Aluminium Profile 180T Best Price and Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium Profile 180T Best Price and Good Quality Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile 180T Best Price and Good Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

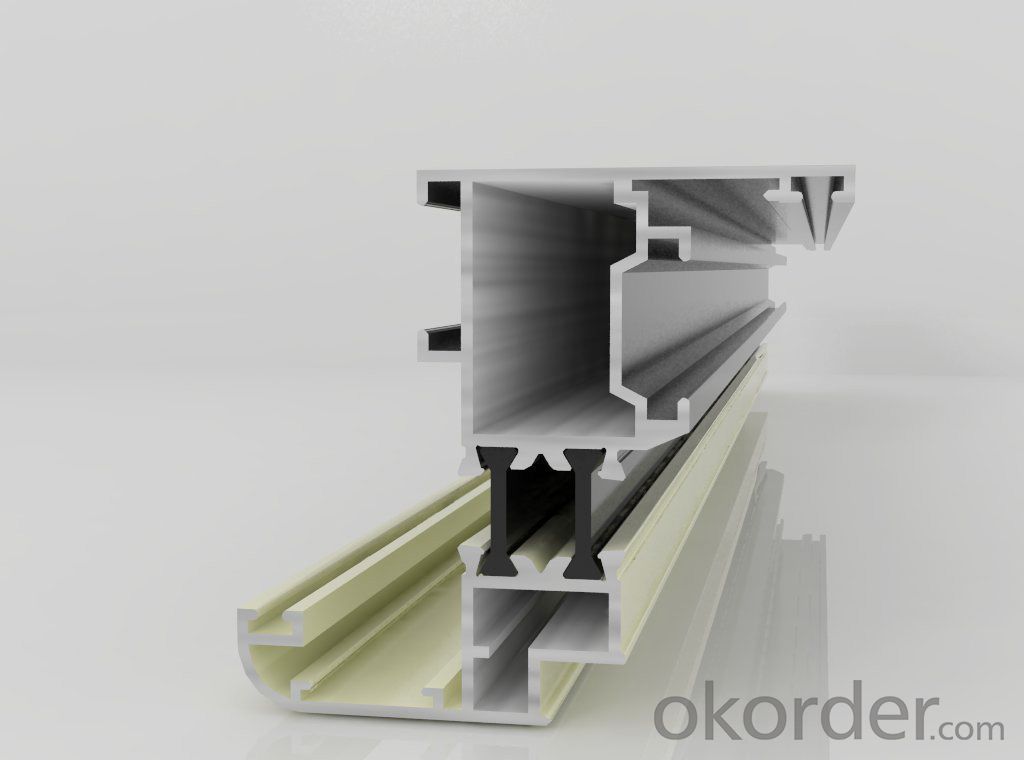

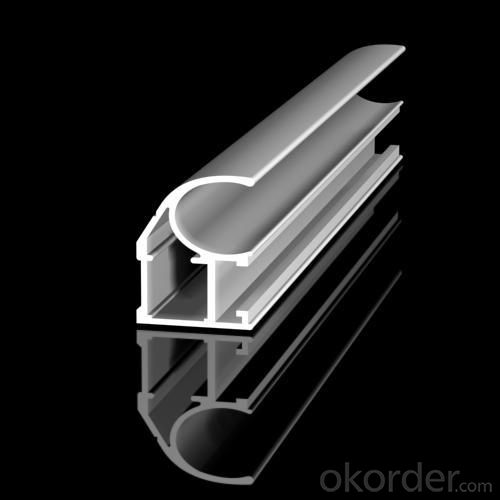

Images of the Aluminium Profile 180T Best Price and Good Quality:

Aluminium Profile 180T Best Price and Good Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:Are aluminum coils suitable for architectural facades?

- Architectural facades can benefit from the use of aluminum coils. This material is favored for its many advantages. Firstly, aluminum's lightweight nature makes it easy to handle and install, especially for complex architectural designs or tall buildings. Secondly, aluminum is highly durable and resistant to corrosion. It naturally resists rust and does not need additional treatments or coatings. This makes aluminum coils suitable for long-term use in various weather conditions, such as coastal areas or harsh climates where corrosion is a concern. Moreover, aluminum coils offer versatility in terms of design and customization. They can be easily shaped into different sizes, profiles, and forms, allowing architects and designers to create unique facades that meet their specific requirements. Aluminum can also be painted or coated in various colors and finishes to achieve the desired aesthetic appeal. In addition to its functional and aesthetic advantages, aluminum is also an environmentally friendly choice. It is a recyclable material, meaning it can be reused endlessly without losing its properties. This makes aluminum coils a sustainable option for architectural facades, aligning with the increasing emphasis on green building practices. Overall, due to their lightweight nature, durability, versatility, and sustainability, aluminum coils are a suitable choice for architectural facades. They offer a wide range of design possibilities while ensuring long-term performance and minimal maintenance requirements.

- Q:Just wondering if an aluminum and Fluoride bond can be created by boiling fluoridated water in aluminum cookware?

- Yes. okorder /

- Q:I had a physics exams today and it was asking whether or not a shiny surface aluminium blanket was suitable to keep the sleeper warm. I put that because it's a conductor of electricitiy, heat loss will be greater so it wont be suitable for keeping him warm. On the other hand, some other people said that because it had a shiny surface, thus a good reflector of heat, it would be suitable for keeping him warm. Are both arguments correct?

- Metals are reflective for the comparable reason that they habit electrical energy. The steel has an excellent number of electrons that are very loosely guaranteed to the atoms; they are in a position to leap from one atom to a distinctive very quite. that's virtually like a sea of electrons. Electrons soak up photons of sunshine then re-emit them in random instructions, that's stated as scattering. you are able to think of that if the electrons emit the photons in random instructions then the floor could be boring white, no longer vivid, yet in reality so long as a results of fact the floor irregularities on the steel are smaller than a wavelength of sunshine each and all of the photons entering into extraordinary instructions cancel one yet another out, in simple terms leaving those that leap off on the comparable attitude they arrived at - mirrored photograph in different words. Metals are literally sparkling. you are able to locate that frustrating to have self belief yet once you're finding at an liquid crystal reveal reveal screen you're finding by using a layer of steel now - it varieties electric powered circuits on the returned of the glass reveal. Any cloth that reflects easy additionally transmits it. while the electrons are greater efficient at interacting with the photons of sunshine the fabric is greater reflective, as in a steel; while fewer electrons are interacting with the easy the fabric is greater transmissive, like glass or water. yet observe that cup and water the two mirror easy besides as transmit it.

- Q:I have a electrical project to do, and could save about $300.00 by using aluminum wire since I can get it free, but I have never used aluminum before, and am not sure if it is a good way to go.

- Aluminum wire can be connected to copper wire with the proper connector

- Q:What is the cost of aluminum coils compared to other metals?

- The price of aluminum coils can change depending on various factors such as market demand, availability, and current economic conditions when compared to other metals. Generally, aluminum is considered to be more affordable in comparison to metals like copper or stainless steel. Due to its lightweight, resistance to corrosion, and excellent thermal conductivity, aluminum is extensively used in different industries. It is the preferred choice for applications in construction, automotive, aerospace, and electrical industries. When compared to copper, aluminum typically has a lower cost per pound. However, it is important to note that copper is highly regarded for its superior electrical conductivity and is often favored in specific applications where electrical performance is crucial. In contrast, stainless steel is generally pricier than aluminum. Stainless steel provides exceptional resistance to corrosion and durability, making it suitable for applications that require high strength and the ability to withstand harsh environments. In conclusion, when considering the cost of aluminum coils in relation to other metals, aluminum is frequently a more cost-effective option. Nevertheless, it is crucial to evaluate the specific requirements and performance characteristics needed for a particular application in order to determine the most suitable metal choice.

- Q:How do aluminum coils compare to steel coils in terms of strength?

- Significant differences can be observed between aluminum coils and steel coils in terms of strength. Generally speaking, steel coils exhibit greater strength and durability when compared to their aluminum counterparts. This can be attributed to steel's renowned high tensile strength and ability to withstand heavy loads, making it the favored selection for applications that prioritize strength and durability. Conversely, aluminum coils possess a lower strength in comparison to steel. Aluminum, as a lightweight metal, exhibits a lower tensile strength, implying that it may not offer the same resistance to heavy loads or stress as steel coils. Nonetheless, aluminum coils boast other advantageous properties, including exceptional corrosion resistance and high thermal conductivity. The decision to opt for either aluminum or steel coils relies on the specific application and its requirements. If strength and durability take precedence, steel coils are generally the superior choice. However, if weight reduction, corrosion resistance, or thermal conductivity are of greater importance, aluminum coils may be the preferred option.

- Q:I would like to know why the ionic substance aluminium oxide doesn't dissolve in water.

- It does dissolve, but only slightly. It has a solubility of about 0.0001 under atmospheric pressure, it doesn't dissolve because the aluminium is extremely strongly bonded to oxygen, so it can't dissociate very much at all. If you want to dissolve aluminium oxide, you should use an alkaline solution.

- Q:Can aluminum coils be used for cladding purposes?

- Yes, aluminum coils can be used for cladding purposes. Aluminum is a popular choice for cladding due to its lightweight nature, durability, corrosion resistance, and versatility. Aluminum coils can be used to create a wide range of cladding systems, including curtain walls, rain screens, and facade panels. These coils can be easily formed, cut, and installed, making them an efficient and cost-effective solution for cladding. Additionally, aluminum's natural oxide layer provides protection against weathering and requires minimal maintenance. Overall, aluminum coils are a suitable option for cladding purposes, offering both aesthetic appeal and functional benefits.

- Q:How are aluminum coils protected against transportation damage?

- The prevention of transportation damage to aluminum coils is ensured by manufacturers and transportation companies through various measures. Primary among these measures is the packaging and storage of the coils in robust crates or pallets, which act as a barrier against external impact and guarantee stability during transit. These crates, which are typically constructed from wood or metal, are specifically designed to withstand the challenges of transportation. To provide further protection against damage, the coils are often enveloped in protective materials like plastic or stretch film. This supplementary layer of packaging serves to prevent scratches, abrasions, and moisture damage that may occur during handling and transportation. In addition, the coils are frequently secured within the crates or pallets using straps or bands, thereby averting any potential movement or collision with other objects. In order to create a cushioning effect within the packaging, manufacturers frequently employ padding materials such as foam or cardboard inserts. These inserts absorb shock and vibration during transit, thereby reducing the likelihood of damage caused by impacts or sudden movements. Transportation companies also play a critical role in ensuring the secure transportation of aluminum coils. They utilize specialized handling equipment, such as forklifts or cranes, to minimize the risk of mishandling and dropping the coils. Furthermore, they meticulously load and secure the coils within shipping containers or trucks, ensuring proper bracing and immobilization to prevent shifting or rolling during transportation. In conclusion, the protection of aluminum coils from transportation damage is achieved through the utilization of robust packaging, protective wraps, padding materials, and appropriate handling techniques. These measures aim to minimize the risk of scratches, dents, and other forms of damage caused by impacts, vibrations, or mishandling during transit.

- Q:Are there any restrictions on the coil thickness of aluminum coils?

- Yes, there are typically restrictions on the coil thickness of aluminum coils. The specific restrictions may vary depending on the intended application and industry standards. Generally, the thickness of aluminum coils is limited by the capabilities of the manufacturing equipment and the desired final product. Thinner coils are often preferred for applications that require flexibility, such as in the manufacturing of foils or flexible packaging materials. On the other hand, thicker coils are commonly used in industries like construction or automotive, where strength and durability are important factors. Additionally, the thickness of aluminum coils may be restricted by the availability and cost of raw materials. It is important for manufacturers to adhere to these restrictions to ensure the quality and performance of the final product.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile 180T Best Price and Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords