Additionally, their versatility allows for customization and integration with other materials, further enhancing stability in different environments and industries.

- Q:What are the different assembly options available for aluminum profiles?

- There are several assembly options available for aluminum profiles, depending on the specific requirements and applications. Some of the common assembly methods include: 1. Mechanical Fastening: This involves using screws, bolts, or rivets to join two or more aluminum profiles together. Mechanical fastening provides a strong and secure connection and is suitable for applications that require frequent disassembly or adjustment. 2. Welding: Aluminum profiles can be welded together using various welding techniques such as TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding. Welding provides a seamless and strong joint, making it ideal for applications that require maximum strength and rigidity. 3. Adhesive Bonding: Adhesive bonding involves using adhesives or glues to join aluminum profiles together. This method is suitable for lightweight applications or where aesthetics are important, as it provides a clean and seamless appearance without visible fasteners. However, adhesive bonding may not be as strong as mechanical fastening or welding. 4. Slotting and Connecting Elements: Aluminum profiles often have T-slot designs that allow the use of various connecting elements such as T-nuts, connectors, and brackets. These elements can be easily inserted into the slots and tightened to create a secure and adjustable joint. This method is particularly useful for applications that require flexibility and easy reconfiguration. 5. Corner Brackets: Corner brackets are specifically designed to connect aluminum profiles at right angles. These brackets can be easily attached using screws or bolts and provide a strong and rigid joint. Corner brackets are commonly used in frame construction or for creating corners in structural applications. 6. Interlocking Systems: Some aluminum profiles feature interlocking systems that allow them to be connected without the need for additional fasteners or connectors. These systems use specially designed shapes or grooves that fit together, providing a secure connection. Interlocking systems are often used in modular structures or systems that require quick assembly and disassembly. Overall, the choice of assembly method for aluminum profiles depends on factors such as strength requirements, aesthetics, ease of assembly, and the specific application or industry. It is important to carefully consider these factors to select the most suitable assembly option for a given project.

- Q:Are aluminum profiles suitable for railway and transportation systems?

- Yes, aluminum profiles are highly suitable for railway and transportation systems. Aluminum is a lightweight and strong material, making it ideal for applications that require high strength-to-weight ratio, such as the construction of railway and transportation systems. One of the key advantages of using aluminum profiles in these systems is their excellent corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface, which prevents rusting and corrosion, even in harsh environmental conditions. This ensures the longevity and durability of the railway and transportation systems, reducing maintenance requirements and costs. Additionally, aluminum profiles offer design flexibility. They can be easily fabricated into various shapes and sizes, allowing for customization to meet specific requirements of railway and transportation systems. This versatility enables the development of lightweight yet robust structures that can withstand the dynamic loads and vibrations experienced in transportation applications. Another benefit of aluminum profiles is their recyclability. Aluminum is one of the most recyclable materials, with a high recycling rate. This makes it an environmentally friendly choice for railway and transportation systems, aligning with sustainable practices. Furthermore, aluminum profiles have excellent electrical conductivity and thermal properties. This makes them suitable for applications that require efficient heat dissipation, electromagnetic shielding, or electrical connections in railway and transportation systems. In summary, aluminum profiles are highly suitable for railway and transportation systems due to their lightweight, strength, corrosion resistance, design flexibility, recyclability, and electrical and thermal properties. These qualities make aluminum an ideal material for constructing durable, efficient, and environmentally friendly transportation infrastructure.

- Q:Can aluminum profiles be used in HVAC system manufacturing?

- Aluminum profiles are indeed applicable in the manufacturing of HVAC systems. Their lightweight nature, durability, and exceptional thermal conductivity make them highly suitable for HVAC applications. These profiles can be utilized in constructing various components such as air ducts and heat exchangers. Their corrosion resistance is also vital for ensuring the longevity and effectiveness of HVAC systems. Moreover, working with aluminum profiles is effortless, enabling customization and flexibility in the design and construction of HVAC systems. In conclusion, the numerous advantageous properties of aluminum profiles make them a favored option in the manufacturing of HVAC systems.

- Q:How do I cut and shape aluminum profiles?

- To cut and shape aluminum profiles, you will need specific tools such as a miter saw, a hacksaw, or a circular saw with a carbide-tipped blade. Measure and mark the desired length on the profile, ensuring accuracy. Use a miter saw or a hacksaw to cut the aluminum along the marked line. For shaping, you can use a file or a deburring tool to smooth out any rough edges. Additionally, if you need to bend the aluminum, a sheet metal brake or a vise can be used. Always wear appropriate safety gear, such as gloves and safety glasses, when working with aluminum profiles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Alloy Profile Extrusion for Windows and Doors Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords