Aluminium Sheets for Semi-Unitized Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Sheets for Semi-Unitized Curtain Wall

Aluminium Sheets for Semi-Unitized Curtain Wall are one type of non-frame curtain wall than consist of glass panels, point-fixing components on such panels and their supporting structures. .

Aluminium Sheets for Semi-Unitized Curtain Wall are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc.

2.Main Features of Aluminium Sheets for Semi-Unitized Curtain Wall

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

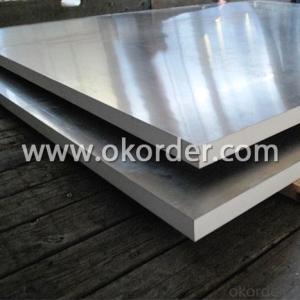

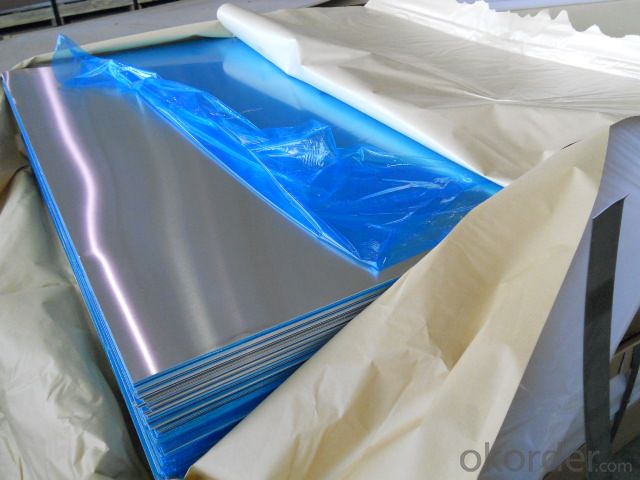

3. Aluminium Sheets for Semi-Unitized Curtain Wall Images

4.Specification of Aluminium Sheets for Semi-Unitized Curtain Wall

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:How does the surface roughness affect the friction properties of aluminum sheet?

- The surface roughness of an aluminum sheet affects its friction properties by increasing the surface area in contact with another object, leading to higher frictional forces. A rougher surface will have more irregularities and asperities, creating more points of contact and interlocking with the opposing surface. This increased contact area enhances the adhesion between the surfaces, resulting in higher friction. Conversely, a smoother surface with fewer irregularities will have reduced contact area and less adhesion, leading to lower friction.

- Q:just bought a hobart handler 140 (already love it), and was just wondering on what gas to use for aluminum. my welder will be set up for mild steel (75% argon 25% CO2). it would be nice to be able to use this mix with aluminum as well, as it would be easy to just switch spools of wire, but the manual says to use a 100% argon mix when welding with aluminum. will the 25% CO2 make a difference welding aluminum?

- You MUST use 100% Ar for MIG welding aluminum. Molten Al is highly reactive. Al powder is the active ingredient in thermite, for example. It will react with CO2, stripping away the oxygen and creating a nasty mess. Also, you really need a MIG welder with twice as much current output. along the lines of 200-300 amps. 130 amps will not perform well even with a spool gun, and running the weak, prone-to-jamming .030 Al wire. You could try to do it that way, but I would not advise. (There is no way in hell you'd be able to cram wimpy .030 Al wire through a 6 foot traditional welding lead. It'll kink and jam after 5 seconds.) MIG welding aluminum REQUIRES using the high-current, high feed speed, spray transfer mode. Here are some typical parameters: 030 wire, 500 IPM, 22 volts. 120-130 amps. 035 wire, 500 IPM, 23 volts, 150 amps. 045 wire, 400 IPM, 24 volts, 200 amps. EDIT, the guy above me has the right idea. They use electricity to force the reaction between aluminum oxide (dissolved in cryolite) and carbon, producing molten Al and CO2 gas. Normally the reaction would tend to go the other way. Aluminum has a higher affinity for oxygen.

- Q:Can aluminum sheets be used for elevator interiors?

- Yes, aluminum sheets can be used for elevator interiors. Aluminum is a commonly used material in elevator construction due to its durability, lightweight nature, and aesthetic appeal. It provides a sleek and modern look to elevator interiors while also offering high resistance to corrosion and wear.

- Q:Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used for reflective insulation. Aluminum is highly reflective and has good thermal conductivity, making it an excellent choice for reflecting heat and reducing heat transfer. When used as insulation, aluminum sheets can reflect heat away from the surface, preventing it from entering or escaping the desired area. This can help in maintaining a comfortable temperature inside a building or protecting sensitive equipment from extreme heat or cold. Additionally, aluminum sheets are lightweight and easy to install, making them a popular choice for reflective insulation applications.

- Q:write a balanced equation for the reaction between aluminium metal and potassium hydroxide in water

- Hi there! So you're given Aluminum metal, which has the oxidation state (almost always) of 3+. In play are: Al 3+ K+ OH- You have KOH(aq) + Al 3+ and they react to form a precipitate, creating Al(OH)3 and the potassium cation disperses into solution. In traditional symbols: 3 KOH (aq) + Al 3+(s) ----- Al(OH)3(s) + 3K+ (aq) That's 3 K+, 3 OH-, and 1 Al 3+. That carries for both sides! NIE would look like: 3 OH- + Al 3+ ----- Al(OH)3 (s) Most instructors don't mind if you leave off (aq) but pretty much all of them care about (s), so make sure you add those phase states! I hope I helped :)

- Q:Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties, making it a popular choice for marine applications. It forms a protective oxide layer that prevents further corrosion, making it durable and long-lasting in saltwater environments.

- Q:Are aluminum sheets prone to warping?

- Yes, aluminum sheets can be prone to warping under certain conditions. Aluminum is a relatively soft metal, meaning it is more susceptible to bending or distorting compared to other metals like steel. However, the extent to which aluminum sheets warp depends on various factors such as the thickness of the sheet, the specific alloy used, the temperature it is exposed to, and the level of stress applied to it. Thinner aluminum sheets are generally more prone to warping as they have less structural integrity. Thicker sheets, on the other hand, are more resistant to warping due to their increased rigidity. Additionally, the specific alloy composition of the aluminum sheet can influence its susceptibility to warping. Temperature fluctuations can also cause aluminum sheets to warp. When exposed to high temperatures, aluminum expands, and if not properly supported or restrained, it may bend or warp. Similarly, rapid cooling can cause contraction, resulting in warping. Lastly, the level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can cause the sheet to deform. To minimize warping, it is important to handle aluminum sheets with care, support them adequately during temperature changes, and avoid applying excessive stress. Additionally, using thicker aluminum sheets or choosing certain alloys with higher tensile strength can help mitigate the risk of warping.

- Q:Can the aluminum sheets be used for manufacturing heat sinks?

- Aluminum sheets are capable of being utilized in the production of heat sinks. Owing to its exceptional thermal conductivity features, aluminum is a favored option for heat sinks. It possesses lightweight properties, exhibits high electrical conductivity, and can be easily machined, rendering it an ideal substance for dissipating heat from electronic components. The malleability of aluminum sheets permits them to be effortlessly shaped, cut, and molded into the desired heat sink design, facilitating effective heat transfer and dissipation. Furthermore, aluminum is resistant to corrosion, which guarantees the enduring and dependable performance of the heat sink. In summary, aluminum sheets are widely employed in the manufacturing of heat sinks for a variety of applications across industries such as electronics, automotive, and aerospace.

- Q:why could aluminum pot be repaired by knocking the aluminum sheet into the pot but not being bonded by glue?

- the oxidation rate of aluminum's surface is very quick, so we cann't use the method of tin welding, and the cost of argon arc welding is very high,so aluminum pot's repair usually uses riveting. aluminum has low hardness and good ductility, so it can be repaired by tightly knocking, without the bonding of glue. general glue will decomposed in open fire, if we bond pot by glue, the pot after repair won't be able to endure high temperature.

- Q:Are aluminum sheets suitable for lightweight structures?

- Yes, aluminum sheets are suitable for lightweight structures due to their low density and high strength-to-weight ratio.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Sheets for Semi-Unitized Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords