Aluminium Profile Glass Wall Usage and Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium Profile Glass Wall Usage and Best Quality Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile Glass Wall Usage and Best Quality:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

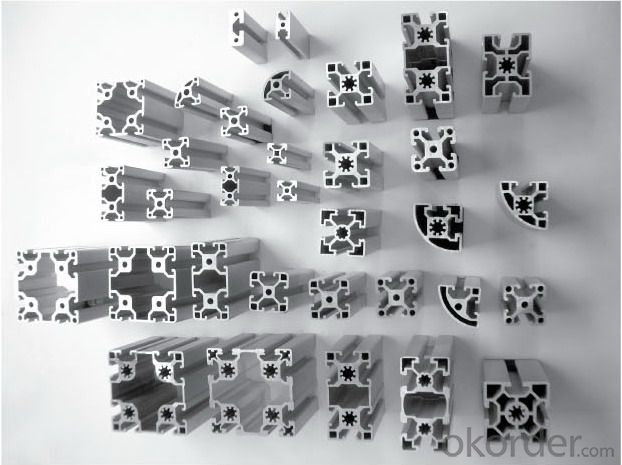

Images of the Aluminium Profile Glass Wall Usage and Best Quality:

Aluminium Profile Glass Wall Usage and Best Quality Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q:Are aluminum coils suitable for air conditioning systems?

- Yes, aluminum coils are suitable for air conditioning systems. Aluminum coils are commonly used in air conditioning systems due to their many advantages. Firstly, aluminum is a lightweight material, making it easier to handle and transport during installation. This also reduces the overall weight of the unit, making it more energy-efficient. Furthermore, aluminum coils have excellent heat transfer properties, allowing for efficient cooling of the air. They provide enhanced thermal conductivity, which helps in transferring heat quickly and effectively. This results in better cooling performance and improved energy efficiency, reducing electricity consumption and saving costs in the long run. Aluminum coils also offer superior corrosion resistance compared to other materials like copper. This is important in air conditioning systems, as they are exposed to moisture and humidity. Aluminum coils can withstand these conditions without corroding or deteriorating, ensuring longer lifespan and reliable performance. Another advantage of aluminum coils is their affordability. Aluminum is a cost-effective material, making it a popular choice for air conditioning manufacturers. This affordability can translate to lower costs for consumers, making air conditioning systems more accessible and affordable. In conclusion, aluminum coils are suitable for air conditioning systems due to their lightweight, excellent heat transfer properties, corrosion resistance, and affordability. They provide efficient cooling, durability, and cost-effectiveness, making them a preferred choice for air conditioning units.

- Q:Can aluminum coils be used in the production of aluminum windows?

- Yes, aluminum coils can be used in the production of aluminum windows. Coils are often used to create the frames and profiles of aluminum windows, as they can be easily shaped and formed into the desired configurations. This makes aluminum a popular material choice for window manufacturers due to its lightweight, durability, and corrosion-resistant properties.

- Q:What are the common surface cleaning methods for aluminum coils?

- There are several common surface cleaning methods for aluminum coils that are effective in removing dirt, debris, and other contaminants. One of the most commonly used methods is pressure washing. This involves using a high-pressure water spray to dislodge and remove any dirt or grime from the surface of the coils. Pressure washing can be done using specialized equipment or even a regular garden hose with a spray nozzle attachment. Chemical cleaning is another popular method for cleaning aluminum coils. This method involves using specific cleaning agents or solvents that are designed to break down and remove dirt and contaminants from the surface of the coils. These chemicals are typically applied using a spray bottle or a pump sprayer, and then rinsed off with water after a designated amount of time. Another effective method for cleaning aluminum coils is the use of steam cleaning. This involves using high-temperature steam to loosen and remove dirt and grime from the surface of the coils. Steam cleaning is often used in conjunction with a cleaning agent or solvent to enhance its effectiveness. In addition to these methods, there are also specialized coil cleaning brushes or fin combs that can be used to physically remove any debris or build-up from the coil surfaces. These tools are particularly useful for removing smaller particles or debris that may be trapped in between the fins of the coils. It is important to note that when cleaning aluminum coils, it is crucial to follow the manufacturer's recommendations and guidelines to ensure that the cleaning process is done safely and effectively. Additionally, regular cleaning and maintenance of aluminum coils can help prolong their lifespan and maintain their efficiency.

- Q:Can aluminum coils be used in wastewater treatment plants?

- Yes, aluminum coils can be used in wastewater treatment plants. Aluminum coils are commonly used in the construction of heat exchangers, which are essential components in wastewater treatment plants. Heat exchangers are used to transfer heat from the wastewater to the treatment process, helping to optimize the treatment efficiency and reduce energy consumption. Aluminum coils are preferred in some cases due to their excellent thermal conductivity, lightweight, and resistance to corrosion, making them suitable for the harsh environment of wastewater treatment plants. Additionally, aluminum coils are cost-effective and have a long lifespan, making them a reliable choice for use in wastewater treatment facilities.

- Q:What are the potential applications of coil-embossed aluminum coils?

- Some potential applications of coil-embossed aluminum coils include building and construction materials, such as roofing and siding, as well as decorative elements for interior design. Additionally, these coils can be used in the manufacturing of appliances, automotive parts, and packaging materials, due to their durability, aesthetics, and corrosion resistance.

- Q:what is aluminium toxic amount on a human's general physiological system? and what is the usual amount aluminium injested?thankyou

- It is estimated that the normal person takes in between 3 and 10 milligrams of aluminum per day. Aluminum is the most abundant metallic element produced by the earth. It can be absorbed into the body through the digestive tract, the lungs and the skin, and is also absorbed by and accumulates in the bodies tissues. Aluminum is found naturally in our air, water and soil. It is also used in the process of making cooking pots and pans, utensils and foil. Other items such as over the counter pain killers, anti-inflammatory products, and douche preparations can also contain aluminum. Aluminum is also an additive in most baking powders, is used in food processing, and is present in antiperspirants, toothpaste, dental amalgams, bleached flour, grated cheese, table salt, and beer, (especially when the beer is in aluminum cans). The biggest source of aluminum, however, comes from our municipal water supplies. Aluminum is excreted by the kidneys, therefore toxic amounts can impair kidney function. Aluminum can also accumulate in the brain causing seizures and reduced mental alertness. The brain is normally protected by a blood-brain barrier, which filters the blood before it reaches it. Elemental aluminum does not pass easily through this barrier, but certain compounds contained within aluminum, such as aluminum fluoride do. Interestingly, many municipal water supplies are treated with both aluminum sulfate and aluminum fluoride. These two chemicals can also combine easily in the blood. Aluminum fluoride is also poorly excreted in the urine.

- Q:I am trying to electropolish the surface of a 3003 aluminum sample to analyze in the SEM. I was wondering if anyone knew what electrolyte and electropolishing paramaters work for this alloy. So far I have used phosporic+ethanol+water at 50V for 2 minutes with minimal success.

- Aluminium needs deoxidizing also called as desmutting after electropolishing. This is done in a hot chromic acid bath for nearly for 5 minutes.

- Q:What are the common installation methods for aluminum coils?

- The common installation methods for aluminum coils include direct attachment, concealed fastening, and interlocking panel systems.

- Q:What are the different packaging weights available for aluminum coils?

- The different packaging weights available for aluminum coils vary depending on the specific requirements and applications. Common packaging weights for aluminum coils range from 1,000 to 10,000 pounds or more. These weights can be customized to meet the needs of different industries and transportation methods.

- Q:What are the common joining techniques used for aluminum coils?

- The common joining techniques used for aluminum coils include welding, soldering, and adhesive bonding.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile Glass Wall Usage and Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords