Aluminium Profile for Led Strips Lighting Project From

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

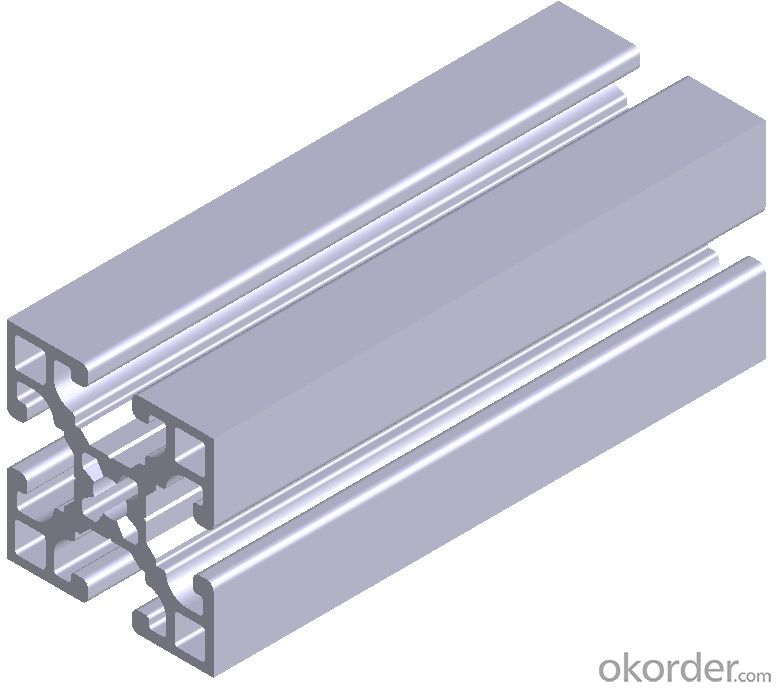

Structure of Aluminium Profile for Led Strips Lighting Project From Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile for Led Strips Lighting Project From:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

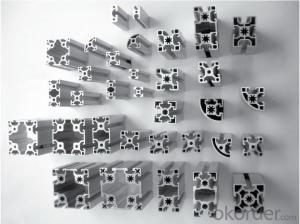

Images of the Aluminium Profile for Led Strips Lighting Project From:

Aluminium Profile for Led Strips Lighting Project From Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q:Can aluminum profiles be used for lighting fixtures or systems?

- Yes, aluminum profiles can be used for lighting fixtures or systems. Aluminum is a lightweight and durable material that is commonly used in the construction of lighting fixtures due to its excellent thermal conductivity and corrosion resistance. Aluminum profiles can be easily shaped and customized to meet the specific design requirements of lighting systems, making them a popular choice in the industry.

- Q:How do aluminum profiles contribute to water management strategies?

- Aluminum profiles play a crucial role in water management strategies due to their inherent properties and versatility. These profiles are commonly used in the construction of various water management infrastructure such as pipes, channels, and tanks, among others. Firstly, aluminum profiles are lightweight yet sturdy, making them ideal for constructing water pipes. Their lightweight nature allows for easy transportation and installation, while their strength ensures durability and resistance to corrosion. This is particularly important in water management systems as it reduces the risk of leaks and damages, ensuring the efficient and effective transport of water resources. Secondly, aluminum profiles are highly resistant to corrosion. Corrosion is a major concern in water management as it can contaminate water, reduce its quality, and damage infrastructure. By utilizing aluminum profiles, the risk of corrosion is significantly reduced, leading to improved water quality and longevity of the infrastructure. Additionally, aluminum profiles are highly customizable and can be fabricated into various shapes and sizes, allowing for the creation of efficient water management systems. These profiles can be used to construct channels, culverts, and tanks, which are crucial components of water management infrastructure. The versatility of aluminum profiles enables engineers and designers to create efficient and effective systems that can handle large volumes of water, ensuring proper water management in various scenarios such as irrigation, flood control, and wastewater treatment. Moreover, aluminum is a sustainable material that can be recycled indefinitely without losing its properties. This makes aluminum profiles an environmentally friendly choice, aligning with sustainable water management practices. By using aluminum profiles, water management strategies can minimize their environmental impact and contribute to a more sustainable future. In summary, aluminum profiles have a significant impact on water management strategies. Their lightweight yet sturdy nature, corrosion resistance, versatility, and sustainability make them indispensable in the construction of water management infrastructure. By utilizing these profiles, water management systems can be built to efficiently and effectively handle water resources, reducing the risk of contamination, improving water quality, and promoting sustainability.

- Q:How are the tonnage grades of aluminum extrusion machines classified?

- Aluminum material is soft, so it is easy to produce the top injury, pressure injury, scratch and deformation in the stamping production. Besides the requirements on the die, the following points should be done in the stamping process:1, to make aluminum stamping, reducing non-performing rate, the first to do 5S, especially clean, including mold, punch table, pipeline and packaging materials must be no sharp debris, no dirt regularly clear rectification, the upper and lower mold must be clean without debris.2, found that product burr larger, must promptly send mold maintenance, and follow the results.3, aluminum parts easier to heat, and the backlog of hard together, so in the blanking, when the material needs to be coated with a little pressure on the oil (to heat dissipation, but also smooth to clear the material), and then stamping.4, punching more products need to do blow cleaning the mold surface, do product mould, keep clean, reduce top injury, injury must be found on top of the mold top point to find out and solve the injury problems to continue production.5, push the flat mold block will produce aluminum chip, so push block production every day, must be washed under the push block aluminum scrap.Our company with advanced production equipment and technology, relying on a strong technical team, and has established a perfect quality management system, ensure the reliable quality of products, products with first-class quality, reasonable price, sold in the city and region, sales performance is good, whether we are in a peer or in the guest account, have a high reputation.

- Q:What are the design options for aluminum profiles?

- When it comes to aluminum profiles, there are numerous design options available, offering a wide range of applications and customization possibilities. Here are some commonly used design options for aluminum profiles: 1. Various Extrusion Shapes: Aluminum profiles can be extruded into different shapes, including square, rectangular, round, T-shaped, I-shaped, or custom profiles. This shape flexibility enables designers to create profiles that perfectly match their project requirements. 2. Diverse Surface Finishes: Aluminum profiles can be finished with various surface treatments to enhance their appearance and protect them from corrosion. Popular surface finishes include anodizing, powder coating, polishing, brushing, and laminating. These finishes offer a variety of colors, textures, and levels of glossiness to suit specific design preferences. 3. T-Slot Profiles: T-slot profiles are a type of aluminum extrusion with a T-shaped slot on one or more sides. These profiles are commonly used in constructing frameworks, machine guards, and other structures that require easy assembly and reconfiguration. The T-slot design facilitates convenient insertion and adjustment of connecting elements, such as bolts, nuts, and brackets. 4. Thermal Break Profiles: Thermal break profiles are designed with a thermal barrier inserted between the interior and exterior parts of the profile. This design minimizes the transfer of heat or cold between the two sides, making them suitable for applications where thermal insulation is crucial, such as windows, doors, and curtain walls. 5. Customization Options: Aluminum profiles can be further customized through additional machining processes, such as cutting, drilling, tapping, milling, or bending. These processes allow for the creation of unique shapes, hole patterns, or features that meet specific design requirements. 6. Integration Capability: Aluminum profiles can be designed to integrate with other components or systems, such as hinges, connectors, fasteners, or brackets. This integration capability provides flexibility in assembly and enables the creation of complex structures or modular systems. In summary, the design options for aluminum profiles are extensive, offering versatility, functionality, and aesthetic appeal. Designers have the freedom to choose from a wide range of shapes, finishes, and additional features to create aluminum profiles that precisely meet their project needs.

- Q:Can aluminum profiles be painted or coated?

- Aluminum profiles possess the ability to undergo painting or coating processes. The versatility of aluminum as a material allows for easy application of paint or coating, thereby enhancing its appearance, providing corrosion resistance, and improving durability. Numerous techniques exist for painting or coating aluminum profiles, such as powder coating, anodizing, and liquid coating. Powder coating stands as a favored option due to its capacity to deliver a lasting and consistent finish, while anodizing forms a protective oxide layer on the aluminum's surface. Conversely, liquid coating offers a broad spectrum of colors and finishes. In summary, painting or coating represents an effective and practical choice for individuals seeking to alter color, enhance aesthetics, or safeguard aluminum profiles.

- Q:How do I install aluminum profiles?

- Follow these steps to install aluminum profiles: 1. Begin by selecting the desired location for the aluminum profile installation and ensure the surface is clean and debris-free. 2. Precisely and smoothly cut the aluminum profile to the required length using a saw or miter saw. 3. Create pilot holes at regular intervals along the marked installation area using a drill. These holes will serve as anchor points for the screws or bolts that will secure the aluminum profile. 4. Align the pilot holes on the aluminum profile with the corresponding holes on the surface. Insert screws or bolts through the holes and tighten them using a screwdriver or socket wrench. 5. If you are installing multiple aluminum profiles, repeat the process for each section, ensuring they are aligned and securely fastened. 6. Once all profiles are installed, inspect for any gaps or unevenness. Adjust and tighten the screws or bolts as necessary to ensure a snug fit. 7. Lastly, clean the installed aluminum profiles using a mild cleaning solution and soft cloth to remove any dirt or residue. Remember to wear appropriate safety gear, such as gloves and safety glasses, when handling tools and materials during the installation process.

- Q:Can aluminum profiles be used in construction?

- Yes, aluminum profiles can be used in construction. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various construction applications. It is often used in the construction of windows, doors, curtain walls, and roofing systems. Aluminum profiles offer flexibility in design, allowing for the creation of complex shapes and structures. Additionally, aluminum is a sustainable material as it is highly recyclable, making it an environmentally friendly choice for construction projects.

- Q:What are the reasons for the slow down of aluminum extrusion press?

- Check the overflow valve alone pressure is not fast enough, if not fast enough, there may be a damper plug, remove, try again

- Q:Are aluminum profiles suitable for electrical applications?

- Yes, aluminum profiles are suitable for electrical applications. Aluminum is a versatile and lightweight metal that offers excellent electrical conductivity, making it a popular choice for various electrical components and systems. Aluminum profiles can be used for electrical enclosures, heat sinks, bus bars, and other electrical connectors. One of the key advantages of aluminum profiles in electrical applications is their high thermal conductivity. Aluminum efficiently dissipates heat, thereby helping to keep electrical components cool and preventing overheating. This is especially important in applications where heat generation is a concern, such as in power electronics or LED lighting. Moreover, aluminum profiles offer good corrosion resistance, which is crucial in electrical applications where exposure to moisture or harsh environments is common. Aluminum naturally forms a protective oxide layer on its surface, which acts as a barrier against corrosion, ensuring the longevity and reliability of electrical systems. Another benefit of aluminum profiles is their ease of fabrication. Aluminum can be easily machined, welded, and extruded into various shapes and sizes, allowing for customized designs and easy installation. This flexibility makes aluminum profiles suitable for a wide range of electrical applications, from small consumer electronics to large-scale industrial systems. Additionally, aluminum is a cost-effective material compared to other metals like copper or steel, offering significant savings in manufacturing and maintenance costs. It is also a highly recyclable material, making it an environmentally friendly choice for electrical applications. In conclusion, aluminum profiles are indeed suitable for electrical applications due to their excellent electrical conductivity, thermal efficiency, corrosion resistance, ease of fabrication, cost-effectiveness, and sustainability.

- Q:Is the aluminum profile insulated and broken hot?

- Yes, the name is not the same, the professional name is "broken hot aluminum alloy", most people used to call "broken bridge aluminum"

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile for Led Strips Lighting Project From

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords