aluminium wires AA1050 with high purity and low price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Solid MIG and TIG wires for welding pure aluminium

2.excellent ductlity,corrosion resistance

3.well electrical conductivit

Detailed Introduction

Product name:Aluminum

Type: pure aluminum

Melting point: 660°C(1220°F)

Boiling point:2467°C(4473°F)

Density under 20°C(60°F): 2.70g/cm3

Application:

Just like silicon, aluminum is a common deoxidizer. Aluminum is also used as grain refiner and occationally as heating material. Aluminum wire permits to achieve high and constant Aluminum recovery. Please note that late aluminum wire feeding during refining can cause solid alumina inclusions to appear which will affect steel castability. Calcium cored wire addition can remedy this situation by transforming solid alumina into liquid calcium-aluminates.

Specification

Dia 9mm cored wire is a kind of medium size wire, which is suitable for the ladle of capacity less than 20 MT and most of cast iron spheroidization

Φ9mm Cored wire Specification

* The above specifications can be adjusted upon request.

Dia 13mm cored wire is a typical size wire for steel industry, which is suitable for all kinds of steel ladles and alloys.

Dia 16mm cored wire is suitable for the alloy adding to the steel ladle of capacity more than 250MT.

Φ13mm - Φ16mm cored wire specification

* The above specifications can be adjusted upon request.

Diameter and fill rate

Diameter and fill rate

Products | Diameter and fill rate(g/m) | Application | ||

Φ9mm | Φ13mm | Φ16mm | ||

CaSi | 110 | 220 | 330 | Steel desulphurization, deoxidization, inclusion modification and castability |

CaFe | 122 | 250 | 365 | Low silicon Steel modification, inclusion modification and steel desulphurization, deoxidization, clogging prevention, castability |

AlCaFe | 150 | 300 | For low silicon steel application, besides the function of CaFe cored wire but steel deoxidization and grain refinement | |

FeTi | 165 | 370 | 570 | Microalloying and deoxidization |

FeBo | 200 | 550 | 825 | Microalloying |

C | 140 | 205 | Trimming addition, steel carbon adding | |

Mg | 60 | 140 | 210 | Desulphurization and nodularisation |

FeSiMg | 235 | 335 | Nodularisation | |

CaSiBa | 225 | 330 | Inclusion modification | |

Al | 200 | 300 | Deoxidization and grain refinement | |

S | 190 | 280 | Re-sulphurising of free cuting steels | |

FeSi | 235 | 335 | Nodularisation | |

The above fill rates can be adjusted upon request. The thickness of steel strip is 0.35~0.50mm, which conforms to the stipulation of GB716,GB3526,GB1323. The weight allowance for each 200g is no more than 2.5%. The joints for each 1000 meters are no more than 3. The cored wires are widely used for calcium treatment and microalloying in the ladle metallurgy, which have the advantages of element precise control and easy use. | ||||

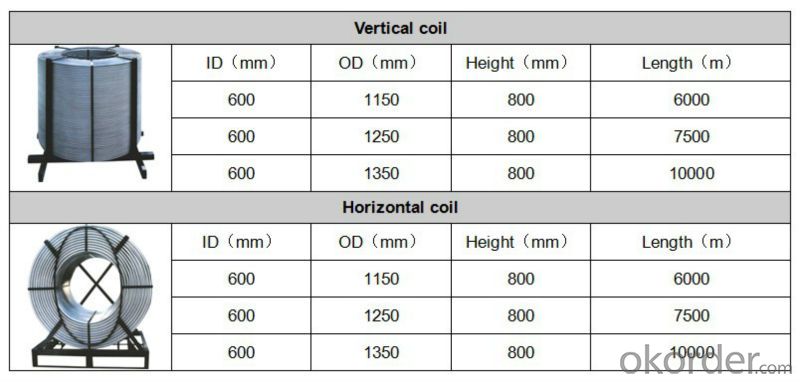

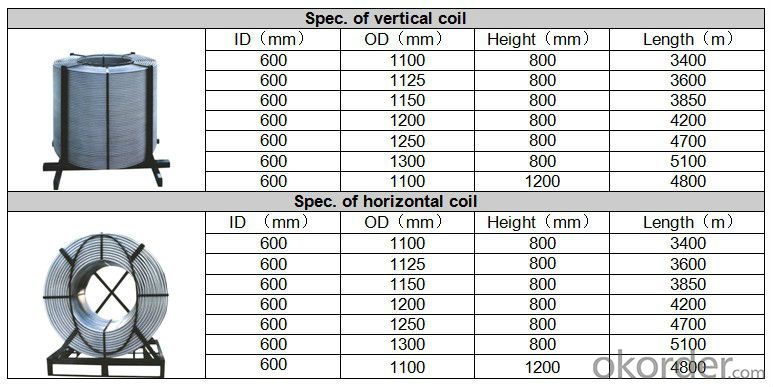

Packing

Based on the design of feeding machine, cored wire coils can be made vertically or horizontally, With the special connector, the coils can be fed continuously, The packing also can be customized upon request.

- Q:What can not be used for fuse?

- Fuse made of nickel chromium alloy wire, its melting point is low, in the case of high voltage will fuse, thereby disconnecting the circuit, to protect the purpose of the circuit!

- Q:There are several aluminum wires in the high voltage 50mm aluminum cable

- So the high pressure 50mm - aluminum core cable inside each aluminum conductor of not less than 19 of aluminum wire.

- Q:How to remove the air in the drawing mark of aluminum material?

- In aluminum wire drawing process, anodized after special coating technology, can make the surface of aluminum to form a coating layer containing the metal component, clear every fine wire mark

- Q:Which heat transfer is copper wire, wire or aluminum wire fast?

- The greater the heat conductivity, the faster the heat transfer

- Q:Manufacturing process of LED device

- As the LED chip is still closely spaced after dicing, the spacing is very small (about 0.1mm), which is not conducive to the operation of the subsequent process. We use the expansion machine to expand the film on the bonding chip, and the LED chip spacing is stretched to about 0.6mm. Manual expansion can also be used, but it is easy to cause chip waste, waste and other undesirable problems.

- Q:The difference between traditional resistance welding and aluminum wire welding

- Mainly used for welding large modules,Resistance welding is the use of current through the base material, because the parent material resistance and heat generated by welding methodsMainly used for higher precision, more stringent appearance of the workpiece,

- Q:How to tell how thick the wire is?

- Usually, the diameter of the wire retains two decimal places, so the diameter of the 1 square mm wire is 1.13mm.

- Q:How is the gold thread welded on the LED?

- The machine used for surface welding of different media, is a physical process. The first end must first wire processed to form spherical (this machine adopts electronic negative pressure into the ball), and on the surface of metal welding to preheat treatment; then the gold ball joint action in time and pressure, plastic the deformation in the welding metal surface, the two types of media to achieve a reliable contact, and the friction between the two kinds of ultrasonic vibration, the metal atoms in atomic affinity formed under the action of metal bonding, welding wire bonding is realized. The welding wire ball welding is better than in the Ridong electrical properties and applications on silicon aluminum wire, but due to welding for the precious metal must be heated, the application scope is relatively narrow.

- Q:How to remove the black dirt in the iron pan?

- Brine method. Put a little salt in the pot, add water to boil, then turn off the fire. When the water temperature is down, wipe the bottom with a steel ball. The black dirt is easy to clean.

- Q:How to choose argon arc welding machine?

- The four wheel double drive high precision wire feed mechanism should be selected, and the wire should be sent in the closed state. Because the wire plate is exposed outside, the dirt or other dirt can easily enter the slot of the feeding wheel along with the welding wire, and the welding wire is easy to slip.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

aluminium wires AA1050 with high purity and low price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products