Aluminium Polyester Oil Painted for Glass Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium Polyester Oil Painted for Glass Wall Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Polyester Oil Painted for Glass Wall:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

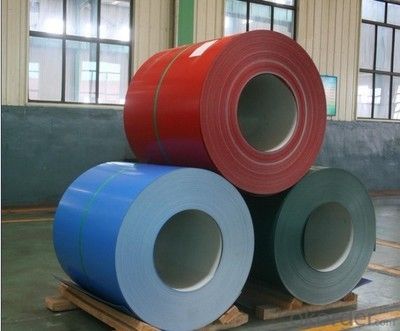

Images of the Aluminium Polyester Oil Painted for Glass Wall:

Aluminium Polyester Oil Painted for Glass Wall Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:The box doesn't tell me. I need to know because my gun range won't allow steel or aluminum cartridges

- Brand would help. Including aluminum tends to imply that the case construction is all that you are worried about. There are three common materials that cases are made from, aluminum, brass, and steel. If the case is clearly brass colored without a coating on it, it is brass. If it is a silvery metal, it is definitely aluminum, unless it is polished shiny, in which it would be a nickel plated brass case. Steel cases can be hard to determine visually. Many times they are coated with zinc, copper wash, other metals or lacquer. If a magnet will attract the case, it is steel, or at least definitely not brass. The range may be worried about steel core bullets. If a magnet will attract the bullet, it is steel cored.

- Q:What is the typical thickness of aluminum coils?

- The typical thickness of aluminum coils can vary depending on their intended use and application. However, in general, aluminum coils are available in a range of thicknesses, typically ranging from 0.006 inches (0.15 mm) to 0.25 inches (6.35 mm). The specific thickness required for a particular project or industry will depend on factors such as the desired strength, flexibility, and weight of the aluminum coils.

- Q:Can aluminum coils be used in the production of aluminum facades?

- Yes, aluminum coils can be used in the production of aluminum facades. Aluminum coils are commonly used as a raw material in the manufacturing process of aluminum facades. The coils are typically shaped, cut, and formed to create the desired design and dimensions of the facade. The use of aluminum coils provides durability, versatility, and ease of installation in the production of aluminum facades.

- Q:Can aluminum coils be painted or coated for aesthetic purposes?

- Aluminum coils have the potential to be painted or coated in order to enhance their visual appeal. The versatility of aluminum makes it a suitable material for easy painting or coating, resulting in an improved appearance. This process offers a multitude of color choices and finishes, allowing for personalization and attractiveness in numerous applications. Furthermore, the paint or coating serves as a safeguard against corrosion and weather damage, thereby prolonging the lifespan and durability of the aluminum coils. Nevertheless, it is crucial to select the appropriate paint or coating that is compatible with aluminum and appropriate for the intended purpose to achieve the best outcome.

- Q:How much is one square aluminum gate and five hard door?

- On the Alibaba website search "roll gate", there are many manufacturers, you can ask them.

- Q:How to calculate the dosage of paint for aluminum coil coating? If the weight is 1 ton, the density 2.71 and the thickness 0.12mm, how much paint is needed?

- Coating surface area S*0.12(thickness)*ρ(density) / solid(paint solid)=actual paint consumption brush and roller paint: 100% spray paint: calculated value*70%

- Q:A cube of solid aluminum has a volume of 1.00 m3 at 20°C. What temperature change is required to produce a 130 cm3 increase in the volume of the cube?

- The linear expansivity of aluminum is 23 x10^-6 /K. Bulk expansivity is 3 x 23 x10^-6 / k For 130 [cm^3] the temperature required is 130 [cm] ^3/ 3 x 23 x10^-6 = 0.00013/[3 x 23 x10^-6] = 1.88 K ========================= If each side of the cube of side 1m expands by e, then its new volume = [1+e]^3 = 1 + 3e + 3e^2 +e^3. Neglecting high powers of e as negligible, the increase in volume is 3e. But e = 23 x10^-6 x rise in temperature 3e = 3*23 x10^-6 x rise in temperature. Given 3e = 0.00013 0.00013= 3*23 x10^-6 x rise in temperature Rise in temperature = 0.00013 / 3*23 x10^-6 = 1.88 K

- Q:What are the different edge profiles available for aluminum coils?

- There are several different edge profiles available for aluminum coils, each serving a specific purpose or aesthetic preference. Some of the most common edge profiles include: 1. Square Edge: This is the most basic and straightforward edge profile, with sharp corners and a flat surface. It is often used for industrial applications where functionality is prioritized over aesthetics. 2. Round Edge: The round edge profile features a curved surface that eliminates sharp corners. This profile is commonly used in applications where safety is a concern, such as automotive parts or children's playground equipment. 3. Beveled Edge: The beveled edge profile is characterized by a slanted or angled surface. It is often chosen for architectural purposes, as it adds a sleek and modern look to aluminum coils. Additionally, the beveled edge helps to minimize the risk of sharp edges and potential injuries. 4. Full Radius Edge: This edge profile features a smooth, rounded surface that extends along the entire length of the coil. Full radius edges are often preferred for applications where the coil will come into contact with other materials, as they reduce the risk of damage or scratching. 5. Hemmed Edge: A hemmed edge is created by folding the edge of the coil back onto itself, resulting in a double layer of metal. This profile is commonly used in applications where a strong and durable edge is required, such as in the manufacturing of appliances or cabinets. 6. Tapered Edge: The tapered edge profile gradually narrows the width of the coil towards the edge, creating a tapered or sloping appearance. This profile is often chosen for architectural or decorative purposes, as it adds visual interest and can make a space appear more dynamic. It is important to note that the availability of these edge profiles may vary depending on the manufacturer and the intended application of the aluminum coil. Therefore, it is recommended to consult with the supplier or manufacturer to determine the specific edge profiles that are available for a particular coil.

- Q:What are the typical thickness tolerances for aluminum coils?

- The typical thickness tolerances for aluminum coils can vary depending on the specific manufacturing standards and requirements of the industry. However, in general, the thickness tolerances for aluminum coils range from +/- 0.001 to 0.005 inches. These tolerances ensure that the thickness of the aluminum coils remains within acceptable limits to meet the desired specifications and applications. It is important to note that the specific tolerances may differ based on the intended use of the aluminum coils, such as for architectural, automotive, or aerospace purposes.

- Q:Are aluminum coils suitable for roofing applications?

- Indeed, roofing applications can indeed make use of aluminum coils. Aluminum, as a material, possesses the qualities of being lightweight and durable, thus making it advantageous for roofing projects. In terms of corrosion resistance, aluminum excels, which is crucial in safeguarding roofs from weather elements like rain, snow, and UV radiation. Furthermore, aluminum is fire-resistant, ensuring safety in roofing applications. Moreover, aluminum coils possess high malleability, allowing for effortless shaping and installation on various roof designs. They are also obtainable in an extensive array of colors and finishes, providing aesthetic choices for different architectural styles. All in all, the durability, versatility, and aesthetic appeal of aluminum coils contribute to their popularity in roofing applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Polyester Oil Painted for Glass Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords