Aluminium Profile Anodizing with Different Color

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminium Profile Anodizing with Different Color Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile Anodizing with Different Color:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

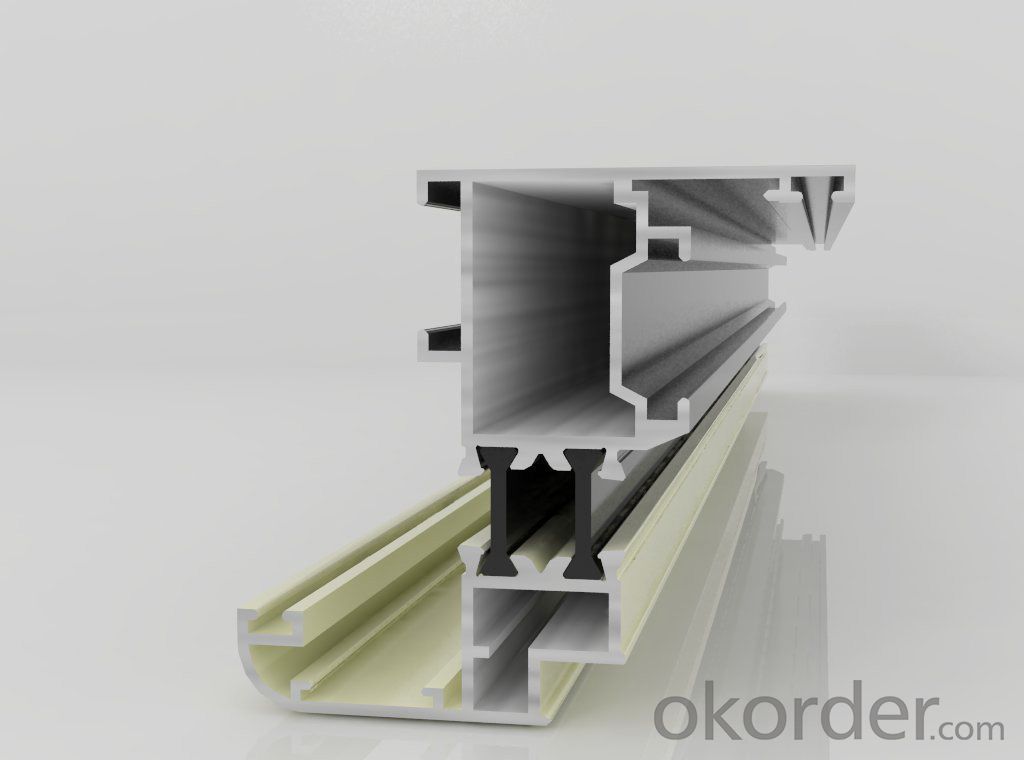

3.Aluminium Profile Anodizing with Different Color Images:

4.Aluminium Profile Anodizing with Different Color Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What are the aluminum profile markets in Cangzhou, Renqiu?

- Aluminum market, located in Renqiu city in Yi Zhen Zhang Liu Zhuang industrial area, if you find a direct about Liu Zhuang industrial zone can be. Known as the North's largest aluminum production base, I look not so good

- Q:Can aluminum profiles be used in cleanroom environments?

- Yes, aluminum profiles can be used in cleanroom environments. Aluminum is a lightweight and versatile material that possesses many desirable qualities for cleanroom applications. It is non-corrosive, non-magnetic, and has a high strength-to-weight ratio, making it suitable for constructing cleanroom structures such as walls, partitions, and equipment racks. Aluminum profiles can be easily assembled and disassembled, allowing for flexible cleanroom configurations and future modifications. They can also be integrated with other materials like glass, acrylic, or stainless steel to meet specific cleanroom requirements. Additionally, aluminum profiles can be anodized or coated to enhance their cleanliness and resistance to contamination. Anodization provides a protective layer on the surface of the aluminum, making it more resistant to scratches and wear. Coatings such as epoxy or powder coatings can further improve the durability and cleanliness of the profiles. Overall, aluminum profiles offer numerous advantages for cleanroom applications, including their lightweight nature, strength, corrosion resistance, and flexibility in design.

- Q:Can aluminum profiles be used in load-bearing structures?

- Aluminum profiles are indeed applicable in load-bearing structures. With its lightweight and remarkable durability, aluminum possesses an exceptional strength-to-weight ratio that renders it suitable for diverse load-bearing applications. The profiles can be customized and produced to endure significant loads, making them an ideal choice for bridges, buildings, and industrial frameworks. Additionally, aluminum profiles exhibit corrosion-resistant properties, further enhancing their suitability for load-bearing structures in different environments. Nevertheless, it is crucial to carefully consider the specific design needs, load circumstances, and accurate engineering calculations to guarantee that the aluminum profiles are appropriately sized and reinforced for their intended load-bearing purposes.

- Q:What are the different surface brushing options for aluminum profiles?

- Aluminum profiles offer a range of surface brushing options, each with its own distinctive appearance and practical features. 1. Mechanical Brushing: By utilizing abrasive brushes or pads, a consistent brushed pattern is created on the surface of the aluminum profile. This linear finish enhances the material's visual appeal and effectively conceals minor imperfections and scratches, making it a favored option for decorative purposes. 2. Chemical Brushing: Also referred to as chemical etching, this technique involves the application of a chemical solution to the aluminum profile's surface. The solution selectively removes a thin layer of metal, resulting in a brushed effect. Manufacturers can control the intensity of brushing to achieve different levels, enabling them to create matte or satin finishes. 3. Sandblasting: This surface treatment method entails propelling fine particles onto the aluminum profile's surface at high speeds. The abrasive particles remove the outer layer of metal, producing a textured brushed finish. Sandblasting can be adjusted to achieve varying degrees of roughness and depth, making it suitable for diverse applications. 4. Wire Brushing: Wire brushing is a manual technique that employs a wire brush to create a brushed pattern on the aluminum profile's surface. It allows for precise control over the direction and intensity of brushing, making it a suitable choice for customized designs. Depending on the pressure applied and the type of brush used, wire brushing can achieve both light and heavy brushed finishes. 5. Anodizing: Anodizing is an electrochemical process that involves forming an oxide layer on the surface of the aluminum profile. This process not only enhances the material's corrosion resistance but also allows for the application of various decorative finishes, including brushed patterns. Prior to anodizing, aluminum profiles can undergo mechanical brushing or chemical etching to achieve the desired brushed effect. In conclusion, the selection of a surface brushing option for aluminum profiles depends on the desired finish, functionality, and specific application requirements. Manufacturers consider factors such as aesthetic appeal, durability, corrosion resistance, and ease of maintenance when choosing the appropriate technique.

- Q:What are the differences between standard and non - standard shapes?

- Hello, not within the scope of the national standard, so it is called non-standard,The standard piece is within the national standardThat's the difference,This GB standard can be found, are unified

- Q:What are the different methods of joining aluminum profiles together?

- There are various ways to connect aluminum profiles, depending on the desired result and specific application. The most commonly used techniques include: 1. Mechanical fastening: To secure aluminum profiles, screws, bolts, or rivets can be employed. This method is straightforward and cost-effective, suitable for different applications. However, it may leave visible fasteners and require additional finishing. 2. Welding: Aluminum profiles can be joined using different welding techniques like TIG, MIG, or laser welding. Welding creates a sturdy and seamless joint, making it ideal for structural purposes. However, it demands specialized equipment and expertise. 3. Adhesive bonding: Specialized adhesives for aluminum bonding can be utilized to connect profiles. This technique offers high strength, even stress distribution, and a clean appearance. Adhesive bonding is commonly used for lightweight applications or when welding is not feasible. 4. Slotting and interlocking: Profiles with specially designed slots or interlocking features can be connected without additional hardware. This method ensures a seamless and neat appearance while maintaining structural integrity. 5. Thermal joining: Heat-based methods like hot plate welding or induction heating can be employed to connect aluminum profiles. These processes involve melting a portion of the aluminum surface and bonding it upon cooling. Thermal joining provides both strength and aesthetics without requiring extra materials. 6. Extrusion-based connectors: Connectors designed for extrusion are components that allow for the joining of aluminum profiles. These connectors are typically inserted into the slots or channels of the profiles, providing a secure and long-lasting connection. When choosing the appropriate method for joining aluminum profiles, it is necessary to consider factors such as strength requirements, appearance, ease of assembly, and cost. Each method has its own advantages and limitations, so the most suitable technique depends on the specific application and desired outcome.

- Q:How can I control the hardness of 6063 aluminum profile at 6-9 degrees?

- Two 、 soft burning treatment:2.1 purpose:Materials for stretching and stretching include rolling materials, extrusion materials and forging materials:Casting - Hot Processing - cold processing - finished materialIn the process of hot or cold processing processing, material processing hardening, the strength increases or lead to work hardening, the strength increases or lead to reduced processing. In order to eliminate the work hardening, for cold working before or after the application of heat treatment is soft burning treatment. Its purpose is to make use of the material is needed.2.2 classification:Due to the different conditions of soft burning:2.2.1 part of soft burning: only part of the work hardening is eliminated, the treatment temperature is below the recrystallization temperature, the actual temperature depends on the strength, and the higher the strength, the lower the treatment temperature2.2.2 completely soft burning: treatment temperature in the recrystallization temperature or slightly higher, so that the material recrystallization, and completely eliminate the work hardening, also make the strength to the lowest stateThere is time and soft burning:2.2.3 soft burning before cold or cold start process, soft burning treatment added, usually completely soft burning, its purpose in the recovery process, and make the next function more smoothly, and the control of the organization, in order to fit for the final product requirements.2.2.4 ultimate soft burning: the main purpose is to adjust the final strength level of the finished product, that is, to adjust the chain3 processing common sense

- Q:How do you prevent warping or distortion of aluminum profiles during fabrication?

- To prevent warping or distortion of aluminum profiles during fabrication, there are several key steps that can be taken: 1. Proper storage: Before fabrication, it is crucial to store aluminum profiles in a controlled environment with stable temperature and humidity levels. This helps to minimize any potential changes in the metal's shape or dimensions. 2. Correct handling: Aluminum profiles should be handled with care to avoid bending or twisting. This includes using appropriate lifting equipment, avoiding excessive force, and ensuring that the profiles are supported evenly during transportation. 3. Proper machining techniques: During fabrication, it is important to use appropriate machining techniques that minimize heat buildup. Excessive heat can cause the aluminum to expand and potentially warp. Cooling techniques like using lubricants or coolants can help dissipate heat and prevent distortion. 4. Controlled welding: When welding aluminum profiles, it is crucial to maintain proper control over the welding process. The use of appropriate welding techniques, such as preheating and post-weld heat treatment, can help minimize distortion. 5. Adequate fixturing: Using proper fixturing methods during fabrication helps ensure that the aluminum profiles are held in the correct position throughout the process. This prevents any unintended bending or warping that could occur due to improper support or clamping. 6. Stress-relieving: After fabrication, stress-relieving processes can be employed to minimize residual stresses within the aluminum profiles. This helps to prevent distortion or warping that may occur during subsequent handling or usage. 7. Quality control: Regular inspection and measurement of the aluminum profiles during fabrication can help identify any deviations from the desired specifications. This enables quick corrective actions to be taken, minimizing the risk of warping or distortion. By following these steps, manufacturers can significantly reduce the likelihood of warping or distortion in aluminum profiles during fabrication, ensuring the production of high-quality components or products.

- Q:Are aluminum profiles suitable for interior design applications?

- Yes, aluminum profiles are suitable for interior design applications. They are versatile, lightweight, and can be easily customized to fit various designs and purposes. Aluminum profiles offer a modern and sleek aesthetic, and they are commonly used for items such as doors, windows, partitions, furniture, and decorative elements. Additionally, aluminum is durable, corrosion-resistant, and requires minimal maintenance, making it a practical choice for interior design projects.

- Q:Chengdu where to sell aluminum profiles of many businesses?

- Bus route Liang Jia lane to Qingbaijiang on the car, told the driver to Fengxiang market under the line, and 6 yuan fare, cheaper! Drive away the State Road 108 to Mi Mou Town, Fengxiang market in 108 State Road next great, far away saw. This is the latest information, 2013-9-12

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile Anodizing with Different Color

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords