Aluminium Prepainted Coil with PVDF and Different Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

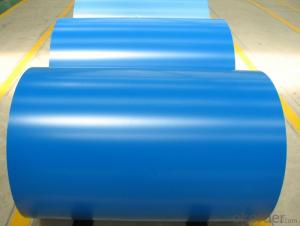

Structure of Aluminium Prepainted Coil with PVDF and Different Colors Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted Coil with PVDF and Different Colors:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Prepainted Coil with PVDF and Different Colors:

Aluminium Prepainted Coil with PVDF and Different Colors Coil Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:Can aluminum sheets be used for electrical conductors?

- Yes, aluminum sheets can be used for electrical conductors. Aluminum is a good conductor of electricity and is commonly used in various electrical applications such as wiring, cables, and power transmission lines.

- Q:Can aluminum sheets be used for air ducts?

- Indeed, air ducts can utilize aluminum sheets. Aluminum, known for its lightweight and durable characteristics, is frequently employed in air ducts. Its resistance to corrosion renders it a suitable option for HVAC systems. Air ducts are often constructed using aluminum sheets due to their malleability, enabling easy bending and shaping to meet specific dimensions. Moreover, aluminum boasts commendable thermal conductivity, ensuring efficient heat transfer within the ducts. Ultimately, opting for aluminum sheets in air ducts proves to be a pragmatic and efficient decision.

- Q:Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Indeed, aluminum sheets are well-suited for the production of electronic enclosures. The reason for aluminum's popularity in this regard lies in its remarkable combination of strength, durability, and lightness. Moreover, its capacity for conducting electricity effectively qualifies it for dissipating the heat generated by electronic components. Furthermore, aluminum sheets can be effortlessly molded, shaped, and machined to meet the precise specifications of electronic enclosures, thereby allowing for personalized and adaptable designs. Additionally, its ability to resist corrosion renders it suitable for safeguarding electronic devices against environmental elements. In summary, aluminum sheets offer the perfect material solution for the manufacturing of electronic enclosures.

- Q:Are aluminum sheets conductive?

- Indeed, aluminum sheets possess conductivity. Being a metal, aluminum exhibits exceptional electrical conductivity. Consequently, aluminum sheets facilitate the smooth passage of electricity, rendering them suitable for an array of applications that necessitate conductivity, including electrical wiring, power transmission lines, and electronic devices.

- Q:Can aluminum sheets be used for storage tanks?

- Indeed, storage tanks can make use of aluminum sheets. Due to its lightweight nature and resistance to corrosion, aluminum proves to be a fitting option for the containment of diverse substances, including water, chemicals, and fuel. Its remarkable durability allows it to endure even the harshest environmental conditions. Moreover, constructing and maintaining aluminum tanks is comparatively straightforward. Nonetheless, it is crucial to take into account the specific necessities of the substance being stored and seek guidance from professionals or engineers to ascertain that aluminum sheets are the suitable selection for the given storage tank.

- Q:Are the aluminum sheets suitable for manufacturing aircraft interiors?

- Aluminum sheets are an excellent choice for producing aircraft interiors. Not only is aluminum lightweight, but it is also strong and durable, making it perfect for aerospace applications. Its high strength-to-weight ratio allows for the creation of fuel-efficient and lightweight aircraft. Moreover, aluminum sheets are highly resistant to corrosion, which is vital in the aerospace industry. Aircraft interiors are exposed to various environmental factors like humidity and temperature changes. The corrosion resistance of aluminum ensures that the aircraft interior components remain reliable and long-lasting, thereby reducing maintenance and replacement expenses. Additionally, aluminum sheets can be easily fabricated and shaped into different forms. This feature enables the production of intricate and customized aircraft interior components. Aluminum sheets can be effortlessly cut, bent, and welded, offering design flexibility and allowing manufacturers to create visually appealing interior designs. Apart from these technical advantages, aluminum is also an environmentally sustainable material. It is 100% recyclable, making it an eco-friendly option for aircraft interiors. Recycling aluminum requires significantly less energy compared to primary aluminum production, thereby reducing the carbon footprint associated with manufacturing. In conclusion, the combination of its lightweight nature, corrosion resistance, ease of fabrication, and sustainability makes aluminum sheets highly suitable for manufacturing aircraft interiors.

- Q:Can the aluminum sheets be used for manufacturing electronic heat sinks?

- Certainly! Electronic heat sinks can be manufactured using aluminum sheets. Due to its outstanding thermal conductivity and lightweight characteristics, aluminum has become a favored material for heat sinks. It facilitates the efficient dissipation and regulation of heat produced by electronic components. By easily molding and shaping aluminum sheets, the desired heat sink design can be achieved, thereby ensuring effective cooling for electronic devices.

- Q:Can aluminum sheets be used in electrical applications?

- Aluminum sheets have the capability to be employed in electrical applications. Due to its adeptness in conducting electricity, aluminum is frequently utilized in diverse electrical components and applications. In power transmission lines, bus bars, and electrical enclosures, aluminum sheets are frequently employed as conductive materials. Moreover, their exceptional thermal conductivity properties make them valuable in the production of capacitors, transformers, and heat sinks. Furthermore, aluminum sheets are lightweight and resistant to corrosion, rendering them appropriate for electrical applications where weight and durability are crucial considerations.

- Q:What is the classification of 6061106070 aluminum plate, which respectively represent what it means to ask God for help

- Three, the beginning of the aluminum manganese alloy, 3003, 3004, 3015 and so on, the use of a wide range, also known as rust aluminum. Four, the beginning of the four Department of aluminum is aluminum silicon alloy, on behalf of 4A01 five, the beginning of the aluminum magnesium alloy, there are 5052, 5083 and so on, the use of more than three series, the domestic manufacturers can do.

- Q:What is aluminium plate for?

- Two outdoor and indoor, outdoor curtain wall decoration, indoor ceiling (such as aluminum pinch plate, aluminum grille, aluminum hanging tablets, etc.), color diversity, but also can be made imitation wood grain, imitation marble and other colors, widely used

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Prepainted Coil with PVDF and Different Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords