Aluminium Profile to Make Doors and Windows 6063 Alloy T5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminium Profile to Make Doors and Windows 6063 Alloy T5 Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile to Make Doors and Windows 6063 Alloy T5 :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

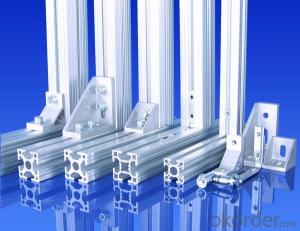

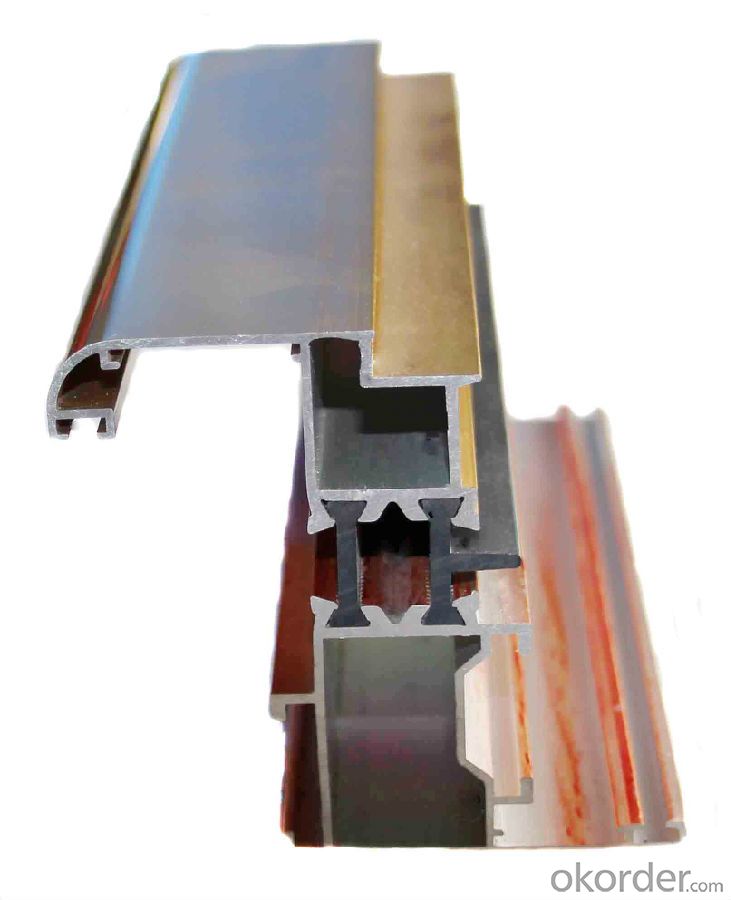

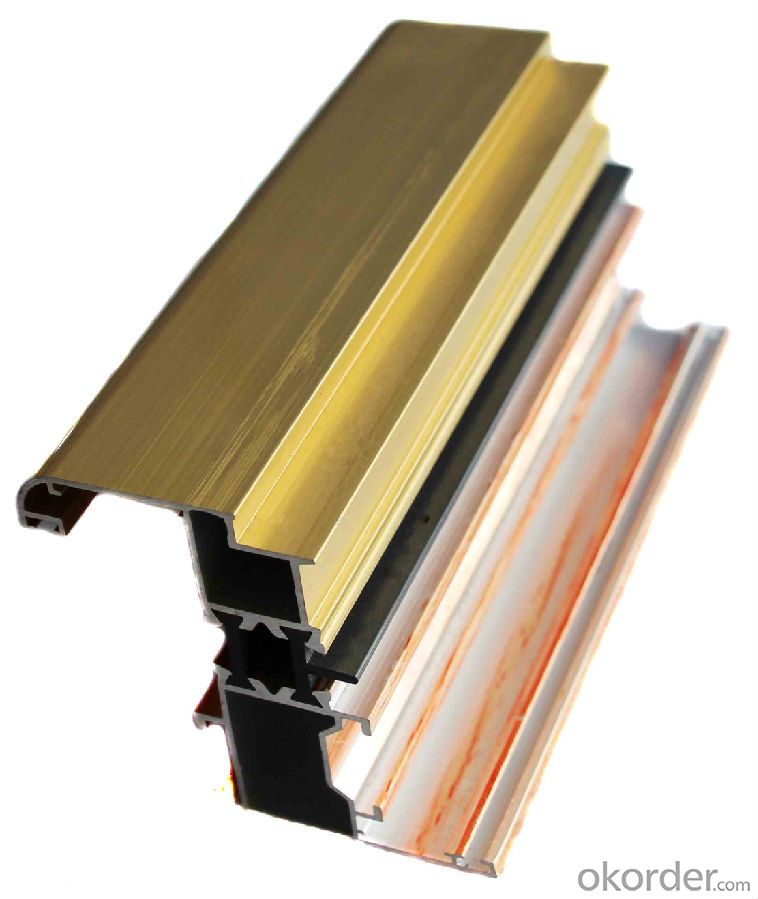

3.Aluminium Profile to Make Doors and Windows 6063 Alloy T5 Images:

4.Aluminium Profile to Make Doors and Windows 6063 Alloy T5 Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What are the different shapes and sizes of aluminum profiles available?

- A diverse selection of shapes and sizes of aluminum profiles are accessible to accommodate different industrial and architectural needs. Some frequently encountered shapes of aluminum profiles comprise: 1. T-shape: These profiles possess a T-shaped cross-section, consisting of a horizontal top and a vertical stem. They are commonly utilized in framing and structural applications. 2. U-shape: U-shaped profiles exhibit a U-shaped cross-section, featuring two parallel horizontal arms and a connecting vertical stem. They are often employed as edge trims or decorative moldings. 3. L-shape: L-shaped profiles display a right-angle cross-section, with one arm longer than the other. They are frequently used as brackets or corner guards. 4. Square: Square profiles exhibit equivalent width and depth, resulting in a square-shaped cross-section. They offer versatility and can be applied for various purposes, such as frames, supports, or enclosures. 5. Rectangular: Rectangular profiles possess unequal width and depth, forming a rectangular cross-section. They are commonly utilized for structural intentions, like beams or frames. 6. Round: Round profiles showcase a circular cross-section and are commonly employed for applications necessitating a curved or smooth finish, such as handrails or decorative elements. Furthermore, aluminum profiles are obtainable in an assortment of sizes, ranging from diminutive dimensions suitable for lightweight applications to larger sizes for heavy-duty usage. The measurements of aluminum profiles are determined by their width, depth, and thickness, which can be personalized based on specific project requirements. In summary, the broad range of shapes and sizes of aluminum profiles allows for adaptability and versatility in design and construction, ensuring the availability of an appropriate profile for every application.

- Q:Aluminum 3100-6063-T5, please

- Aluminum in the industry according to material characteristics, such as hardness, strength, corrosion resistance and other categories, there are 8 main series, each series with 4 figures as a brand, and subdivided into many types1 series industrial pure aluminum: 1XXX2 series superhard aluminum material: 2XXX3 series easy cutting aluminum material: 3XXX4 series easy cutting aluminum material: 4XXX5 series magnesium aluminum alloy: 5XXX6 series anodic oxidation and corrosion resistant aluminum: 6XXX7 Series aviation ultra hard aluminum: 7XXX8 series: 8XXXYou say 3100-6063-T5 may contain the 3 and 6 series, easy to cut and resistant to corrosion,.T5 indicates hardness levels

- Q:Are aluminum profiles suitable for use in the mining industry?

- Yes, aluminum profiles are suitable for use in the mining industry. Aluminum is a lightweight, yet strong and durable material that offers numerous advantages for mining applications. One key advantage of aluminum profiles is their excellent corrosion resistance. In the mining industry, where equipment is often exposed to harsh environmental conditions and chemicals, this corrosion resistance is crucial. Aluminum profiles can withstand exposure to moisture, chemicals, and other corrosive substances without deteriorating, ensuring long-lasting performance and reducing maintenance costs. Another benefit of aluminum profiles is their high strength-to-weight ratio. Aluminum is significantly lighter than other metals commonly used in mining equipment, such as steel. This lightweight characteristic makes aluminum profiles easier to handle, transport, and install, saving time and labor costs. Despite its lightweight nature, aluminum profiles are still strong enough to withstand the demanding conditions of the mining industry, making them a reliable choice for various applications. Additionally, aluminum profiles offer excellent thermal conductivity. This property is advantageous in mining operations that involve heat-generating machinery or processes. Aluminum profiles can efficiently dissipate heat, preventing equipment overheating and enhancing overall safety and productivity. Furthermore, aluminum is a non-magnetic material, making it ideal for mining operations that require non-magnetic equipment. This characteristic ensures that aluminum profiles will not interfere with sensitive equipment or disrupt magnetic fields, maintaining the accuracy and reliability of mining processes. In summary, aluminum profiles are highly suitable for use in the mining industry due to their corrosion resistance, high strength-to-weight ratio, thermal conductivity, and non-magnetic properties. Using aluminum profiles in mining equipment can enhance performance, reduce maintenance costs, and improve overall efficiency in various mining applications.

- Q:I am a mold professional, in school are mainly plastic mold and stamping die, but I am now in an aluminum extrusion die master apprentice. Draw pictures every day and walk around the workshop. But I have never met any related knowledge before, and I don't know where to start. I don't know what to do. Sometimes even want to give up, but not reconciled. I hope you can give me some advice. Thank you very much!!!

- 1, to let them die factory processing, mold design they figure, their wages are high, so I want to learn, do not know where to start, buy a book, the mold design of aluminum extrusion, want to learn to know the properties of extrusion machine, structure;2, according to the experience, to a step by step to produce aluminum profile extrusion die to meet the size requirements, first of all to ensure the uniformity of metal flow and extrusion out of the heart often Youao phenomenon, cause the surface subsidence, the flatness is not standard, through a lot of practice conclusion.

- Q:What are the different types of gaskets used with aluminum profiles?

- Aluminum profiles commonly utilize various types of gaskets. Let's explore a few examples: 1. EPDM Gaskets: Crafted from a synthetic rubber material, EPDM gaskets excel in withstanding weathering, UV radiation, and ozone exposure. They are frequently employed in outdoor scenarios that demand a secure seal and resilience against harsh environmental conditions. 2. Silicone Gaskets: Renowned for their exceptional temperature resistance, silicone gaskets are a preferred option for applications involving extreme heat or cold. They also exhibit favorable resistance to chemicals and UV radiation, rendering them suitable for a wide array of industrial and commercial uses. 3. PVC Gaskets: Composed of a plastic material, PVC gaskets are extensively used due to their remarkable resistance to chemicals, oil, and moisture. They commonly find application in situations necessitating a tight seal, such as doors, windows, and architectural uses. 4. Neoprene Gaskets: Neoprene gaskets are constructed from a synthetic rubber material that offers commendable resistance to oils, chemicals, and weathering. They are frequently employed in machinery and equipment, where both sealing and vibration dampening are required. 5. Nitrile Gaskets: Nitrile gaskets, also known as Buna-N gaskets, are composed of a synthetic rubber material that boasts outstanding resistance to oils, fuels, and solvents. They find common use in automotive and industrial settings where resistance to oil and fuel is critical. These examples are merely a snapshot of the diverse gasket options available for aluminum profiles. The choice of gasket hinges upon the specific requirements of the application, encompassing desired sealing level, environmental conditions, and chemical compatibility.

- Q:How do you prevent warping or distortion of aluminum profiles during fabrication?

- To prevent warping or distortion of aluminum profiles during fabrication, several measures can be taken. Firstly, it is important to ensure that the profiles are properly stored and handled before fabrication, avoiding any bending or twisting. During the fabrication process, maintaining consistent and controlled heat is crucial. This can be achieved through proper temperature regulation and using appropriate welding techniques. Additionally, employing fixtures or jigs to hold the profiles in place during fabrication can minimize any potential warping. Lastly, allowing sufficient cooling time after welding or machining processes can help alleviate any residual stress that may lead to warping.

- Q:What is the difference between 6063-T5 and 6061-T6 aluminum profiles?

- At present, microstructure and mechanical properties of joint changes have some preliminary research on the welding of 6000 Aluminum Alloy, Department of the welding joint part of the alloy softening phenomenon is more serious, the main reason is the influence of softening joint welding thermal cycle of reinforcement particles occurred in aging and coarsening. The above research mainly concentrated in the softening behavior of welding, microstructure and heat affected zone of alloy, but on the 6063 Aluminum Alloy changes the mechanical properties of welding joints and welding thermal cycle and the relationship between the effect of artificial aging is also a lack of detailed research. The T5 condition is aging and natural cooling! The coefficient of deformation is small and easy to control! General hardness! T6 status is water cooled! Large coefficient of deformation! Not easy to control! High hardness!

- Q:What are the features of the poor aluminum profiles?

- Low precision, bad feel, and so on, some inferior shape.You'd better go to the manufacturer you trust.

- Q:Who can tell me the latest national standard for aluminum and the latest edition, -2008?

- Are you looking at these? These are new standards for 2008, and there are many I haven't listed. You can come here and see it. It's easy to find!Standard number: GB 5237.1-2008Standard Name: aluminium alloy construction profile first parts: base materialStandard status: not implementedEnglish Title: Wrought, aluminium, alloy, extruded, profiles, for, architecture -, Part, 1:Mill, finish, profilesAlternatives: instead of GB 5237.1-2004Date of implementation: 2009-9-1Promulgated by: China Nonferrous Metals Industry AssociationDescription: this standard specifies the lighting measuring instruments, measuring methods and measurement contents in indoor and outdoor lighting placesThis standard applies to the measurement of indoor lighting, the measurement of outdoor lighting places such as roads, squares and outdoor work areas, and the measurement of night lighting of buildingsStandard number: GB 5237.2-2008Standard Name: aluminum alloy building profile second parts: anode oxidation section

- Q:What are the surface hardness properties of aluminum profiles?

- The surface hardness properties of aluminum profiles can vary depending on the specific alloy and treatment processes applied. Aluminum alloys are generally known for having a lower hardness compared to other metals such as steel. However, through various treatments, aluminum profiles can achieve improved surface hardness. One common treatment method is anodizing, which involves creating an oxide layer on the surface of the aluminum. This process not only enhances the corrosion resistance of the profiles but also increases their surface hardness. Anodized aluminum profiles can have a hardness ranging from 150 to 300 HV (Vickers hardness), depending on the thickness of the oxide layer. Another treatment process is hard coating, where a ceramic material such as aluminum oxide is applied to the surface of the profiles. This coating significantly enhances the hardness of the aluminum, providing a greater level of wear resistance. The hardness of hard-coated aluminum profiles can range from 400 to 600 HV or even higher. It is important to note that the specific hardness properties can vary depending on the alloy composition, surface treatment method, and the desired application of the aluminum profiles. Therefore, it is crucial to consult with manufacturers or suppliers to determine the appropriate hardness properties that best suit your specific needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile to Make Doors and Windows 6063 Alloy T5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords