Aluminium Profile for Curtain Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

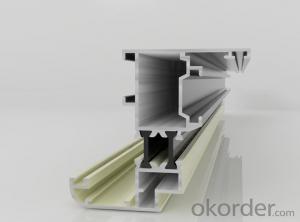

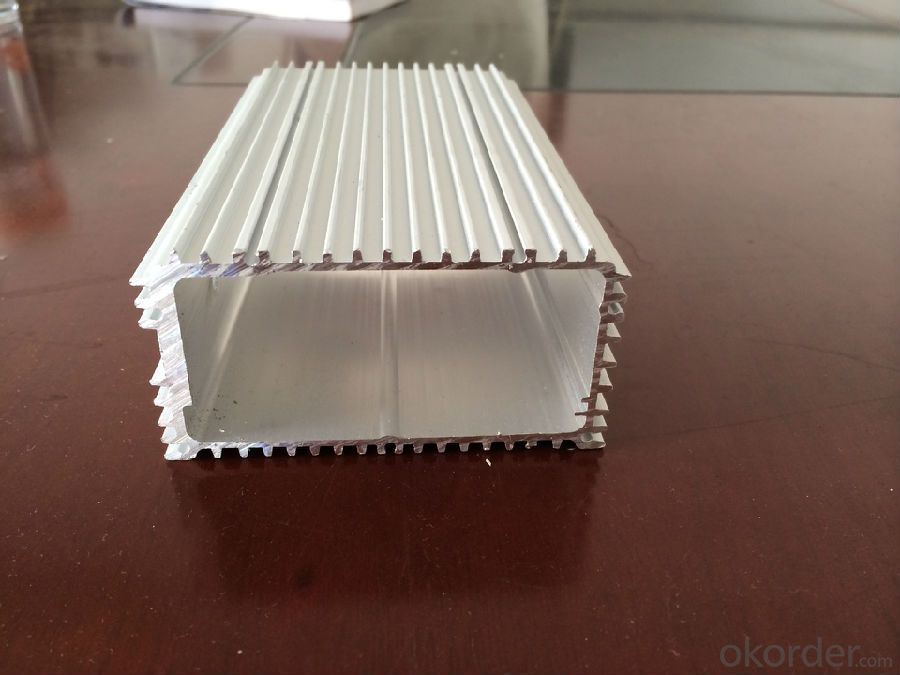

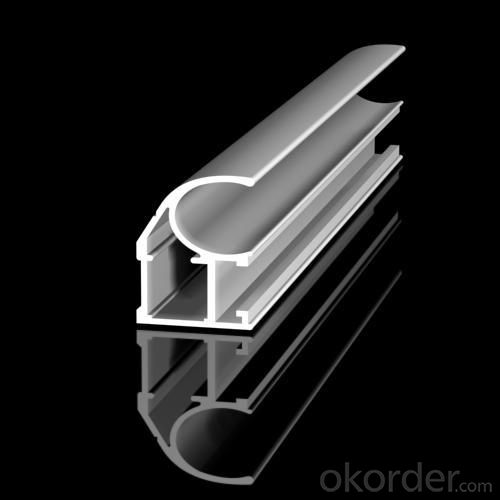

Structure of Aluminium Profile for Curtain Wall Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile for Curtain Wall Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Profile for Curtain Wall Application:

Aluminium Profile for Curtain Wall Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:How are aluminum coils used in the manufacturing of household appliances?

- Aluminum coils are used in the manufacturing of household appliances as they provide excellent conductivity, durability, and corrosion resistance. These coils are commonly used in appliances such as refrigerators, air conditioners, and heating systems. They help in transferring heat efficiently, improving energy efficiency, and ensuring the longevity of the appliance. Additionally, aluminum coils are lightweight, making them easier to handle during the manufacturing process.

- Q:Why does aluminum foil burn in the microwave but not in the oven?

- Because of the conductive nature of foil intensifies the microwaves in small areas of the foil to a temperature far greater than can be achieved in an oven.

- Q:What maintenance is required for aluminum coils?

- Maintenance for aluminum coils typically includes regular cleaning and inspection to ensure efficient performance and longevity. Here are some specific maintenance requirements for aluminum coils: 1. Cleaning: Regularly clean the aluminum coils to remove dirt, dust, and debris that can accumulate on the surface. Use a soft brush or a vacuum cleaner with a brush attachment to gently remove any loose particles. Avoid using abrasive cleaners or brushes that can scratch or damage the surface of the aluminum. 2. Inspection: Periodically inspect the aluminum coils for signs of damage or wear. Check for any bent or dented fins, which can restrict airflow and reduce the coils' efficiency. Look for signs of corrosion, such as discoloration or pitting, as this can affect the coils' performance and lifespan. 3. Coil Protection: Apply a protective coating or sealant to the aluminum coils to prevent corrosion and damage from exposure to moisture, chemicals, or harsh environmental conditions. This can help prolong the life of the coils and maintain their performance. 4. Lubrication: If your aluminum coils are part of a mechanical system, such as an HVAC unit, ensure that any moving parts are properly lubricated. This can help reduce friction and wear on the coils, improving their efficiency and preventing premature failure. 5. Professional Maintenance: Consider scheduling regular professional maintenance for your aluminum coils, especially if they are part of a larger system. HVAC technicians or specialized coil cleaning services can provide a thorough inspection, cleaning, and maintenance to ensure optimal performance and identify any potential issues early on. By following these maintenance practices, you can help extend the lifespan of your aluminum coils, improve their efficiency, and prevent costly repairs or replacements.

- Q:Are aluminum coils susceptible to warping or bending?

- Yes, aluminum coils are susceptible to warping or bending due to their relatively low strength and flexibility.

- Q:What happened to the aluminum coil coming out of the annealing furnace?

- There is oil on the aluminum coil and the annealing time is too long.

- Q:aluminium plate - 1800mm x 950mm x 1.5mmprocesses - i) sandblasting ii) polyethylene coating iii) matt blastingWhy does aluminium plate warp after the first process?How to prevent warping? Other than increasing material thickness (weight issue)

- Cold rolled aluminium may get stress relieved by sand-blasting and thus get warped. Normally warping should not take place if sand blasting is done on both sides. Another potential reason could be lack of adequate support for the plate during blasting. Check out these factors and take corrective action.

- Q:Can aluminum coils be used in extreme weather conditions?

- Aluminum coils are capable of being utilized in the harshest weather conditions. With its exceptional durability and resistance to corrosion, aluminum proves to be a formidable material that can endure extreme heat, cold, humidity, as well as heavy rain or snow. Notably, it finds extensive employment in essential areas where weather resistance holds paramount importance, including air conditioning systems, refrigeration units, and outdoor equipment. These coils are expressly engineered to possess remarkable strength and dependability, ensuring their suitability for deployment in severe weather conditions, all the while maintaining optimal performance and lasting durability.

- Q:Are aluminum coils suitable for architectural roofing systems?

- Yes, aluminum coils are suitable for architectural roofing systems. Aluminum is lightweight, durable, and corrosion-resistant, making it an excellent choice for roofs. It can withstand harsh weather conditions, is easy to work with, and offers a range of design possibilities. Additionally, aluminum coils are available in a variety of colors and finishes, allowing for customization and enhancing the aesthetic appeal of architectural roofing systems.

- Q:What is the balanced chemical equation for aluminum and cobalt?That is all the information that the question gives. If you could help me out, I would really, really appreciate it.

- That's pretty sparse. Perhaps the question is referring to a single replacement reaction. Aluminum is above cobalt in the activity series, which allows us to predict that aluminum metal will reduce cobalt ions, while aluminum is oxidized. This occurs as long as there is an ion present which will react with the aluminum oxide layer on the surface of aluminum. This passivating Al2O3 layer keeps aluminum metal from reacting. The presence of chloride ions will break down the passivating layer allowing the aluminum metal below to react. Al2O3(s) + 6H+ + 8Cl- -- 2[AlCl4]- + 3H2O(l) 2Al(s) + 3Co2+ -- 2Al3+ + 3Co(s)

- Q:What industries utilize aluminum coils?

- Several industries utilize aluminum coils across various applications. Some of the main industries include the automotive sector, where aluminum coils are used in the manufacturing of vehicle bodies and parts to reduce weight and improve fuel efficiency. The construction industry also extensively uses aluminum coils for roofing, cladding, and insulation purposes due to their durability and corrosion resistance. Additionally, the aerospace industry relies on aluminum coils for aircraft construction, as they offer a lightweight yet sturdy material for structural components. Other industries such as packaging, electronics, and HVAC (heating, ventilation, and air conditioning) also make use of aluminum coils for their specific requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile for Curtain Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords