Aluminium Sheet Embossed for Roofing Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium Sheet Embossed for Roofing Making Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Sheet Embossed for Roofing Making:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

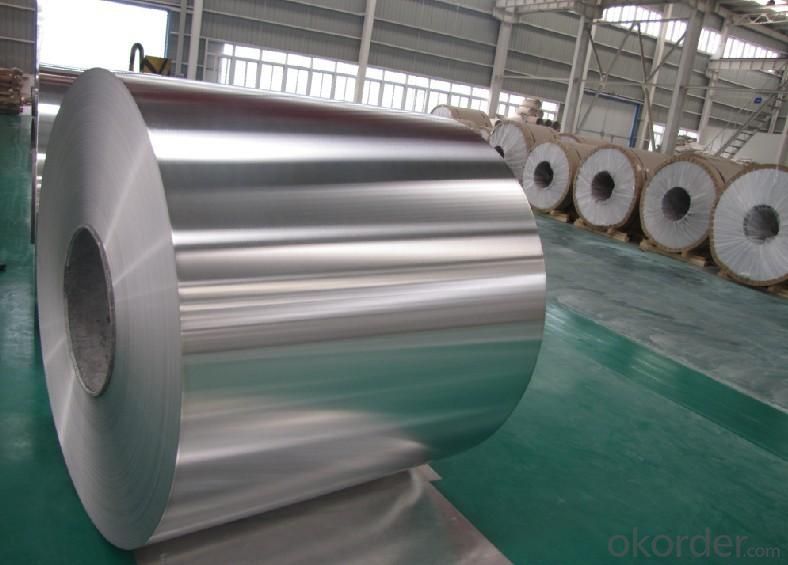

Images of the Aluminium Sheet Embossed for Roofing Making:

Aluminium Sheet Embossed for Roofing Making Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. Aluminum is a popular choice for heat shields in the automotive industry due to its excellent thermal conductivity and high heat resistance. It helps to protect sensitive components from excessive heat by reflecting and dissipating the heat away from the desired areas. Additionally, aluminum is lightweight and corrosion-resistant, making it an ideal material for automotive applications. It is commonly used in various heat shield designs, including exhaust heat shields, engine heat shields, and under-carriage heat shields.

- Q:Can aluminum sheets be used for HVAC systems?

- Yes, aluminum sheets can be used for HVAC systems. Aluminum is a popular choice for HVAC applications due to its excellent corrosion resistance, lightweight properties, and thermal conductivity. It is commonly used for manufacturing air conditioner coils, heat exchangers, ductwork, and other components in HVAC systems.

- Q:Okay guys i need to rapir a crack on an aluminum pipe , would durafix do the job ?? If so where can i get this durafix ? at my local home depot ?

- I've only found these type products online or at flea markets. It works quite well after a little practice.

- Q:What are the typical thicknesses of aluminum sheets?

- The specific application and industry requirements can cause variations in the typical thicknesses of aluminum sheets. Nevertheless, there are several standard thicknesses commonly used, including 0.025", 0.032", 0.040", 0.050", 0.063", 0.080", 0.090", 0.100", 0.125", and 0.190" inches. These thicknesses find application in diverse industries like construction, automotive, aerospace, and manufacturing. It is worth mentioning that aluminum sheets can be tailored to meet precise thickness specifications for specialized applications.

- Q:Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum has excellent thermal conductivity properties, which allows it to effectively reflect heat and prevent the transfer of thermal energy. This makes it an ideal material for insulation jackets, as it helps to maintain temperature control and minimize heat loss or gain. Additionally, aluminum sheets are lightweight, durable, and resistant to corrosion, making them a practical choice for insulation applications.

- Q:My professor gave us the following:1roll of Reynonlds Wrap Heavy Duty Aluminum18.0 in wide, 500.0 ft long and 0.94mil thickThe cost $48.98and I'm not sure how to figure it out

- length * width * thickness = volume (with some unit conversions) Mass = volume * density (look up the density of aluminum) convert mass to moles. convert moles to atoms Divide the cost by the number of Al atoms.

- Q:Can aluminum sheets handle high temperatures?

- Certainly! High temperatures are well-tolerated by aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum proves itself suitable for various applications requiring elevated temperatures. Furthermore, aluminum possesses exceptional thermal conductivity, enabling rapid heat dissipation. This attribute renders aluminum sheets ideal for deployment in environments necessitating resistance against high temperatures, including engine components, heat exchangers, and oven linings. Nevertheless, it is crucial to take into account the specific alloy and thickness of the aluminum sheet, as different alloys may impose different temperature thresholds.

- Q:Can the aluminum sheets be used for manufacturing chemical storage tanks?

- Yes, aluminum sheets can be used for manufacturing chemical storage tanks. Aluminum is corrosion-resistant and has good strength-to-weight ratio, making it suitable for storing various chemicals safely.

- Q:i bought a light fixture for my bathroom wall and the ground wire is aluminum and the existing ground wire in the wall is copper,so i would like to know if i can join them and if so,how?

- I assure you that if the light fixture was manufactured in the last 10 years, that ground wire is not aluminum. It may look aluminum but it isn't. aluminum small gauge wire for electricity has been illegal for many years. Why? It will create sparks eventually. --- So you can join that aluminum-looking ground wire to your house ground wire. (Make sure the connection is super tight - in case some nutcake put an aluminum wire for the light fixture ground) If you are still in doubt -- just replace the aluminum-looking ground wire at the fixture and replace it with a copper groung wire) btw: (aluminum is stlll allowed in heavy gauge wires from transformers to service entry panels (if they are greased at the service entry panel)

- Q:How do aluminum sheets perform in terms of flexural strength?

- Aluminum sheets generally exhibit excellent flexural strength properties. Due to their inherent structural integrity and high strength-to-weight ratio, aluminum sheets are capable of withstanding bending forces without significant deformation or failure. The flexural strength of aluminum sheets can vary depending on the alloy and temper selected, as well as the thickness of the sheet. However, in general, aluminum sheets are known to exhibit good resistance to bending and can withstand applied loads without buckling or breaking. This makes aluminum sheets suitable for various applications that require components to withstand flexural stresses, such as in the construction, automotive, aerospace, and marine industries. Additionally, aluminum sheets can be further enhanced through various fabrication techniques and alloying elements to optimize their flexural strength for specific applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Sheet Embossed for Roofing Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords