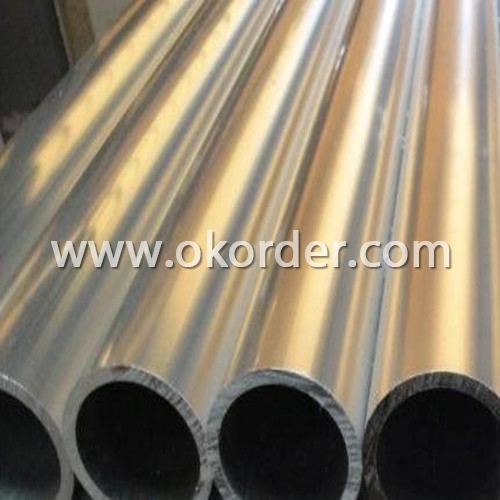

Aluminium Pipes 8XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Pipes 8XXX

Alloy Number | AA 8XXX |

Temper | O, F,H112,T4,T5,T6,T3,T8 |

Thickness | 0.5-50mm |

Length | <=13m |

Diameter | Outer: 9-500mm |

Standard | GB/5237.2-2004, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Pipes 8XXX

Aluminum pipes are widely used for building construction, housing decorations, industry & agriculture & architecture usage etc.

3. Packaging & Delivery of Aluminum Pipes 8XXX

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Pipes 8XXX

Casting--extruding--cutting--coating—further processing--packing

- Q:Why is the aluminum tube welded with stainless steel gasket ring?

- In fact, the butt welding of steel pipe, in the inner ring of the pipe with an annular gasket, the quality of welding is also a good guarantee. Argon arc welding is commonly used in aluminum alloy welding. No matter the MIG welding or by non consumable (TIG) welding, when the thickness of thin aluminum, the weld pool will because the material thickness is small and the formation of penetration, the melting temperature of aluminum is only 740 degrees, and the melting temperature of stainless steel has reached 1500 degrees, it can be a protective effect on melting the welding pool makes it easy to operate.

- Q:How can the refrigerator aluminum pipe leak?

- 1, the welding of aluminum pipe is more troublesome, and generally replace the new evaporator. Although there is a leak freezer tube can be welded, but not the good point, near the emergence of a new leak, it was suggested to change the new evaporator.

- Q:What are the different pressure ratings available for aluminum pipes?

- The pressure ratings of aluminum pipes differ based on their dimensions and thickness. Typically, aluminum pipes can be rated from 150 psi to 500 psi. Nevertheless, it is crucial to acknowledge that these ratings may change depending on the specific usage and adherence to industry norms. Consequently, consulting the manufacturer or referring to applicable codes and standards is imperative in order to ascertain the precise pressure rating for a given aluminum pipe.

- Q:Are aluminum pipes suitable for desalination plants?

- Indeed, desalination plants can benefit from the suitability of aluminum pipes. With its lightweight nature and resistance to corrosion, aluminum proves itself capable of enduring the challenging circumstances within such facilities. The conditions prevalent in desalination plants, characterized by high pressure and corrosive seawater, pose no threat to aluminum. Thanks to their remarkable resistance to saltwater corrosion, aluminum pipes warrant trust in effectively transporting saltwater throughout the desalination process. Furthermore, the installation process for aluminum pipes is hassle-free, demanding minimal upkeep yet ensuring a lengthy lifespan. As a result, desalination plants can rely on the cost-effectiveness of aluminum pipes.

- Q:Do aluminum pipes require insulation?

- Yes, aluminum pipes generally require insulation to prevent heat transfer, condensation, and energy loss.

- Q:What causes aluminium tubes to peel and blacken?

- The phenomenon is common when the aluminum pipe is connected with other metals and has electrolyte flow. This is because the electrochemical reaction results in the formation of a galvanic cell. Aluminum is the anode, and the surface of the aluminum tube is oxidized to cause blackening and peeling

- Q:How do aluminum pipes compare to carbon steel pipes in terms of cost?

- In comparison to carbon steel pipes, aluminum pipes are generally pricier. This is mainly because the manufacturing of aluminum incurs higher costs compared to carbon steel. Furthermore, the production of aluminum pipes necessitates more intricate techniques, like extrusion or welding, which further contribute to the overall expenses. Conversely, carbon steel pipes are usually less costly due to the ample availability of raw materials and the simpler manufacturing procedures employed. Nevertheless, it is crucial to acknowledge that the cost comparison might fluctuate based on factors such as pipe size, grade, and market conditions.

- Q:Can aluminum pipes be used for heat exchangers?

- Indeed, heat exchangers can utilize aluminum pipes. The exceptional thermal conductivity and corrosion resistance of aluminum make it a prevalent option for constructing heat exchangers. Aluminum pipes possess lightweight, resilient characteristics and effectively facilitate heat transfer between two fluids or gases. The remarkable thermal conductivity of aluminum ensures efficient heat transfer, rendering it an optimal selection for heat exchanger purposes. Furthermore, industries that prioritize weight reduction, such as aerospace and automotive, frequently favor aluminum pipes due to their lightweight composition.

- Q:Vanward gas 6B water heater is a copper tube or aluminum tube?

- Vanward gas water heater 6B practical model is JSD12-6B, is the flue type water heater, but also the state does not allow the use of gas water heater (as well as part of the rental housing in use, the reason is cheap, this is the old product), the Vanward factory has long been discontinued. The gas water heater began to use the oxygen free copper water tank in recent years, so the Vanward gas water heater is made of aluminum alloy water tank, not copper.

- Q:Can aluminum pipes be used in HVAC systems?

- Yes, aluminum pipes can be used in HVAC systems. Aluminum is a lightweight and corrosion-resistant metal, making it an ideal choice for HVAC applications. Aluminum pipes are commonly used for air conditioning and refrigeration systems, as well as in heat exchangers and condensers. They offer excellent thermal conductivity, which allows for efficient heat transfer, and they are also durable and long-lasting. Additionally, aluminum pipes are easy to work with, as they can be easily cut, bent, and shaped to fit specific requirements. Overall, aluminum pipes are a reliable and cost-effective option for HVAC systems.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminium Pipes 8XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords