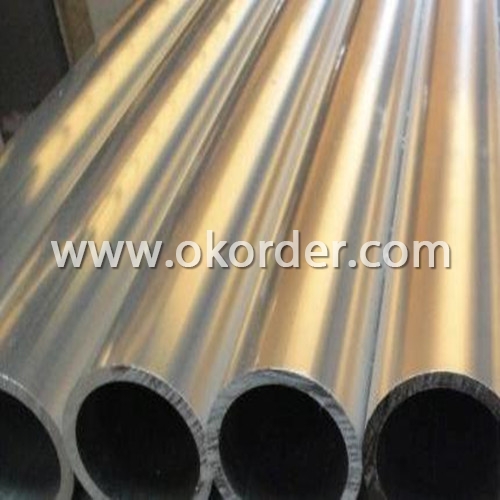

Aluminium Pipes 3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Pipes 3XXX

Alloy Number | AA 3XXX |

Temper | O, F,H112,T4,T5,T6,T3,T8 |

Thickness | 0.5-50mm |

Length | <=13m |

Diameter | Outer: 9-500mm |

Standard | GB/5237.2-2004, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Pipes 3XXX

Aluminum pipes are widely used for building construction, housing decorations, industry & agriculture & architecture usage etc.

3. Packaging & Delivery of Aluminum Pipes 3XXX

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Pipes 3XXX

Casting--extruding--cutting--coating—further processing--packing

- Q:Expert: about 100 caliber aluminum tube, manual argon arc welding, single-sided welding, double sided forming technology. And welding process and welding method ~!

- Aluminum tube size 57*4*100; thank you all experts to answer the aluminum tube butt manual tungsten arc welding; single-sided welding double-sided forming technology......

- Q:What are the different diameters available for aluminum pipes?

- The manufacturer and specific requirements can cause variation in the available diameters for aluminum pipes. Nonetheless, aluminum pipes typically span a range of diameters starting from as small as 0.25 inches (6.35 mm) and extending to larger sizes like 12 inches (304.8 mm) or even larger. The intended use of the aluminum pipes can also influence the specific diameter options available since various industries and applications may necessitate specific sizes. To ensure that your specific needs are met, it is advisable to consult the manufacturer or supplier and ascertain the precise range of diameters for aluminum pipes.

- Q:6063, aluminum pipe bending performance, hardness of the best value?

- Two is the service life advantages: from the inner wall of the aluminum tube, as the refrigerant does not contain moisture, the copper and aluminum connecting pipe inner wall will not corrode.

- Q:What are the different cutting methods for aluminum pipes?

- There are several cutting methods for aluminum pipes, including using a hacksaw, pipe cutter, bandsaw, or circular saw with a metal-cutting blade. Laser cutting and plasma cutting are also commonly used for precision cuts. Each method has its advantages and suitability depending on the pipe's size, thickness, and desired cut quality.

- Q:What ion is corrosive to the aluminum tube?

- Too much, mainly is the strong oxidizing ion such as hydrogen ion, iron ion, nitrate ion, permanganate ion and so on

- Q:Are aluminum pipes suitable for vacuum systems?

- Yes, aluminum pipes can be suitable for vacuum systems depending on the specific requirements and conditions of the system. Aluminum is a lightweight and corrosion-resistant material, making it a popular choice for various applications, including vacuum systems. However, it is important to consider factors such as the level of vacuum required, the temperature range, and the potential for outgassing. In certain cases, aluminum may not be the best choice, especially for high vacuum applications or systems that require extremely low levels of outgassing. In such cases, materials like stainless steel or titanium may be more suitable. It is crucial to consult with experts or engineers who specialize in vacuum systems to determine the most appropriate material for a specific vacuum system.

- Q:How are aluminum pipes manufactured?

- Aluminum pipes are typically manufactured through a process called extrusion. In this process, a cylindrical aluminum billet is heated and forced through a shaped die using a hydraulic press. As the aluminum passes through the die, it takes the shape of the desired pipe, which is then cooled and cut to the required length. This extrusion method allows for the production of aluminum pipes with consistent dimensions, high strength, and good surface finish.

- Q:The length of the aluminum tube is about 180mm, the diameter is 19mm, and the wall thickness is about 1mm. It should be bent into the radian of R300. No deformation

- Provide two ways for youThe 1. is what they say is to fill in the sand, the deformation rate should be within 5%, but the efficiency is slow2. is a new type of mandrel bending machine, direct cold bending, deformation rate of 5%, high efficiencyPS: do not use mandrel bending machine, because the mandrel and tube friction, tube wall will be thinned, roundness will be very serious deformation (because your pipe wall thin because), if the tube through objects or liquid, will form dirt

- Q:Can aluminum pipes be used for conveyor systems?

- Yes, aluminum pipes can be used for conveyor systems. Aluminum is lightweight, corrosion-resistant, and has good strength properties, making it suitable for conveying a wide range of materials in various industries.

- Q:Hello, there's a question I'd like to ask. 'I'd like an aluminum pipe bender', but it won't do '

- LZ: what style of pipe bender do you need? Do you need to wear a mandrel? What's the bending radius? What are the pipe diameter and wall thickness? There are two kinds of pipe bending machines on the market, one is the straight top bending pipe bender, and the other is the rotary pull bending pipe bender, so the bend way is very important. Secondly, the choice of bend control method.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 2004 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminium Pipes 3XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords