Aluminium Sheet Plate AA3003 for Building Outside Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminium Sheet Plate AA3003 for Building Outside Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Aluminium Sheet Plate AA3003 for Building Outside Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Sheet Plate AA3003 for Building Outside Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

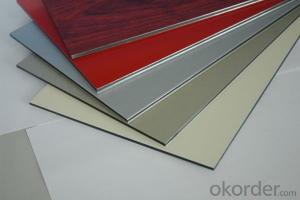

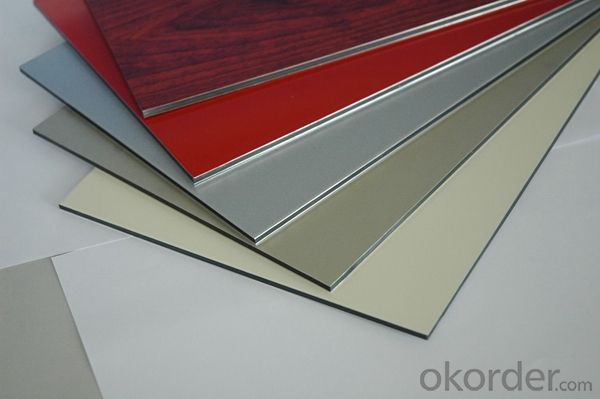

5. Image of Aluminium Sheet Plate AA3003 for Building Outside Wall

6. Package and shipping of Aluminium Sheet Plate AA3003 for Building Outside Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:How does the grain structure of aluminum sheet affect its properties?

- The grain structure of aluminum sheet significantly affects its properties. The size, shape, and orientation of the grains within the sheet determine its strength, ductility, and other mechanical properties. A fine and uniform grain structure generally results in improved strength and formability, as the smaller grains hinder crack propagation and enhance grain boundary strength. On the other hand, a coarse or uneven grain structure can weaken the sheet and make it more prone to failure. Therefore, controlling and optimizing the grain structure during manufacturing processes is crucial to achieve the desired properties in aluminum sheet.

- Q:Can 101 aluminum sheets be anodized for outdoor architectural applications?

- Yes, 101 aluminum sheets can be anodized for outdoor architectural applications. Anodizing is a process that adds a protective layer to the surface of aluminum, making it more resistant to corrosion and wear. It is commonly used for architectural applications where the aluminum needs to withstand exposure to outdoor elements. By anodizing the 101 aluminum sheets, they can be made more durable and suitable for outdoor use, ensuring that they will maintain their appearance and performance over time.

- Q:What type of aluminium sheet is a food grade?

- Pure aluminum, alloy aluminum can be. However, the majority of pure aluminum. Used by customers. You can inquire about our company: dexincheng Pioneer Metals corporation. Baidu will find the phone soon.

- Q:1mm aluminum sheet, stamping, die opening, how much is it?

- Should be cheaper, it will press a few words, such a mold seems very simple, the material does not need much good, ordinary to get itAskHow much is it? Is there a price range?Chasing the answerMore than 10000 on it, two templates, and then inserted a positioning pin, perhaps not so much moneyMore than 10000 on it, two templates, and then inserted a positioning pin, perhaps not so much money

- Q:I'm trying to use as little aluminum as possible as it can be related to health problems, and I'm just trying to be a little more careful. I just bought the Emerilware pro-clad pot and pan set, and it's stainless steel but says Emerilware Pro-Clad is constructed with an aluminum core bonded between two layers of stainless steel ideal for... Therefore, I'm still cooking with aluminum. Is it safer since it's between 2 pieces of stainless steel? Does any stainless steel cookware not use aluminum? Thanks.

- Aluminum and titanium are lighter, but they are easier to scratch (due to non-stick coatings) and do not hold heat as well. Stainless steel is more durable and distributes heat better. You can also clean it with sand or ice without having to worry about scratching it. If you are going to fry with it, you will need oil since the food will stick without it. When I go ultra light, I use a jet boil with a titanium pot to boil water for cooking. When I want to go gourmet, I use the GSI stainless steel set.

- Q:How much is the aluminum plate with a thick 2mm 1000*2000? Thanks

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q:Is aluminum sheet corrosion-resistant?

- Yes, aluminum sheet is corrosion-resistant. Aluminum forms a protective oxide layer on its surface when exposed to oxygen in the air, which helps prevent further corrosion. This oxide layer acts as a barrier, protecting the underlying metal from moisture, chemicals, and other corrosive elements. Additionally, aluminum has a high resistance to corrosion caused by saltwater, making it a popular choice for marine applications. However, it is important to note that certain conditions, such as exposure to acidic or alkaline environments, can still cause corrosion on aluminum surfaces if not properly maintained or protected.

- Q:Can 101 aluminum sheets be stamped or engraved?

- Yes, 101 aluminum sheets can be stamped or engraved. Aluminum is a versatile material that can be easily manipulated using various techniques. Stamping involves pressing a design or pattern onto the surface of the aluminum sheet, while engraving involves cutting or incising a design into the sheet. Both processes can be performed on aluminum sheets, including those made of 101 aluminum alloy. However, it is important to consider the thickness and hardness of the sheets, as these factors may affect the quality and clarity of the stamped or engraved design.

- Q:Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Aluminum is a versatile material that can be easily manipulated into different shapes and forms, making it ideal for various architectural applications. It is commonly used for exterior cladding, roofing, window frames, and facades, providing a sleek and modern aesthetic to buildings. Aluminum sheets can also be used for decorative purposes, such as wall panels, art installations, signage, and furniture. The lightweight and durable nature of aluminum make it a popular choice for architects and designers looking to create visually appealing and functional structures. Additionally, aluminum is resistant to corrosion, making it suitable for both indoor and outdoor applications.

- Q:Can aluminum plate protect against radiation?

- First, the installation depends on the way, the direct aluminum plate can not, the aluminum plate must be grounded in order to play a role. The ground is connected with the earth plate, this shot to the electromagnetic wave on the aluminum plate will be aluminum absorption into electrical energy and flow to the ground, if not grounded on the other side will generate an electric field in aluminum, is directly through to the. In fact, grounding is very simple, if the installation of the use of metal screws directly contact the aluminum plate, but also with the cement wall contact, you can be grounded, although not good grounding. If the wall is a wooden board and so on, the insulating material can not, and then there is a screw, if it is used in the wall dug into the plastic sleeve also can not, because the plastic will be insulated.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Sheet Plate AA3003 for Building Outside Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords