Aluminium Profiles for making Solar Panel Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Aluminium Profiles for making Solar Panel Frame Description

Aluminium Profiles for making Solar Panel Frame is one semi-finished aluminium material. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Profiles for making Solar Panel Frame

Aluminium Profiles for making Solar Panel Frame | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Profiles for making Solar Panel Frame

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Profiles for making Solar Panel Frame

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Profiles for making Solar Panel Frame

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

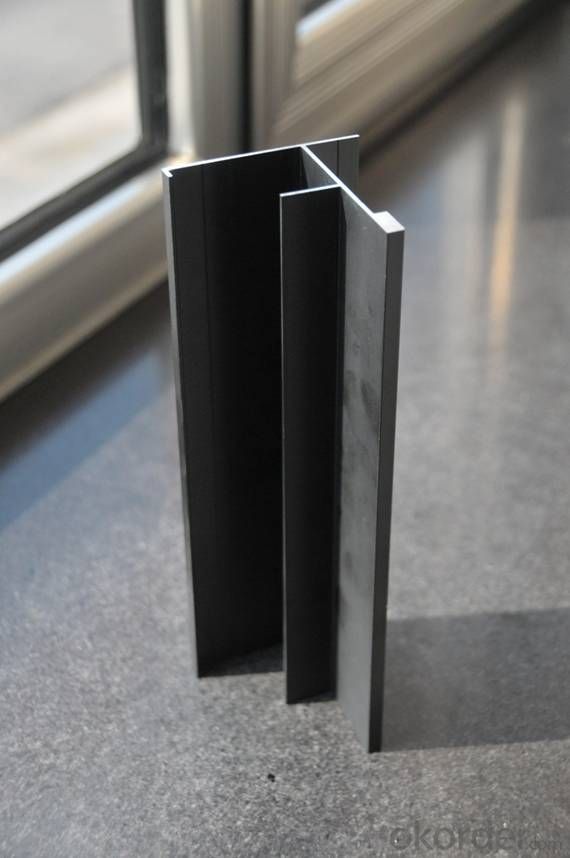

6. Image of Aluminium Profiles for making Solar Panel Frame

7. Package and shipping of Aluminium Profiles for making Solar Panel Frame

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:How do aluminum profiles perform in terms of UV resistance?

- Good UV resistance is typically offered by aluminum profiles. Protection against UV radiation is provided to some extent by the natural oxide layer that forms on the surface of aluminum. However, the UV resistance performance of aluminum profiles can vary depending on factors like the specific alloy used, the quality of surface treatment, and the environmental conditions to which they are exposed. Alloys with higher copper content, such as 6000 series aluminum, generally have better UV resistance compared to pure aluminum or alloys with lower copper content. This is because copper enhances the ability of the natural oxide layer to withstand UV radiation. Proper anodizing or powder coating processes tend to improve the UV resistance of aluminum profiles in terms of surface treatment. Anodizing involves the creation of a thicker and more durable oxide layer on the surface of the aluminum, enhancing its ability to resist UV damage. On the other hand, powder coating involves the application of a protective polymer layer to the aluminum surface, acting as a barrier against UV radiation. The UV resistance of aluminum profiles can also be influenced by environmental conditions. Intense sunlight, high temperatures, and exposure to pollutants or corrosive substances can accelerate the degradation of the oxide layer, thereby reducing overall UV resistance. Regular cleaning and maintenance can help extend the lifespan and UV resistance of aluminum profiles. To summarize, aluminum profiles generally offer good UV resistance due to the presence of a natural oxide layer on the surface. The performance in terms of UV resistance can be influenced by factors such as alloy composition, surface treatment, and environmental conditions. It is advisable to consult manufacturers or suppliers to ensure that the specific aluminum profiles meet the required UV resistance for the intended application.

- Q:Fenglv aluminum material how ah? What aluminum materials do you use for windows and doors?

- Economic point of view, choose plastic film packaging materials. Yes, the price of the material must be more expensive, at one price per share.

- Q:Can aluminum profiles be used for modular storage systems?

- Yes, aluminum profiles can definitely be used for modular storage systems. Aluminum is a lightweight yet sturdy material that is commonly used in various industries for its durability and versatility. It is particularly well-suited for modular storage systems due to its ability to be easily cut, shaped, and joined together. Aluminum profiles provide a great solution for creating customized storage units that can be easily adjusted or expanded as needed. They can be used to build shelving systems, cabinets, drawers, and other storage components. The modular design allows for easy assembly and disassembly, making it convenient to rearrange or reconfigure the storage system whenever required. Furthermore, aluminum profiles offer excellent corrosion resistance, ensuring that the storage system will remain in good condition even in harsh environments. They are also available in a variety of finishes, allowing for customization to match the desired aesthetic or design requirements. Overall, aluminum profiles provide a cost-effective and durable solution for modular storage systems, offering flexibility, ease of use, and long-lasting performance.

- Q:Are aluminum profiles easy to install?

- Aluminum profiles, in general, have a reputation for being easy to install. Their lightweight nature and manipulability contribute to a simpler installation process when compared to alternative materials. Moreover, aluminum profiles frequently come equipped with pre-drilled holes or slots, which aid in installation and guarantee precise alignment. Additionally, the modular design of aluminum profiles permits effortless assembly and disassembly without any requirement for specialized tools or expertise. All in all, the user-friendly characteristics of aluminum profiles make them a favored option for a wide range of applications, including construction, manufacturing, and DIY projects.

- Q:Are aluminum profiles suitable for modular construction?

- Yes, aluminum profiles are highly suitable for modular construction. They are lightweight, yet strong and durable, making them ideal for creating modular structures. Aluminum profiles are easy to fabricate and can be easily assembled or disassembled, allowing for flexibility in design and construction. Additionally, aluminum is resistant to corrosion, which ensures the longevity of the modular construction.

- Q:Can aluminum profiles cross Luo? Why is the appearance of an aluminum profile component of a Japanese original machine extremely close to that of Luo Luo? Why? Why?

- The company since its establishment, relying on preferential policies, the local government to adhere to the people-oriented, development of the concept of Societe Generale, seek survival by quality, rely on the brand to expand the market, seize the opportunity, innovation, build a pragmatic and efficient, solidarity of the modern enterprise team.Luoyang is located in the Central Plains, is a famous industrial base, its energy and resource advantages, a strong industrial base, research institutes everywhere, has created favorable conditions for the development of the aluminum industry of new and high technology, coupled with the current domestic and foreign aluminum demand is far greater than the output of this special factors, provides a good opportunity for the more the project, the project prospects for a broader market.

- Q:Can aluminum profiles be used in the construction of modular healthcare facilities?

- Indeed, the utilization of aluminum profiles is viable for the development of modular healthcare facilities. Due to their lightweight nature, durability, and exceptional structural properties, aluminum profiles prove to be an excellent option for the construction of such facilities. The ease with which these profiles can be fabricated and assembled allows for swift and efficient construction of healthcare modules. Furthermore, aluminum possesses corrosion resistance, a crucial characteristic in healthcare facilities where hygiene is of utmost importance. Additionally, aluminum exhibits commendable thermal and electrical conductivity, enabling efficient energy management and the integration of diverse electrical systems within the modular healthcare facility. Ultimately, aluminum profiles present numerous advantages and are a fitting material choice for the construction of modular healthcare facilities.

- Q:Industrial aluminum profiles are generally used in what industry?

- Kunshan Austrian crown aluminum to tell you: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, electronic machinery industry and clean room with.

- Q:How do you ensure proper electrical grounding with aluminum profiles?

- To ensure proper electrical grounding with aluminum profiles, there are a few key steps that need to be followed. Firstly, it is important to ensure that all aluminum profiles are clean and free from any dirt, dust, or oxidation. This can be achieved by using a suitable cleaning agent or solvent to remove any contaminants that may hinder the grounding process. Next, proper electrical grounding can be achieved by using conductive hardware such as grounding clips or brackets specifically designed for aluminum profiles. These hardware components should be securely attached to the aluminum profiles, ensuring a reliable electrical connection. Additionally, it is crucial to establish a solid electrical connection between the aluminum profiles and the grounding system. This can be achieved by using copper or aluminum grounding conductors that are properly sized and securely connected to both the aluminum profiles and the grounding system. Furthermore, it is important to regularly inspect the grounding system to ensure its effectiveness. This can involve checking for any loose connections, signs of corrosion, or damage to the grounding conductors. Any issues should be promptly addressed and repaired to maintain proper electrical grounding. Lastly, it is recommended to consult with a qualified electrician or engineer who specializes in electrical grounding when working with aluminum profiles. They can provide specific guidance and ensure compliance with relevant electrical codes and standards to ensure proper and safe electrical grounding.

- Q:Are aluminum profiles suitable for use in aerospace structural components?

- Yes, aluminum profiles are suitable for use in aerospace structural components. Aluminum is a lightweight and strong material, making it an ideal choice for aerospace applications where weight reduction is crucial. It offers high strength-to-weight ratio, excellent corrosion resistance, and good formability, allowing for the fabrication of complex shapes and structures. Additionally, aluminum profiles can be easily joined using various techniques such as welding, riveting, or adhesive bonding, making them versatile for the assembly of aerospace structural components. Overall, the combination of its properties and ease of manufacturing make aluminum profiles a suitable choice for use in aerospace structural components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profiles for making Solar Panel Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords