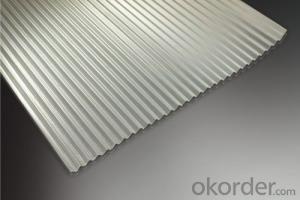

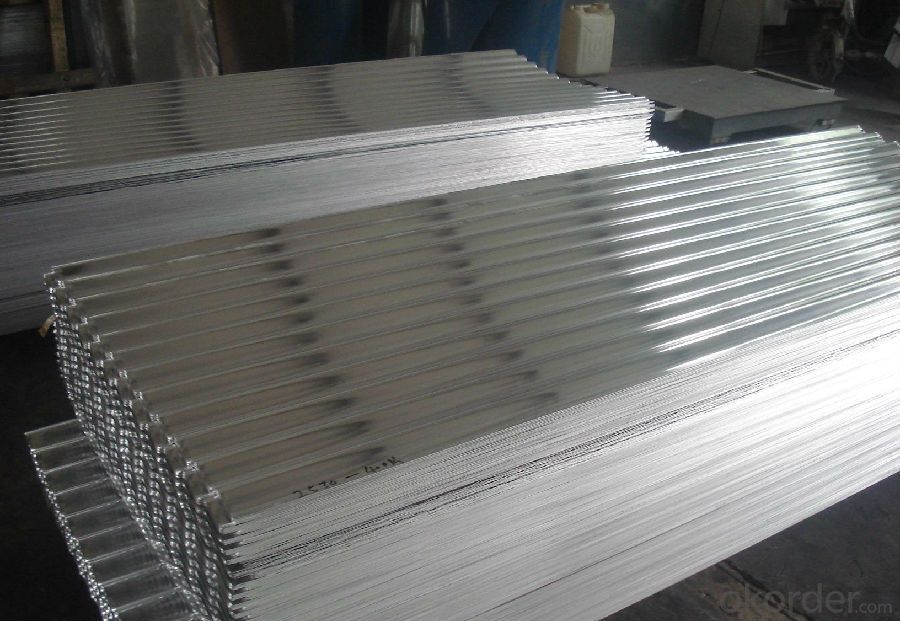

aluminum 4ft x 8ft sheets corrugated roofing sheet roof tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specification

| commodity | aluminum 4ft x 8ft sheets corrugated steel roofing sheet color steel roof tile roofing |

Grade | SGCC SGCH DX51D |

Standard | ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008 AS1397-2001, EN10215-1995, ASTM A792M-02, JIS G3321-1998 |

Basal plate | Cold rolled steel coil ,hot dipped galvanized/galvalume steel coil |

Zinc Coating | Z30-Z275G/m2, AZ30-150g/m2 |

Thickness | 0.13-0.9mm |

Width | 750-1250mm(before corrugation) 600-1050mm(after corrugation) |

Wave depth | 18(+/-2mm),etc |

Wave distance | 76(+/-2mm),etc |

| color | according to RAL |

| length | as your requestment |

| Product feature | water resistance,light weight,easy installation,aesthetic,high tensile |

| Packing | standard export water-proof package with steel strips fixed |

| Coating | Top:10-25um back:5-10um |

| Application | exterior and interior wall,roofs,and soffits |

| Advantages | 1.Design according to customers 'requirements 2.Production under ISO9001-2008 Quality System 3.Easy to be installed as light weight 4.Z360-275/AZ30-150 is suitable for many application 5.Our products are recyclable materials 6.The less construction period, the more using time. |

Production line

We have six producting line of color aluminum tile. Our annual output is 8000 ton,due to the most advanced and mordern lines

why choose us

our advantage of color steel tile

1.corrosion resistance

2.light weight:Metal covered and metal frame buildings offer the safest possible shelter during the storms. Correctly earthed aluminium, because of its high electrical conductivity, offers excellent protection from lighting damage.

3.High strength:bending and compression resistance, used as building enclosure and bearing structure

4.Easy to install:no need special tools, do not break, crack or leak.

5.Energy-saving:saving of the structural steel by up to 40%.

6.Beautiful design

7.Quake-proof, fire-proof, rain-proof.

8.It can be recycled and good for environments.

our service for you

pre-sale service

1.sample free

2.We have full stock and can deliver within short time

3.Dood quality+factory price+quick response+reliable service

4.All of our products are produce by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

After you choose

1.we will count cheapest shipping cost and make invoice to you at once

2.check quality again,then send out to you at 5-10 working day after your payment

3.email you the tracking No,and help to chase the parcels until it arrive you

After sale choose

1.we are very glad that customer give us some suggestion for price and products

2.If any question,please contact with us freely by E-mail or telephone

Our products are very popular to be exported to the Russian market,Korea South-East Asia,India,Middle-East,Africa,North-Europe,South- America,and so on.

- Q:What is the typical wear resistance of aluminum sheets?

- The typical wear resistance of aluminum sheets can vary depending on factors such as alloy composition, tempering, and surface treatment. However, in general, aluminum sheets have relatively low wear resistance compared to materials like steel or titanium. They are more prone to scratching, abrasion, and surface damage. To enhance wear resistance, additional coatings or treatments can be applied to aluminum sheets.

- Q:Wonderland is the hard aluminum with what tools do? Thank you

- Wrought iron platform made 3 aluminum alloy with a hard aluminumAluminum + granite can also be synthesized

- Q:Are 101 aluminum sheets magnetic?

- No, 101 aluminum sheets are not magnetic. Aluminum is a non-magnetic metal, which means it does not attract or hold a magnetic charge.

- Q:Okay, so i swallowed some aluminum foil like the size of a quarter from my fruit rollup wrapper, ha don't ask why? but my stomach KINDA hurts right now...like 2 minutes later.. Could this have done any damage to me.?

- You'll be fine! It should ball up and you'll eventually pass it! (BLAH) My dog actually ate an entire aluminum foil cupcake tin once! He passed it in a day or 2 (Not that I'm comparing you to a dog! But same kinda thing!) Your stomach kinda hurts probably cause you're freaking out! Our minds like to play tricks on us that way. But if you end up getting lower abdo pain in the next 12-24 hours (sharp, stabbing) then better get it checked out! Good Luck! Watch out for those wrappers next time! ha

- Q:How do aluminum sheets perform in terms of creep resistance?

- Aluminum sheets generally exhibit good creep resistance, especially when compared to other metals. Aluminum has a low melting point and high thermal conductivity, which helps in reducing creep deformation. It also has a fine-grained microstructure that enhances its resistance to creep. However, it is important to note that the creep resistance of aluminum sheets can be affected by factors such as temperature, load, and alloy composition.

- Q:How is the strength and durability of aluminum sheets determined?

- The strength and durability of aluminum sheets are determined through a variety of testing methods and parameters. One of the primary factors that determines the strength of aluminum sheets is the alloy composition. Different alloy compositions have varying levels of strength, and certain elements added to the aluminum can enhance its strength properties. To evaluate the strength of aluminum sheets, tensile testing is commonly employed. This involves subjecting a sample of the sheet to tension until it fractures. During the test, the load and deformation are measured, and the ultimate tensile strength (UTS) and yield strength are determined. UTS represents the maximum stress the sheet can withstand before failure, while yield strength is the stress at which the material begins to deform plastically. Another important consideration for determining the strength and durability of aluminum sheets is the thickness. Generally, thicker sheets tend to be stronger and more durable than thinner ones due to the increased cross-sectional area contributing to load-bearing capacity. In addition to alloy composition and thickness, the manufacturing process also affects the strength and durability of aluminum sheets. Factors such as rolling and heat treatment can alter the microstructure of the aluminum, influencing its mechanical properties. Proper control of these processes helps ensure consistent strength and durability across the sheets. Furthermore, aluminum sheets are often evaluated for their resistance to corrosion. Aluminum naturally forms a protective oxide layer, which contributes to its corrosion resistance. However, specific coatings or treatments can be applied to enhance this resistance, depending on the intended application. In summary, the strength and durability of aluminum sheets are determined through a combination of alloy composition, thickness, manufacturing processes, and testing methods such as tensile testing. These factors collectively dictate the mechanical properties and resistance of aluminum sheets to various forms of stress, making them suitable for a wide range of applications.

- Q:Are aluminum sheets suitable for automotive heat shields?

- Yes, aluminum sheets are suitable for automotive heat shields. They have excellent thermal conductivity and high melting point, making them effective in dissipating heat and protecting sensitive components from excessive temperature. Additionally, aluminum is lightweight and corrosion-resistant, which are desirable qualities for automotive applications.

- Q:Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q:Can aluminum sheets be used for interior design purposes?

- Yes, aluminum sheets can definitely be used for interior design purposes. Aluminum is a versatile material that offers many benefits for interior design applications. It is lightweight, durable, and resistant to corrosion, making it ideal for various design elements such as wall coverings, ceiling panels, backsplashes, and room dividers. Aluminum sheets can be easily customized and fabricated into different shapes, sizes, and finishes, allowing for endless design possibilities. Additionally, aluminum is a sustainable and eco-friendly material, as it is highly recyclable. Its sleek and modern look adds a contemporary touch to any interior design project. Overall, aluminum sheets have become a popular choice for interior designers due to their functionality, aesthetics, and sustainability.

- Q:Consider an aluminum wire of diameter 0.580 mm and length 28.0 m. The resistivity of aluminum at 20.0°C is 2.82 10-8 Ω · m.(a) Find the resistance of this wire at 20.0°C. ___________Ω(b) If a 9.00-V battery is connected across the ends of the wire, find the current in the wire. __________A

- Aluminum has a resistivity of 2.65 x 10^-8. But I will use your figure of 2.82 x 10^-8. R = ρL/A where ρ = resistivity = 2.82 10-8 Ω · m, L = Length = 28 meters, A = Area =( .58mm/2)^2 x pi = 0.26 mm^2, or 2.6 x 10^-7 m^2 R= (2.82 x 10^-8)(28)/2.6 x 10^-7 = 3.03 ohms I=V/R = 9/3.03 = 2.97 amps

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

aluminum 4ft x 8ft sheets corrugated roofing sheet roof tile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords