Aluminium Profiles used on Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

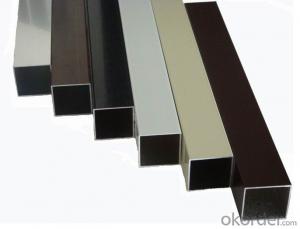

Aluminum profile

1. Brand: Bright Star

2. Place of origin: Guangdong, China

3. Temper: T5/T6

4. Grade: 6000 S

Goldsword Aluminum Factory | |

Business Type | Aluminum profile Manufacturer |

Product series | aluminum profile for window and doors |

Price Determination | Based on Aluminum Ingot Price + Process fee |

Payment Term | T/T, L/C at sight |

Surface Treatment | We can provide aluminum profiles with mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Color | We can provide white, wood color, black, golden, blue, champagne, and other colors as required. |

Packing | Composite paper, Plastic paper, other packing method required by customers is available. 2 to 20 pcs per bundle, sometimes small profiles are plugged in big ones so as to save space for customers. |

Product specification | 1. Alloy: 6063-T5/T6 2. Length: 3-6.5 m 3. Normal anodizing thickness: 8 to 12 micro 4. Normal powder coating thickness: 60 – 100 micro 5. Tensile Strength: ≥160 MPa 6. Yield strength: ≥110 MPa 7. Extensibility: ≥8% 8. Hardness (HW): ≥8 |

- Q:Are aluminum profiles suitable for the furniture industry?

- Aluminum profiles prove to be an excellent choice for the furniture industry due to their many advantages. The versatility and durability of aluminum make it a highly sought-after material for furniture manufacturing. To begin with, the lightweight nature of aluminum profiles simplifies handling and transportation, particularly for larger furniture pieces. Not only does this decrease transportation expenses, but it also enhances the user-friendliness of the furniture during installation and rearrangement. Furthermore, aluminum's remarkable resistance to corrosion ensures that furniture made with aluminum profiles can endure harsh weather conditions and maintain its durability over time. This quality makes it suitable for both indoor and outdoor furniture applications. In addition, aluminum profiles offer exceptional design flexibility. The ease with which aluminum can be extruded into various shapes and sizes allows for limitless design possibilities. This versatility facilitates the creation of customized furniture pieces that cater to specific client requirements. Moreover, the strength-to-weight ratio of aluminum profiles is commendable. Furniture constructed with aluminum becomes robust and long-lasting, which is particularly advantageous for items that experience regular use, such as chairs and tables. Additionally, aluminum is an environmentally-friendly material, as it is fully recyclable. This aligns with the increasing demand for sustainable furniture options. Manufacturers can effortlessly recycle aluminum profiles at the end of their lifecycle and employ the recycled material to fashion new furniture items, thereby reducing waste and contributing to a circular economy. In conclusion, the unique attributes of aluminum profiles make them highly fitting for the furniture industry. Their lightweight composition, resistance to corrosion, design flexibility, strength, and recyclability collectively contribute to the creation of superior-quality and sustainable furniture products.

- Q:You know, aluminum radiator, why should aluminum do?

- The biggest difference of aluminum radiator is that it has good corrosion resistance. Is due to the use of aluminum, it has the characteristics of corrosion resistance, because after aluminum in contact with oxygen, the aluminum surface to form a layer of oxide film, this layer of film to corrosion effect on the corrosion of an object. So, it's very good corrosion resistance.

- Q:What are the aluminum profile manufacturers in Jiangsu?

- For the choice of aluminum profiles, here are a few suggestions for you to refer to:First: very cheap, do not chooseAs follows: the cost of industrial aluminum material = the spot price of aluminum ingot, the processing cost of extrusion aluminum material, the freight of packing material. These are transparent, the cost of aluminum profiles are similar, significantly lower than the market price, the first possibility: the weight per meter less; second: aluminum is the use of recycled materials; third: material loss amplification (not according to the actual sales amount of meters).Second: only understand the sale material supplier does not chooseExplain as follows: preparing goods, recruit a few operator, big online promotion can be opened. Those who are often hurt are our buyers. Miss wiring mostly do not know how to use, only know the unit price. How to use to meet customer needs; how to make the most cost-effective; in different venues that kind of connection is the best; these are they can not answer accurately. Only know the cheapest and recommended profile connection the cheapest; this connection is the lowest cost, but the cost of artificial, a connection is the weakest, aluminum convenience wouldn't be reflected, and will bring much trouble for the future reconstruction. But the wiring girl will push it one way.Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, and their users have very rich experience, have a good understanding and knowledge of the quality and performance of products, suitable for the requirement of the customers will recommend price is a good product, choose a convenient and practical accessories.

- Q:Aluminum 3100-6063-T5, please

- Aluminum in the industry according to material characteristics, such as hardness, strength, corrosion resistance and other categories, there are 8 main series, each series with 4 figures as a brand, and subdivided into many types1 series industrial pure aluminum: 1XXX2 series superhard aluminum material: 2XXX3 series easy cutting aluminum material: 3XXX4 series easy cutting aluminum material: 4XXX5 series magnesium aluminum alloy: 5XXX6 series anodic oxidation and corrosion resistant aluminum: 6XXX7 Series aviation ultra hard aluminum: 7XXX8 series: 8XXXYou say 3100-6063-T5 may contain the 3 and 6 series, easy to cut and resistant to corrosion,.T5 indicates hardness levels

- Q:Are there any limitations or drawbacks of using aluminum profiles?

- Yes, there are some limitations and drawbacks of using aluminum profiles. One limitation is its lower strength compared to other materials such as steel. Aluminum profiles may not be suitable for heavy-duty applications that require high tensile strength or load-bearing capacity. Therefore, in certain scenarios, steel or other materials may be preferred. Another drawback is that aluminum is more prone to corrosion compared to materials like stainless steel. Although aluminum profiles can be treated with protective coatings, they may still be susceptible to corrosion in harsh environments or if not properly maintained. This can affect their durability and longevity. Furthermore, aluminum profiles may have higher initial costs compared to other materials. The production and processing of aluminum can be more expensive, which can impact the overall cost of using aluminum profiles in construction or manufacturing projects. Lastly, aluminum profiles may have limitations in terms of design flexibility. While aluminum is relatively easy to shape and mold into various profiles, it may not be as versatile as some other materials. This can limit the options available for complex or intricate designs. Despite these limitations and drawbacks, aluminum profiles still offer many advantages such as lightweight construction, excellent thermal conductivity, and resistance to electrical conductivity. Therefore, it is essential to carefully consider the specific requirements and constraints of a project before deciding to use aluminum profiles.

- Q:Can aluminum profiles be cut to size?

- Yes, aluminum profiles can be cut to size. Aluminum profiles are typically manufactured in standard lengths and can be easily cut to the desired length or size using various cutting methods such as sawing, shearing, or CNC machining. This allows for customization and flexibility in using aluminum profiles for different applications.

- Q:Can aluminum profiles be used in interior design applications?

- Yes, aluminum profiles can be used in interior design applications. They are versatile, lightweight, durable, and available in various finishes and designs. Aluminum profiles can be used for creating furniture, partitions, shelving, lighting fixtures, decorative elements, and more, adding a modern and sleek aesthetic to interior spaces.

- Q:What are the fire-resistant properties of aluminum profiles?

- Aluminum profiles offer a range of fire-resistant qualities that render them suitable for a variety of uses. Firstly, aluminum boasts a remarkably high melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), enabling it to endure extreme temperatures without succumbing to melting or compromising its structural integrity. Furthermore, aluminum possesses a low ignition point, necessitating a higher temperature than other metals to ignite. This attribute reduces the likelihood of aluminum catching fire when exposed to heat or flames. In the event of a fire, aluminum profiles generate a protective layer of aluminum oxide on their surface owing to their innate oxide layer. This layer acts as a barrier, impeding the propagation of flames and hindering the combustion process. Moreover, the aluminum oxide layer exhibits exceptional heat resistance, thereby providing supplementary defense against elevated temperatures. Additionally, aluminum profiles are non-combustible, meaning they do not contribute to the expansion of a fire. This characteristic assumes critical importance in ensuring fire safety by containing the fire within a specific zone and averting rapid spreading. Taken together, the fire-resistant attributes of aluminum profiles, encompassing their high melting point, low ignition point, the formation of a protective oxide layer, and non-combustibility, establish them as a dependable choice for a wide range of applications where fire safety is a paramount concern.

- Q:What are the different surface treatment options available for aluminum profiles?

- There are several surface treatment options available for aluminum profiles, each offering unique benefits and enhancing their appearance and performance. Some of the common surface treatments for aluminum profiles include: 1. Anodizing: Anodizing is a popular surface treatment method that creates a protective oxide layer on the aluminum surface. It offers excellent corrosion resistance, durability, and can be made in various colors. Anodized aluminum profiles are commonly used in architectural, automotive, and aerospace applications. 2. Powder coating: Powder coating involves applying a dry powder to the aluminum surface and then curing it with heat. This process creates a tough, decorative, and protective layer that enhances the profile's durability, scratch resistance, and weatherability. Powder-coated aluminum profiles are widely used in the construction industry due to their aesthetic appeal and resistance to fading. 3. Electrophoretic coating: Also known as electrocoating or e-coating, this process involves immersing the aluminum profile in a bath of paint and applying an electric current to deposit the paint particles uniformly. Electrophoretic coating provides excellent corrosion resistance, uniform thickness, and a smooth finish. It is commonly used in the automotive and electronics industries. 4. Mechanical finishing: Mechanical finishing techniques, such as brushing or polishing, are used to enhance the appearance and smoothness of aluminum profiles. Brushing creates a brushed or satin finish, while polishing creates a mirror-like, reflective surface. These finishes are often applied to decorative or architectural aluminum profiles. 5. Chemical etching: Chemical etching involves selectively removing material from the aluminum surface using an acid or chemical solution. This process can create decorative patterns, logos, or text on the profile's surface. Chemical etching is commonly used for branding or aesthetic purposes in various industries. 6. Plating: Plating is the process of depositing a thin layer of metal, such as chrome or nickel, onto the aluminum surface. This treatment enhances the appearance, corrosion resistance, and wear resistance of aluminum profiles. Plated aluminum profiles are often used in the automotive, electronics, and decorative industries. It's important to note that the choice of surface treatment depends on the specific requirements of the application, such as aesthetics, durability, corrosion resistance, or conductivity. Consulting with a professional or supplier can help determine the most suitable surface treatment option for aluminum profiles based on your needs.

- Q:What are the different bending radii available for aluminum profiles?

- Depending on the specific application requirements, the available bending radii for aluminum profiles can vary. However, aluminum profiles typically offer a range of bending radii options to accommodate different needs. Common bending radii for aluminum profiles include 1.5D, 2D, 3D, and 4D. In these radii, the "D" refers to the outer diameter of the profile. For instance, a 1.5D bending radius indicates that the bend radius is 1.5 times the outer diameter of the profile. The choice of bending radius depends on various factors, such as the thickness and alloy of the aluminum, the desired bending angle, and the intended application. Smaller bending radii are often employed for tighter bends or when a more compact design is necessary. Conversely, larger bending radii are suitable for gentler bends or when maintaining the structural integrity of the profile is crucial. It is important to note that the bending process can impact the mechanical properties of the aluminum profile, including its strength and stiffness. Therefore, it is crucial to carefully consider the bending radius to ensure that the profile retains its desired properties post-bending. To determine the most appropriate bending radius for a specific aluminum profile, it is advisable to seek guidance from manufacturers or experts knowledgeable in aluminum bending processes. They can offer valuable insights based on the specific requirements and limitations of the application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profiles used on Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords