Aluminium S-profile for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium S-profile for Building Constructions Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium S-profile for Building Constructions:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

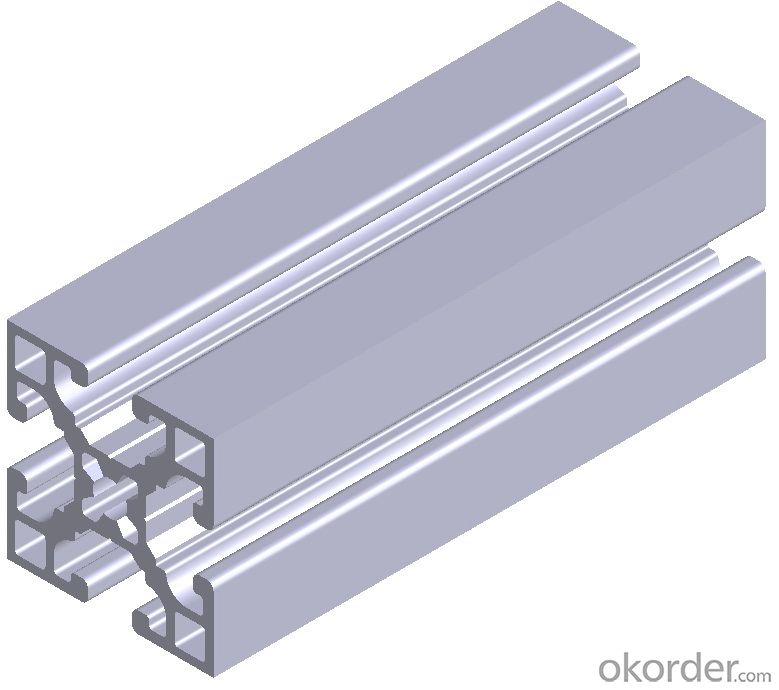

Images of theAluminium S-profile for Building Constructions:

Aluminium S-profile for Building Constructions Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:I want to make my aluminum oxide, how much money is needed is a set of equipment? Please leave, thank you!

- Aluminum oxide brand and aluminum panel process and process, please

- Q:Can aluminum profiles be used in elevator or escalator systems?

- Indeed, elevator or escalator systems can incorporate aluminum profiles. These profiles possess qualities such as being lightweight, durable, and resistant to corrosion, rendering them appropriate for a range of uses, including the construction of elevator and escalator elements. Aluminum profiles can serve as the structural framework, handrails, cladding, and other components within an elevator or escalator system. Furthermore, these profiles can be effortlessly tailored and manufactured to fulfill the exact specifications of each project. The adaptability, ratio of strength to weight, and visual attractiveness of aluminum profiles establish them as a superb option for elevator and escalator systems.

- Q:What does "T" in the aluminum profile 6063-T5 mean?

- China's current general is the United States Aluminum Association "Aluminium Association" numberT5By cooling the high temperature molding process, and then the artificial aging state. Applied by cooling high temperature molding process, not through the cold processing (for straightening and leveling, but does not affect the mechanical properties of the limit), to artificial aging products.

- Q:Are aluminum profiles suitable for use in the marine industry?

- Aluminum profiles are indeed appropriate for utilization within the marine industry due to a multitude of reasons. Firstly, aluminum possesses numerous qualities that render it an exceptional material for marine applications. Primarily, aluminum exhibits a lightweight yet robust nature, which proves vital in the construction of boats and other marine vessels. Its lightweight composition enables enhanced speeds and superior fuel efficiency. Furthermore, aluminum showcases an impressive resistance to corrosion, thus making it an ideal candidate for enduring the harsh and corrosive marine environment. This particular attribute obviates the necessity for frequent maintenance and augments the lifespan of marine structures. Moreover, aluminum boasts exceptional thermal conductivity, facilitating prompt heat dissipation and diminishing the risk of overheating in marine engines. Lastly, aluminum is highly malleable and can be effortlessly molded into diverse shapes and profiles, granting versatility in both design and construction. In conclusion, employing aluminum profiles within the marine industry guarantees a combination of strength, durability, corrosion resistance, and lightweight properties, thereby establishing it as a suitable choice for marine applications.

- Q:How do aluminum profiles contribute to sustainable infrastructure development?

- Various ways exist in which aluminum profiles contribute significantly to the promotion of sustainable infrastructure development. To begin with, aluminum, being a lightweight material, requires less energy for transportation and installation when compared to heavier materials like steel. Consequently, this reduces greenhouse gas emissions and the overall carbon footprint associated with construction projects. In addition, aluminum profiles possess exceptional durability and corrosion resistance, enabling them to withstand harsh environmental conditions and prolong the lifespan of infrastructure projects. As a result, the frequency of repairs and replacements is reduced, leading to a decrease in waste generation and resource consumption. Moreover, aluminum is a material highly amenable to recycling, as it can be recycled infinitely without losing its original properties. This fosters a circular economy by minimizing the necessity for primary aluminum production and reducing the demand for raw materials. Additionally, the recycling process for aluminum requires significantly less energy compared to primary production, resulting in decreased energy consumption and lower emissions. Furthermore, aluminum profiles offer design flexibility and compatibility with diverse construction methods, thereby permitting the implementation of innovative and sustainable infrastructure solutions. They can be readily integrated into energy-efficient systems, such as solar panels or LED lighting, to further enhance sustainability. On the whole, the incorporation of aluminum profiles in infrastructure development contributes to the creation of a more sustainable built environment by reducing energy consumption, minimizing waste generation, promoting recycling, and enabling the implementation of energy-efficient solutions.

- Q:Are aluminum profiles suitable for use in electronics manufacturing?

- Yes, aluminum profiles are suitable for use in electronics manufacturing. Aluminum is a lightweight yet durable material that offers excellent thermal conductivity, making it ideal for dissipating heat generated by electronic components. Its high strength-to-weight ratio allows for the creation of sturdy and lightweight structures, which is advantageous in electronics manufacturing where weight reduction is often desired. Additionally, aluminum profiles can be easily machined, welded, and formed into various shapes, providing flexibility in design and customization. The corrosion resistance of aluminum also ensures longevity and reliability in electronic devices. Overall, the properties of aluminum make it a suitable choice for use in electronics manufacturing.

- Q:Who can tell me the latest national standard for aluminum and the latest edition, -2008?

- Are you looking at these? These are new standards for 2008, and there are many I haven't listed. You can come here and see it. It's easy to find!Standard number: GB 5237.1-2008Standard Name: aluminium alloy construction profile first parts: base materialStandard status: not implementedEnglish Title: Wrought, aluminium, alloy, extruded, profiles, for, architecture -, Part, 1:Mill, finish, profilesAlternatives: instead of GB 5237.1-2004Date of implementation: 2009-9-1Promulgated by: China Nonferrous Metals Industry AssociationDescription: this standard specifies the lighting measuring instruments, measuring methods and measurement contents in indoor and outdoor lighting placesThis standard applies to the measurement of indoor lighting, the measurement of outdoor lighting places such as roads, squares and outdoor work areas, and the measurement of night lighting of buildingsStandard number: GB 5237.2-2008Standard Name: aluminum alloy building profile second parts: anode oxidation section

- Q:Can aluminum profiles be used in the construction of greenhouses?

- Yes, aluminum profiles can be used in the construction of greenhouses. Aluminum is a lightweight and durable material, making it an excellent choice for greenhouse construction. It is resistant to corrosion, which is important in a moist and humid environment like a greenhouse. Aluminum profiles can be easily fabricated and assembled, allowing for flexibility in design and construction. Additionally, aluminum is a sustainable material as it is 100% recyclable, making it environmentally friendly for greenhouse construction. Overall, aluminum profiles are a practical and reliable option for building greenhouses.

- Q:What are the differences between horizontal and vertical aluminum profiles?

- Horizontal vertical hanger in the middle on the head,Therefore, the horizontal number will affect the surface a little, and when you have to find non decorative surface hangingThe vertical head is better, a hanging point, just cut off

- Q:How to prevent the aging of aluminum profile hardness is not enough?

- Raw materials, alloy, cast bar qualityDuring extrusion, the outlet temperature is guaranteed to be above the solid solution temperature,Cooling, quenching speed guaranteed as fast as possible

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium S-profile for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords