Aluminium Profile of Casting Material for Windows

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminium Profile of Casting Material for Windows Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile of Casting Material for Windows:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

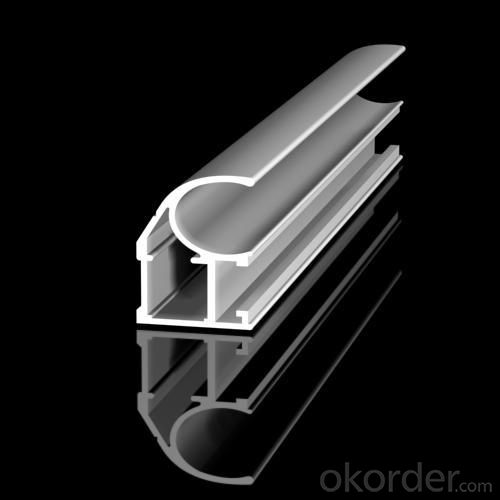

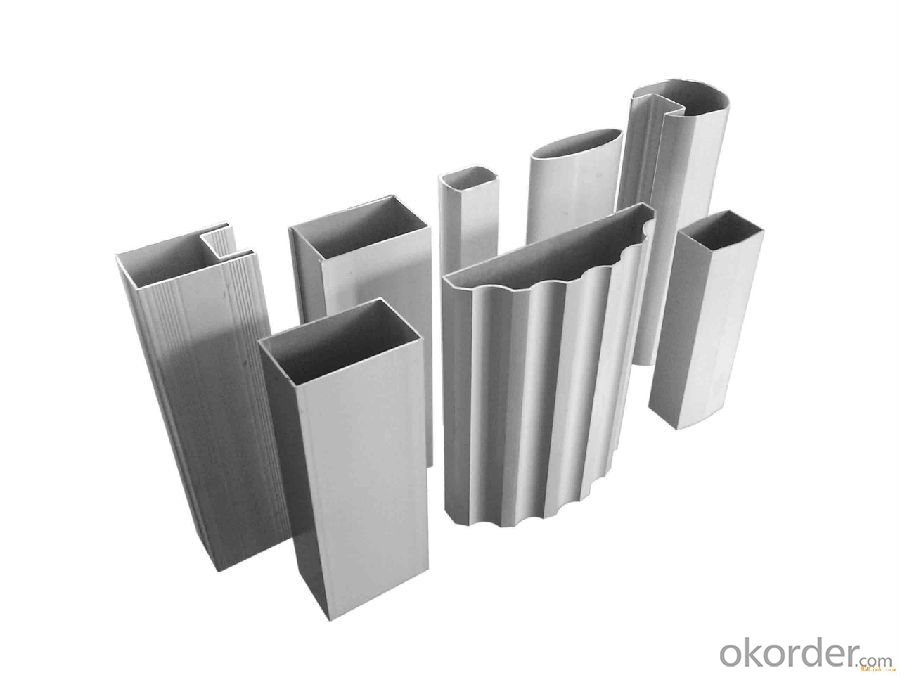

3.Aluminium Profile of Casting Material for Windows Images:

4.Aluminium Profile of Casting Material for Windows Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Can aluminum profiles be used in green building projects?

- Green building projects can utilize aluminum profiles effectively. Aluminum, being an eco-friendly material, offers numerous advantages in the realm of green building. To begin with, aluminum's lightweight nature cuts down on transportation costs and energy consumption during construction. Furthermore, aluminum is entirely recyclable, ensuring that it can be reused indefinitely without any loss in quality. This characteristic makes aluminum an ideal option for green building projects as it aids in waste reduction and promotes a circular economy. Additionally, aluminum boasts a lengthy lifespan and necessitates minimal upkeep, further enhancing its sustainability. It is worth noting that aluminum profiles can easily be integrated with other green building materials like glass, enabling energy-efficient designs that maximize natural light and minimize the reliance on artificial lighting. In conclusion, aluminum profiles offer a sustainable and versatile choice for green building projects.

- Q:How do aluminum profiles compare to other materials used for construction and manufacturing?

- Aluminum profiles offer numerous advantages compared to other materials used in construction and manufacturing. Firstly, aluminum is lightweight yet strong, making it easier to handle and transport while maintaining structural integrity. Additionally, aluminum profiles are highly corrosion-resistant, making them suitable for outdoor and marine applications. Furthermore, aluminum is non-combustible, providing a significant safety advantage. Moreover, aluminum profiles are versatile and can be easily customized to meet specific design requirements. Lastly, aluminum is highly recyclable, making it a sustainable choice for environmentally conscious projects.

- Q:What are the vibration damping properties of aluminum profiles?

- Aluminum profiles have excellent vibration damping properties. Due to their high stiffness-to-mass ratio, aluminum profiles effectively absorb and dissipate vibrations, reducing their magnitude and preventing their transmission to surrounding structures. This property makes aluminum profiles ideal for applications where vibration control is critical, such as in the aerospace, automotive, and construction industries. The inherent damping characteristics of aluminum profiles help in minimizing noise, minimizing wear and tear, and ensuring structural integrity. Additionally, aluminum's ability to dampen vibrations also enhances the overall comfort and safety of various products and structures.

- Q:What are the different types of aluminum alloys used for profiles?

- There are several different types of aluminum alloys used for profiles, including 6061, 6063, and 7075. These alloys offer varying levels of strength, corrosion resistance, and machinability, making them suitable for different applications. 6061 is a commonly used alloy for general structural purposes, while 6063 is often used for architectural and decorative applications due to its excellent finishing properties. On the other hand, 7075 is a high-strength alloy primarily used in aerospace and high-performance applications.

- Q:Are aluminum profiles suitable for solar panel frames?

- Solar panel frames made from aluminum profiles are an excellent option. Aluminum is a lightweight material that is also strong, making it perfect for constructing solar panel frames. It offers exceptional resistance to corrosion, which is crucial for outdoor use, ensuring that the frames last a long time. Additionally, aluminum profiles can be easily shaped and formed, allowing for flexible and customizable designs that can accommodate various solar panel sizes and configurations. Moreover, aluminum is highly sustainable as it is completely recyclable, aligning with the environmentally-friendly nature of solar energy. In summary, using aluminum profiles for solar panel frames provides numerous benefits such as strength, durability, corrosion resistance, flexibility, and sustainability, making it an extremely suitable choice.

- Q:Can aluminum profiles be used for creating lightweight furniture?

- Indeed, lightweight furniture can be fashioned using aluminum profiles. Given its lightweight and durable nature, aluminum proves to be an optimal choice for furniture design when weight is a factor to be taken into account. The malleability of aluminum profiles allows for their transformation into an assortment of furniture elements, including frames, legs, and supports. Moreover, the corrosion resistance offered by aluminum profiles is highly advantageous for furniture intended for outdoor or moisture-exposed environments. The adaptability of aluminum profiles enables the conception of elegant and contemporary furniture designs that not only possess a feather-light quality but also possess an aesthetically appealing allure.

- Q:Can aluminum profiles be used in HVAC systems?

- Yes, aluminum profiles can be used in HVAC systems. Aluminum is a lightweight and durable material that is commonly used in various industries, including HVAC. It offers several advantages such as excellent thermal conductivity, corrosion resistance, and easy formability. Aluminum profiles are commonly used in HVAC systems for components such as ductwork, air vents, and heat exchangers. Ductwork made from aluminum profiles is lightweight, easy to install, and resistant to corrosion, making it a popular choice for HVAC installations. Aluminum air vents provide efficient airflow and can be easily adjusted to control the direction and volume of air. Aluminum heat exchangers are also widely used in HVAC systems. The excellent thermal conductivity of aluminum allows for efficient heat transfer, making it ideal for applications where heat exchange is necessary. Additionally, aluminum's corrosion resistance ensures the longevity and reliability of heat exchangers, even in harsh environments. Overall, aluminum profiles are a suitable choice for HVAC systems due to their lightweight nature, durability, thermal conductivity, and corrosion resistance. They contribute to the overall efficiency and performance of HVAC systems while ensuring long-lasting functionality.

- Q:Are aluminum profiles suitable for electrical grounding applications?

- Yes, aluminum profiles are suitable for electrical grounding applications. Aluminum is a highly conductive material that allows for efficient flow of electrical current, making it an ideal choice for grounding systems. Additionally, aluminum profiles offer excellent corrosion resistance, durability, and cost-effectiveness, making them a reliable option for electrical grounding applications.

- Q:What are the different extrusion processes used for aluminum profiles?

- There are several different extrusion processes used for aluminum profiles, each with its own unique advantages and applications. Some of the most common extrusion processes used for aluminum profiles include: 1. Direct extrusion: This is the most common and widely used extrusion process for aluminum profiles. In direct extrusion, a heated aluminum billet is forced through a die to create the desired shape. This process is efficient, cost-effective, and suitable for producing simple to complex profiles with consistent cross-sections. 2. Indirect extrusion: In this process, the billet is held stationary while the die moves, pushing the aluminum through the die to form the profile. Indirect extrusion is often preferred for producing profiles with intricate internal features or when higher surface finish and tighter tolerances are required. 3. Impact extrusion: Impact extrusion is a specialized process used to create hollow aluminum profiles, such as tubes or containers. In this process, a slug of aluminum is placed in a die and a punch is driven into the slug, causing it to flow around the punch and form the desired shape. Impact extrusion is particularly suitable for producing thin-walled profiles with complex shapes. 4. Hydrostatic extrusion: Hydrostatic extrusion is a cold extrusion process that involves forcing the aluminum billet through a die using a high-pressure liquid. This process is often used for producing high-strength aluminum profiles with improved mechanical properties and dimensional accuracy. 5. Hot extrusion: In hot extrusion, the aluminum billet is heated to a temperature above its recrystallization point and then forced through a die. This process is typically used for producing profiles with complex shapes, as the high temperature allows for better material flow and deformation. Each extrusion process offers its own benefits and is chosen depending on the specific requirements of the aluminum profile being produced. Factors such as the desired shape, complexity, surface finish, tolerances, and mechanical properties play a significant role in determining the most suitable extrusion process for aluminum profiles.

- Q:How much is aluminum section ton?

- Aluminum prices are generally aluminum ingot + processing feesAluminum ingot to see whether you use LME or the South China Sea well-informed, or with the Yangtze River aluminum ingot prices?. Aluminum ingots generally float between 16000/ tons.Processing costs, the blank is generally 2500-3000/ tons, ordinary oxidation plus 1000 can be. If sprayed, add 500 on the basis of oxidation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile of Casting Material for Windows

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords